111-F00 Page 9/16

MAINTENANCE:

PUMP DISASSEMBLY

NOTICE:

Follow all hazard warnings and instructions provided in

the “Maintenance” section of this manual.

NOTE:

The numbers in parentheses following individual parts

indicate reference numbers on the Pump Parts List.

1. Flush the pump per instructions in this manual. Drain and

relieve pressure from the pump and system as required.

2. Starting on the inboard (driven) end of the pump, clean

the pump shaft thoroughly, making sure the shaft is free of

nicks and burrs. This will prevent damage to the

mechanical seal when removed.

3. Remove the head cap screws (21). Gently pry the head

away from the casing using two large screwdrivers. The

head O-ring should come off with the head assembly.

4. Remove locknut and lock washer (24A and 24B):

a. Bend up the engaged lock washer tang and rotate the

locknut counterclockwise to remove it from the shaft.

b. Slide the lock washer off the shaft. Inspect the lock

washer for damage and replace as required.

5. Remove the rotor and shaft (13) from the casing. While

one hand is pushing the shaft, the other hand should be

cupped underneath the rotor to prevent the vanes (14)

and pushrods (77) from falling out. As the rotor & shaft

are removed further, carefully support the shaft so it does

not drop and damage the sleeve bearing or finished

surfaces of the shaft or the rotating seal face as it is

removed. Carefully set the rotor and shaft aside for future

vane replacement and reassembly.

6. To remove the cylinder. Lay the pump on end with the

bearing housing facing upward and remove the 4 cap

screws (21). Lift off the bearing housing and remove the

cylinder O-ring (71).

7. The mechanical seal rotating assembly will come out with

the shaft. The stationary seat and stationary seal ring

need to be removed from the bearing adjuster (188).

8. Carefully pry the stationary seal elements (153A) from the

bearing adjuster (188). Be sure not to scratch the seal

face or damage the elastomer seal seat.

9. Remove the ball bearing adjuster (188) by loosening the

set screws (189) and turning it counter clockwise with a

strap wrench or spanner wrench.

10. If necessary for replacement, remove the ball bearing

(24C) from the bearing adjuster. Turn the bearing adjuster

so the threaded side is up. Using an appropriately sized

arbor press remove the bearing (24C) from the bearing

adjuster. Discard old bearing and replace with new one.

See step 2 of “PUMP ASSEMBLY”

11. If the sleeve bearing is worn or damaged.

a. Remove the sleeve bearing (24) from the bearing

housing (57) using an appropriately sized arbor press.

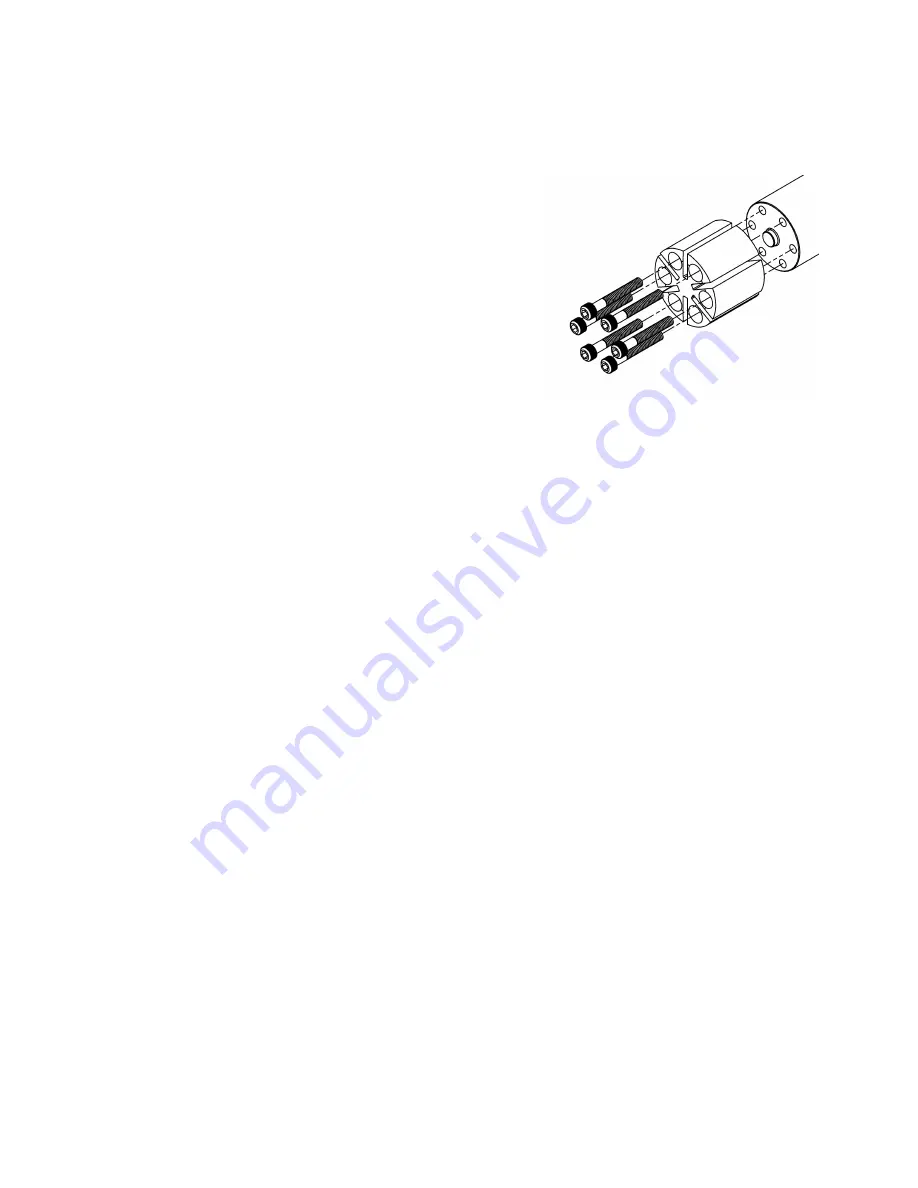

12.

Only disassemble rotor & shaft if necessary for part

replacement

. Disassemble the rotor (13B) and shaft

(13A) by removing the six cap-screws (13C). See figure

7.

Figure 7

PARTS REPLACEMENT

1. If any of the O-rings have been removed or disturbed

during disassembly, they need to be replaced with new

O-rings.

NOTE:

PTFE O-rings should be heated in hot water to aid

installation.

2. Excessive or continuous leakage from around the seal

housing or in the bearing housing may be an indication of

a damaged mechanical seal. If a mechanical seal has

been leaking, it is recommended the entire seal be

replaced. Refer to "General Pump Troubleshooting" for

possible causes of seal leakage.

3. Inspect bearings for wear and replace as necessary.

Summary of Contents for 111-F01

Page 15: ...111 F00 Page 15 16 NOTES...