102-A00 page 10/16

MAINTENANCE

VANE REPLACEMENT AND/OR

COMPLETE PUMP DISASSEMBLY

NOTICE:

Follow all hazard warnings and instructions provided in

the “Maintenance” section of this manual.

Always use a lifting device capable of

supporting the full weight of the pump

assemblies.

Heavy assemblies can

cause personal injury

or porperty damage.

NOTICE:

Use a hoist and appropriate sling or lifting lugs attached

to the baseplate to lift the entire pump assembly.

Eyebolts attached to the pump, gearbox, or motor must

be used to lift that particular component only.

NOTICE:

Use a hoist and eyebolts installed in the threaded holes

located in the heads, discs, rotor and casing to lift the

heavy pump parts.

Note: If a seal or vanes are to be replaced, the pump may

be left in the upright position. If the rotor-shaft or liner is

to be removed, the pump will have to be placed on its

side for some operations.

1. Flush the pump per instructions in this manual. Drain

and relieve pressure from the pump and system as

required. A 3/4" drain plug (29) is fitted in each head.

2.

With the pump upright (shaft horizontal).

Clean the

pump shaft thoroughly, making sure the shaft is free of

nicks and burrs. This will prevent damage to the

mechanical seal when the inboard hub or head assembly

is removed.

3. Remove the inboard bearing cover capscrews (28) and

slide the inboard bearing cover (27A) and gasket (26) off

the shaft. Discard the bearing cover gasket.

4. Removing the locknuts and lockwashers (24A and 24B):

a. Bend up the engaged lockwasher tang and rotate the

locknut counterclockwise to remove it from the shaft

b. Slide the lockwasher off the shaft. Inspect the

lockwasher for damage and replace as required.

5. Move to the outboard side of the pump and remove the

outboard bearing cover capscrews (28) and slide the

outboard bearing cover (27) and gasket (26) off the shaft.

Discard the bearing cover gasket.

6. Bend up the engaged lockwasher tang and tighten the

locknut (24A) on outboard end until shaft cannot be

rotated by hand. This will ensure proper rotor/shaft (13)

alignment during reassembly.

7. Return to the inboard side of the pump and wrap the

shaft threads with tape to ensure that grease seal (104A)

is not damaged upon hub removal.

8. Remove the capscrews (21A) from the inboard hub

(20C) and slide the hub assembly off the shaft. The

bearing (24), grease seal carrier assembly (104B, 104A

and 104C), stationary seat (153B) and stationary O-ring

(153D) of the mechanical seal will come off with the hub.

a. Pull the bearing (24) and grease seal carrier

assembly (104B, 104A and 104C) from the housing in

the hub.

b. If worn or damaged, remove the grease seal (104A)

from the carrier (104B).

c. To remove the mechanical seal stationary seat

(153B), remove the seal retaining screws and

washers (153Q, 153R). Gently push the backside of

the stationary seat from the seal recess. Place a cloth

under the seal to avoid damage. Be careful not to

contact the polished face of the seal during removal.

Remove and discard mechanical seal stationary O-

ring.

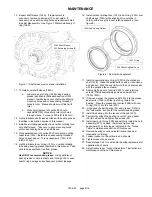

9. Remove the remaining mechanical seal parts, including

the seal spring holder, springs, retaining ring, rotating O-

ring and face (153G, 153H, 153N, 153L, 153F) from the

shaft sleeve (154) by removing capscrews (153J).See

Figure 6. Take care to protect the carbon rotating face

from damage during disassembly. Remove and discard

rotating O-ring.

10. Inspect shaft sleeve (154A). If replacement is

necessary, remove capscrews (155), set aside. If

necessary, use seal mounting holes as jackscrew holes

to assist disassembly. See Figure 7 Discard stationary O-

ring (154B).

11. To install new shaft sleeve (154A):

a. Lubricate inner O-ring (154B) using bearing grease

identified in lubrication section of this manual. Install

sleeve over shaft while aligning mounting holes with

corresponding threaded holes in rotor. Sleeve should

mount flush with rotor

b. Place small amount of Loctite # 220 onto capscrews

(155), thread fully into rotor holes through sleeve.

Torque to 200 inlbf (22.6 Nm).

12. Remove the head capscrews (21). If necessary, place

head capcrews in the two tapped holes near the outer

rim of the head and tighten until the head separates from

the casing. Use a hoist to remove the head from the

casing, being careful not to damage the shaft.

13. Remove the head O-ring (72) and disc (71). If needed,

threaded holes are provided in the disc to break it free.

14. Remove the top vane then rotate the shaft by hand to

bring the next vane to the top until all the vanes have

been removed. If the vanes are swollen or jammed in

their slots, the rotor-shaft must be removed.

15. If doing a vane-only replacement, skip to step 10 of

COMPLETE PUMP ASSEMBLY section of this manual

for pump reassembly

16. If full pump disassembly required, loosen and remove

outboard locknut (24A) and lockwasher (24B).

17. Set the pump on its side (shaft vertical) with the shaft

pointing up.

18. Attach a hoist to rotor-shaft, lift it out and set it aside.

The pushrods, and rotating portions of the seal will come

out with the rotor-shaft..

19. Set the pump upright (feet down).

20. Remove the outboard head components as described for

the inboard side in steps 7-12.

21. Attach a hoist to the liner. Use a block of wood or piece

of brass against the end of the liner, and drive the liner

out of the casing with a hammer by tapping the outside

diameter of the liner.