111-F00 Page 6/16

OPERATION

FLUSHING THE PUMP

NOTICE:

If flushing fluid is to be left in the pump for an extended

time, it must be a lubricating, non-corrosive fluid. If a

corrosive or non-lubricating fluid is used, it must be

flushed from the pump immediately.

To flush the pump, run the pump with the discharge valve

open and the intake valve closed. Bleed air into the pump

through the intake gauge plug hole or through a larger

auxiliary fitting in the intake piping. Pump air for 30 second

intervals to clean out most of the pumpage.

1. Run a system compatible flushing fluid through the pump

for one minute to clear out the remainder of the original

pumpage. The valve in the discharge line should be

restricted to build up 10 psi (0.7 bar) to force flushing

liquid through the bearing seal chamber.

2. To remove the flushing fluid, follow step 1 above.

3. After flushing the pump some residual fluid will remain in

the pump and piping.

4. Properly dispose of all waste fluids in accordance with

the appropriate codes and regulations.

OPTIONAL PUMP RELIEF VALVE:

Hazardous pressure

can cause personal

injury or property

damage

An external bypass valve and/or an

internal relief valve MUST be installed in

the system to protect the pump from

excessive pressure.

Hazardous pressure

can cause personal

injury or property

damage

.

Incorrect bypass valve or internal relief

valve settings can cause pump

component failure, personal injury, and

property damage.

1. Blackmer ProVane pumps may or may not be fitted with

an internal relief valve. If an internal relief valve is not

supplied, an external bypass valve must be used.

2. The pump’s internal relief valve is designed to protect

only the pump from excessive pressure and must not be

used as a system pressure control valve.

3. Internal bypassing of liquid elevates liquid temperature.

Internal relief valve should only be used for brief periods

and for differential pressures below 125 psi. For

extended periods, an external bypass returned to source

must be used.

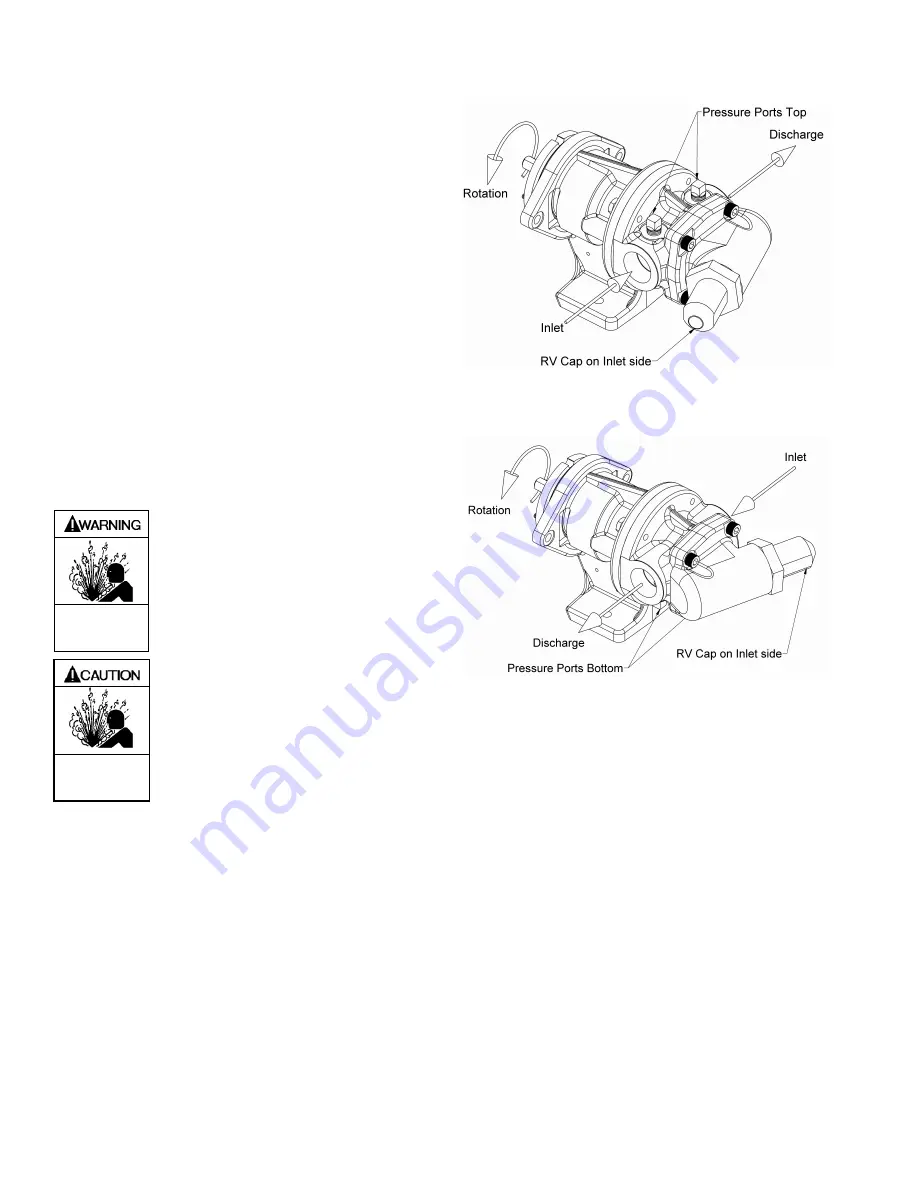

4. The pump relief valve cap must be on the inlet side of the

pump. If pump relief valve is installed improperly, it will

not operate and a component failure may result. See

Figures 4 and 5.

Fig 4 Right Hand Orientation

Fig 5 Left Hand Orientation

Summary of Contents for 111-F01

Page 15: ...111 F00 Page 15 16 NOTES...