MAINTENANCE

11

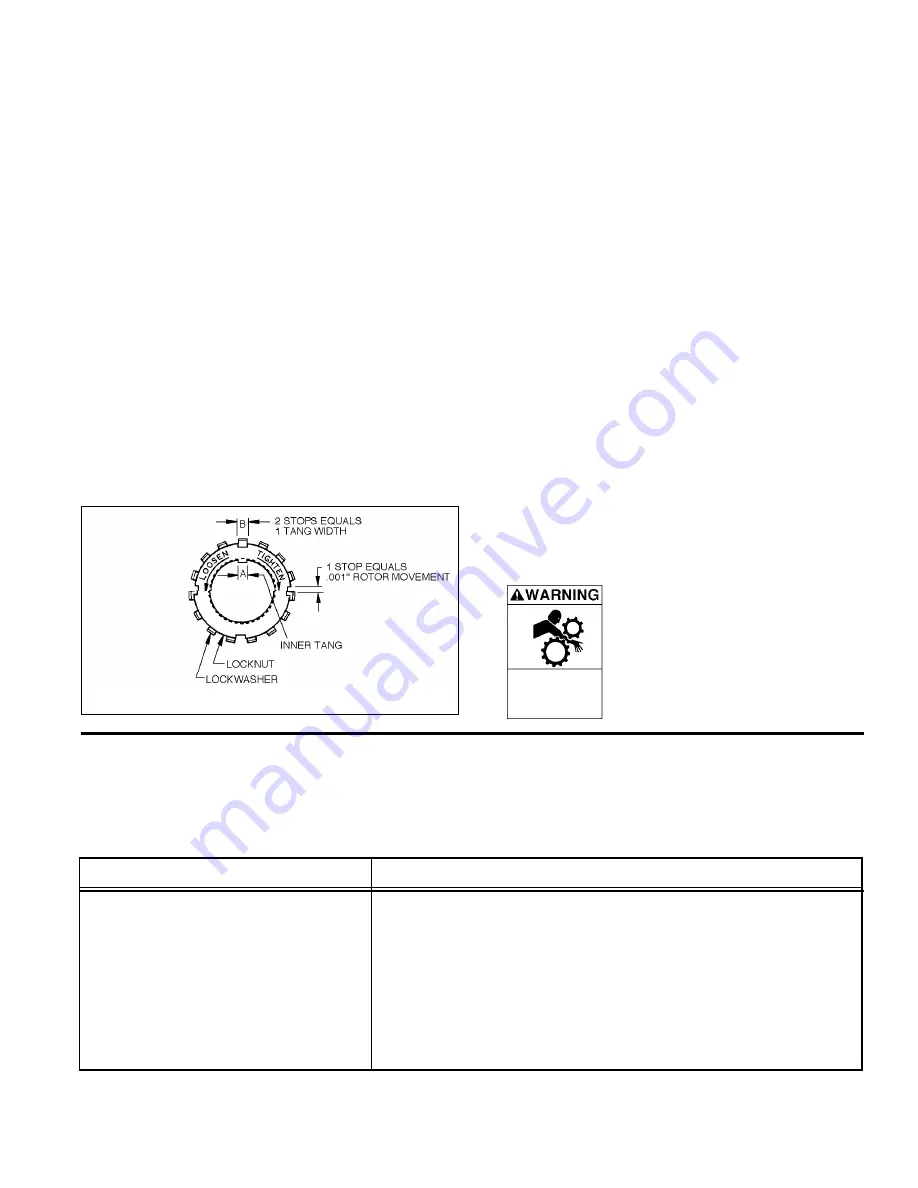

Figure 10 - Locknut Adjustment

13.

LOCKNUT ADJUSTMENT

It is important that the bearing locknuts (24A) and

lockwashers (24B) be installed and adjusted properly.

Overtightening locknuts can cause bearing (24) failure or a

broken lockwasher tang. Loose locknuts will allow the rotor

to shift against the discs (71), causing wear. See Figure 10.

a. On both ends of the pump shaft, install a lockwasher

(24B) with the tangs facing outward, followed by a

locknut (24A) with the tapered end inward. Ensure the

inner tang "A" of the lockwasher is located in the slot in

the shaft threads, bending it slightly, if necessary.

b. Tighten both locknuts (24A) to ensure that the bearings

(24) are bottomed in the head recess. DO NOT over-

tighten and bend or shear the lockwasher inner tang.

c. Loosen both locknuts (24A) one complete turn.

d. Tighten one locknut (24A) until a slight rotor drag is felt

when turning the shaft by hand.

e. Back off the locknut (24A) the width of one lockwasher

tang "B". Secure the locknut by bending the closest

aligned lockwasher tang into the slot in the locknut. The

pump must turn freely when rotated by hand.

OPERATION WITHOUT GUARDS IN

PLACE CAN CAUSE SERIOUS

PERSONAL INJURY, PROPERTY

DAMAGE, OR DEATH.

Do not operate

without guard

in place.

f. Tighten the opposite locknut (24A) by hand until it is

snug against the bearing (24). Then, using a spanner

wrench, tighten the nut the width of one lockwasher

tang. Tighten just past the desired tang, then back off

the nut to align the tang with the locknut slot. Secure

the nut by bending the aligned lockwasher tang into the

slot in the locknut. The pump must continue to turn

freely when rotated by hand.

g. To check adjustment, grasp the locknut (24A) and

lockcollar (24B) with fingers and rotate back and forth.

If this cannot be done, one or both locknuts are too tight

and must be alternately loosened one stop at a time

(.001" - 25 microns). Begin by loosening the locknut

adjusted last.

14. Inspect the grease seal (104) for wear or damage and

replace as required. Grease the outside diameter of the

grease seal and push it into the inboard bearing cover (27)

with the lip of the seal inward.

15. Attach a new bearing cover gasket (26) and the bearing

cover (27) to the inboard head (20). Make sure the grease

fittings (76) are accessible. Install and torque the bearing

cover capscrews (28) to 30 lbs ft (47 Nm).

16. Install the grease seal (104) in the outboard bearing cover

(27) as instructed in step 14.

17. Attach a new bearing cover gasket (26) and the outboard

bearing cover (27) to the outboard head (20). Make sure

the grease fittings (76) are accessible. Install and torque

the bearing cover capscrews (28) to 30 lbs ft (47 Nm).

18. Attach the shaft protector (186) to the non-driven shaft end.

GENERAL PUMP TROUBLESHOOTING

NOTICE:

MAINTENANCE SHALL BE PERFORMED BY QUALIFIED TECHNICIANS ONLY, FOLLOWING

THE APPROPRIATE PROCEDURES AND WARNINGS AS PRESENTED IN THIS MANUAL.

SYMPTOM

PROBABLE CAUSE

Pump Not Priming

1. Pump not wetted.

2. Worn vanes.

3. Internal control or inlet valve closed.

4. Strainer clogged.

5. Inlet line or valves clogged or too restrictive.

6. Broken drive train (truck mounted pumps).

7. Pump vapor-locked.

8. Pump speed too low for priming.

9. Relief valve partially open, worn or not seating properly.

Pump Troubleshooting continued on back page.