701-D00 page 4/16

INSTALLATION

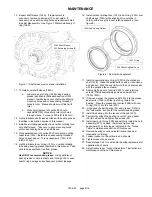

COUPLING ALIGNMENT

The pump must be directly coupled to a gear and/or driver

with a flexible coupling. Verify coupling alignment after

installation of new or rebuilt pumps. Both angular and parallel

coupling alignment MUST be maintained between the pump,

gear, motor, etc. in accordance with manufacturer’s

instructions. See Figure 3.

Figure 3 – Alignment Check

1. Parallel alignment: The use of a laser alignment tool or

dial indicator is preferred. If a laser alignment tool or dial

indicator is not available, use a straightedge. Turn both

shafts by hand, checking the reading through one

complete revolution. Maximum offset should be less

than .005" (0.127 mm).

2. Angular alignment: Insert a feeler gauge between the

coupling halves. Check the spacing at 90° increments

around the coupling (four check points). Maximum

variation should not exceed .005" (125 microns). Some

laser alignment tools will check angular alignment as

well.

3. Replace the coupling guards after setting alignment.

Operation without guards in place can

cause serious personal injury, major

property damage, or death.

Do not operate

without guard

in place

PUMP ROTATION

To determine pump rotation:

If the intake port is on the right, with the drive end of the shaft

pointing towards the observer, the pump is

right-hand

, or

CLOCKWISE rotation.

If the intake is on the left, with the drive end of the shaft

pointing towards the observer, the pump is

left-hand

, or

COUNTERCLOCKWISE rotation.

NOTICE:

Confirm correct pump rotation by checking the pump

rotation arrows respective to pump driver rotation.

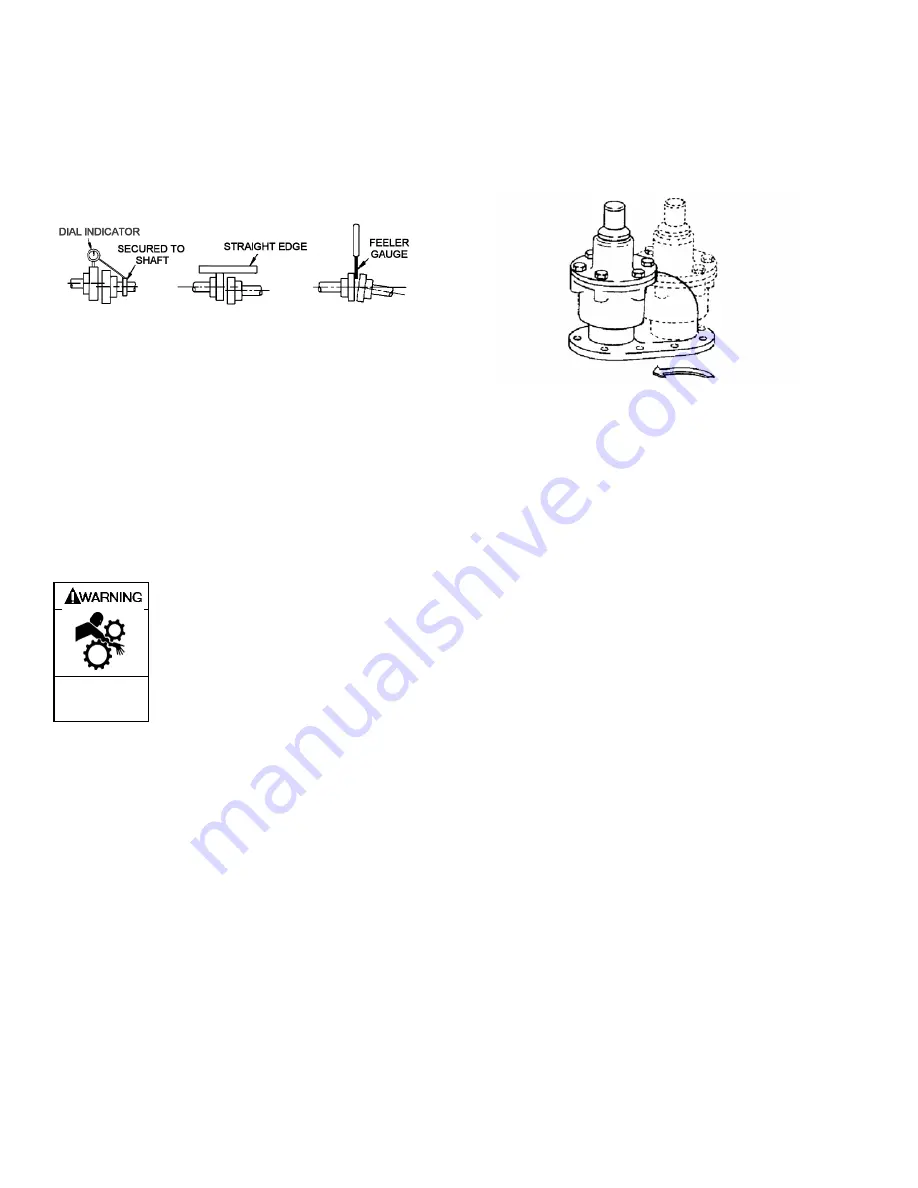

TO CHANGE PUMP ROTATION

To change pump rotation the pump must be disassembled

and the liner (41), vanes (14) and pump mounted relief valve

(if equipped) must be reversed. Refer to “Pump

Disassembly” and “Pump Assembly” sections of this manual

for parts removal and replacement instructions.

Figure 4 – Reversing the Relief Valve

CHECK VALVES

If a check valve is used, install it at the pump discharge. The

use of check valves or foot valves in the supply tank is not

recommended with self-priming, positive displacement

pumps.

If the possibility of liquid backflow exists when the pump is off,

a check valve in the pump discharge piping is recommended

because the pump can motor in the reverse rotation and

create undue stress on all attached components. Never start

a pump when it is rotating in the reverse rotation as the

added starting torque can damage the pump and related

equipment.

INTERNAL PUMP RELIEF VALVE AND

EXTERNAL BYPASS VALVE

NOTICE:

The optional pump internal relief valve is designed to

protect the pump from excessive pressure and must not

be used as a system pressure control valve.

For ALL liquefied gas applications, install an external bypass

valve, and any necessary piping, back to the tank. DO NOT

pipe the bypass valve back to the intake line. The setting on

the external bypass valve must be at least 25 psi (1.7 bar)

lower than the pump internal relief valve setting. The valve

and piping must be of adequate size to accommodate the full

flow from the pump when the discharge line is closed.