102-A00 page 11/16

MAINTENANCE

COMPLETE PUMP ASSEMBLY

Before reassembling the pump, inspect all component

parts for wear or damage, and replace as required. Wash

out the bearing/seal recess of the head and remove any

burrs or nicks from the rotor and shaft. Remove any

burrs from the liner.

NOTICE:

Use a hoist and eyebolts installed in the threaded holes

located in the heads, discs, rotor and casing to lift the

heavy pump parts.

Always use a lifting device capable of

supporting the full weight of the pump

assemblies.

Heavy assemblies can

cause personal injury

or porperty damage.

1. Set the pump casing upright (feet down).

2. The liner must be installed in the pump casing with the

word “INTAKE” cast on the liner toward the intake port of

the pump casing.

Align the keyway in the top of the liner with the pin in the

top of the casing.

Uniformly tap the outer edge of the liner with a rubber

mallet to fully insert into the casing.

3.

Start assembly on the

OUTBOARD

non-driven side of

the pump:

For a CLOCKWISE rotation pump, the INTAKE port is to

the

left

.

For a COUNTERCLOCKWISE rotation pump, the

INTAKE port is to the

right

.

Loosely assemble the outboard disc (71) and head (20)

to the casing (12). The bearing, seal, O-rings, etc. will be

installed later.

4. Set the pump on its side with the outboard head DOWN.

Figure 5 – Vane Installation

5. Remove the vanes (14) and push rods (77) from the rotor

and shaft assembly. Inspect for wear and damage, and

replace as follows:

a. Insert the three push rods (77) into the rotor.

b. Using a hoist, lower the non-driven end of the rotor

and shaft into the open side of the pump casing,

being careful not to hit the disc with the shaft.

c.

Insert the vanes into the rotor slots with the relief

grooves facing in the direction of pump rotation, and

with the rounded edges outward. See Figure 5.

6. If shaft sleeve (154A) previously removed, lubricate inner

O-ring (154B) using bearing grease identified in

lubrication section of this manual. Install sleeve over

shaft while aligning mounting holes with corresponding

threaded holes in rotor. Sleeve should mount flush with

rotor

7. Place small amount of Loctite # 220 onto capscrews

(155), thread fully into rotor holes through sleeve.

Torque to 200 inlbf (22.6 Nm).

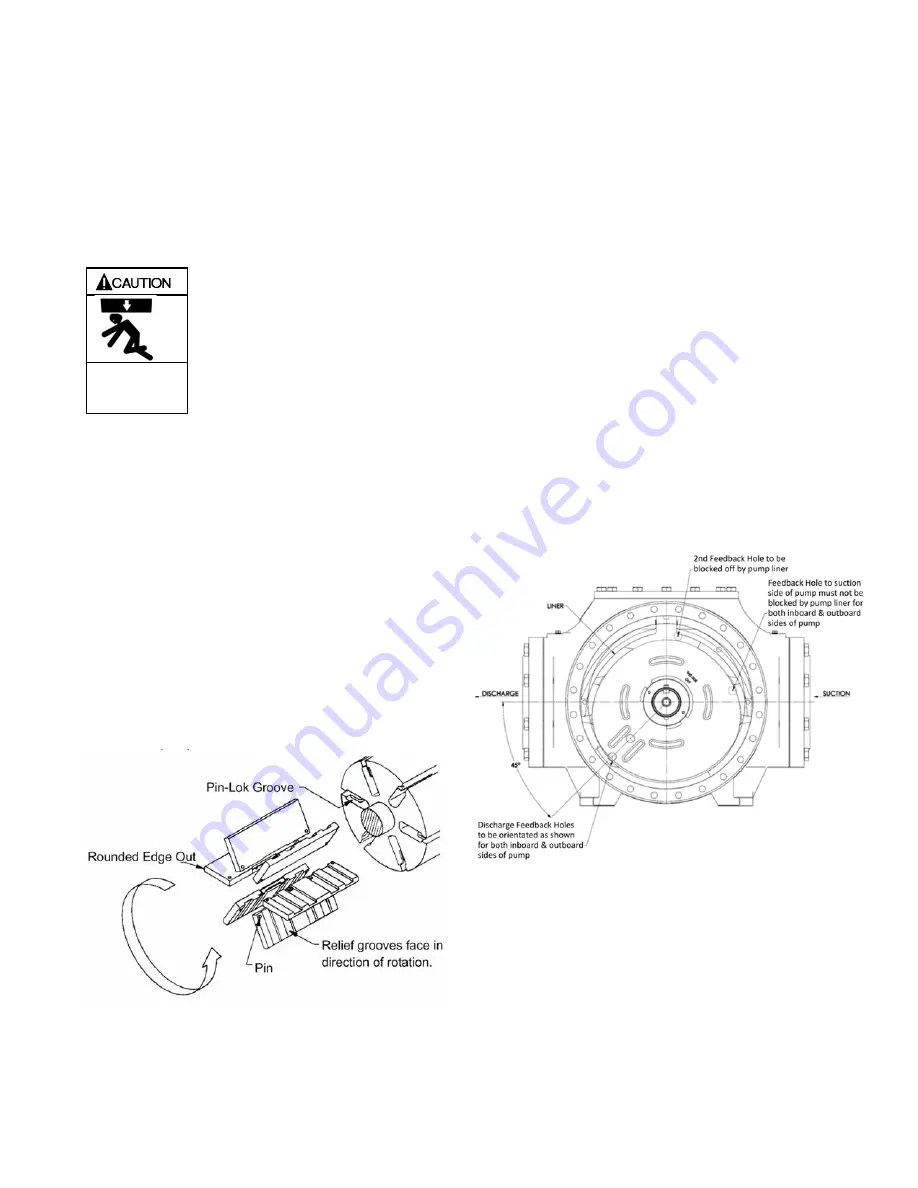

8. Using a hoist, install the disc in the casing with the

smooth side of the disc towards the casing (seal cavity

outward) and the pressure relief hole 45 degrees

downward from the discharge side of the casing. The

seal cavity feedback hole should be exposed into inlet

area of pump. (SEE FIGURE 9). There exists a 2

nd

feedback hole in each disc which should be fully covered

by the liner near the seal point when properly oriented.

Figure 9 – Disc Orientation

9. Install a new head O-ring (72).

10. Using a hoist, carefully attach the head (20) to the casing

with the head drain hole towards the bottom of the pump.

Install and tighten the head capscrews (21).

11. Lightly lubricate shaft sleeve surface with bearing grease

identified in lubrication section of this manual.

12. Install seal rotating assembly minus carbon rotating face

onto shaft sleeve. Take care to align mounting holes

with corresponding holes on shaft sleeve.