102-A00 page 12/16

MAINTENANCE

13. Place small amount of Loctite # 220 onto seal mounting

capscrews (153J). Install into corresponding threaded

holes on seal sleeve. Torque capscrews to 20 inlbf

(2.25 Nm).

14. Lightly lubricate inner O-ring (153L) on carbon rotating

face using bearing grease identified in this manual. Take

care to keep seal face free from grease.

NOTICE

:

Use ONLY recommended grease.

Using petroleum

based grease or oil to lubricate seal O-rings WILL cause

seal O-ring damage and subsequent product leakage.

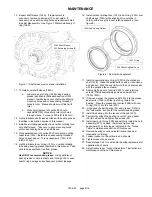

15. Install carbon rotating face and O-ring over shaft while

aligning drive notches with drive pins in seal rotating

assembly. (see figure 8)

16. Install a new stationary O-ring (153D) in the stationary

seat (153B). Clean the polished face with a clean tissue

and alcohol. Push the seat fully into the seal recess with

the polished face outward.

17. Apply small amount of Loctite #220 to seal retaining

screws. Install seal retaining screws and washers

(153Q, 153R).

18. If removed, press the grease seal(104A) into the grease

seal carrier (104b) with the lips facing toward the

bearing. Place the grease seal carrier (104B) with new

O-ring (104C) into the hub (20C).

19. Hand pack the ball bearing (24) with grease. Refer to

the "Lubrication" section for the recommended grease.

20. Install the bearing into the recess of the hub (20C).

21. Temporarily attach the bearing cover (27) and gasket

(26) to hub and hand tighten capscrews (28).

22. Install new hub O-ring (72B) and carefully install the hub

assembly (20C) on head. Install and tighten hub

capscrews (21A) torquing as indicated in the “Torque

Table”.

23. Remove the bearing cover and loosely install the bearing

locknut and lockwasher (24A, 24B). Snug the locknut on

the outboard head to help square the rotor with the head.

DO NOT overtighten the nut.

24. Set the pump upright.

25. Remove the outboard head and disc temporarily

attached earlier.

26. Complete assembly on the

OUTBOARD

side of the

pump as instructed for the inboard side in steps 10-24,

leaving the head capscrews loosely tightened.

27. Loosen the bearing locknut on the outboard head and

the rotate the shaft to test for binding or tight spots. If the

rotor does not turn freely, lightly tap the rims of the heads

with a soft faced mallet until the correct position is found.

Retighten all head capscrews, torquing to the

specifications indicated in the “Torque Table”.