111-F00 Page 11/16

MAINTENANCE:

PUSHROD INSTALLATION

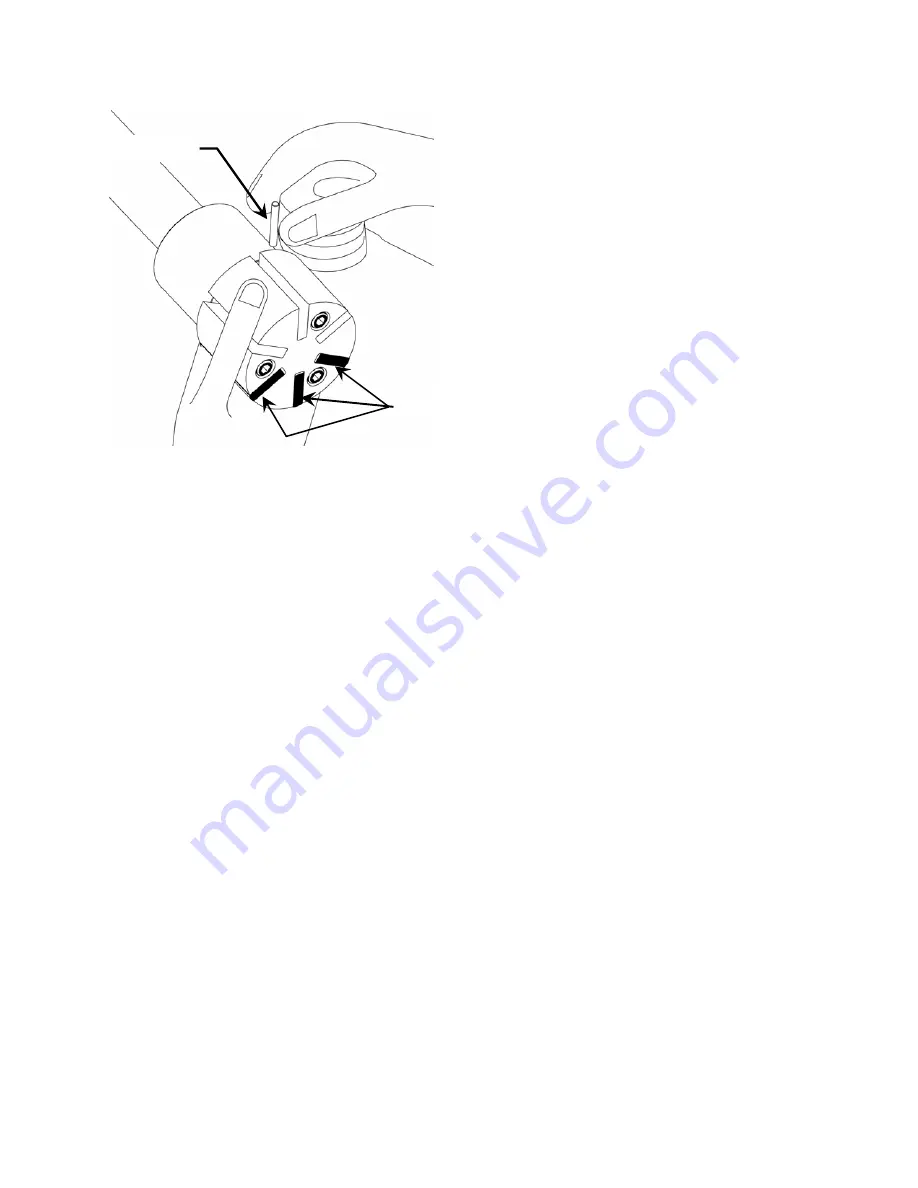

Figure 11 – Pushrod Installation

6. Insert the vanes into the bottom three rotor slots with the

relief grooves facing in the direction of pump rotation,

and with the rounded edges outward. See Figures 6 &

11.

7. Hold the three bottom vanes in place while inserting the

three push rods (77). See Figure 11. Note: A small

amount of grease may be used to help hold the pushrod

in the rotor during assembly.

8. Installing Seal Rotating Elements

Refer to the seal manufacturer’s instructions for detailed

removal and replacement instructions.

Mechanical Seal type 9

a. Apply a small amount of Flowserve Pac-Ease™ or

equivalent water based lubricant on the shaft between

the shaft end and the rotor

b. Slide the seal rotating assembly (153B) over the shaft

with the rotating face away from the rotor until contact

is made with the large diameter of the shaft. Seal

spacer is not needed.

c. Tighten set screws and remove seal spacer clips per

manufacturer’s directions.

d. After the bottom vanes and push rods are installed,

carefully insert the driven end of rotor and shaft into

the cylinder.

e. Clean the polished face of the seal with a clean tissue

and alcohol before reassembly.

Mechanical Seal Type 16

a. After the bottom vanes and push rods are installed,

carefully insert the driven end of rotor and shaft into

the cylinder.

b. Apply a small amount of Flowserve Pac-Ease™ or

equivalent water based lubricant on the shaft between

the shaft end and the rotor.

c. Install the seal spacer (82) over the shaft until it

bottoms out on the large diameter of the shaft.

d. Slide the seal rotating assembly (153B) over the shaft

with the rotating face away from the rotor until contact

is made with the seal spacer.

e. Clean the polished face of the seal with a clean tissue

and alcohol before reassembly.

9. Install the remaining vanes by rotating the shaft until an

empty vane slot is in the 12 o’clock position, ensuring

that the rounded edge is UP, and the relief grooves are

facing towards the direction of rotation. See Figure 6.

Repeat until all vanes have been installed. This method

of vane installation ensures the push rods do not fall out

of their rotor slots.

10. Install Stationary Seal Elements

Mechanical Seal type 9, 16

a. Apply a small amount of lubricant in the seal access of

the bearing adjuster (188).

b. Install a new stationary seat and O-ring into the

bearing adjuster until fully bottomed out.

Type 9 only - align slot in stationary seat with anti-

rotation pin (25A) in bearing adjuster (188) before

inserting stationary seat.

c. Clean the polished face with a clean tissue and

alcohol.

11. Install a new O-ring (51) onto the bearing adjuster (188)

12. Lubricate the O-ring seal area on the bearing housing

(57) with a light coating of oil.

13. Start the bearing adjuster (188) (with stationary seal

elements installed) over the shaft, being careful not to

damage the seal with the shaft end.

14. Screw the bearing adjuster (188) to the bearing housing

(57) until they are flush. Be sure that the 2 setscrews

(189) are not interfering with the flush fit of the bearing

adjuster to the bearing housing.

PUSHROD

VANES

Summary of Contents for 111-F01

Page 15: ...111 F00 Page 15 16 NOTES...