701-D00 page 7/16

MAINTENANCE

Failure to disconnect and lockout

electrical power before attempting

maintenance can cause shock, burns or

death

Hazardous voltage.

Can shock, burn or

cause death.

Failure to disconnect and lockout

electrical power or engine drive before

attempting maintenance can cause

shock, burns or death

Hazardous

machinery can

cause serious

personal injury.

Failure to relieve system pressure prior

to performing pump service or

maintenance can cause serious

personal injury or property damage.

Systems with meters will still be

pressurized even after the hose is

emptied

Hazardous pressure

can cause serious

personal injury or

property damage

Disconnecting fluid or pressure

containment components during pump

operation can cause serious personal

injury, death or major property damage

Hazardous pressure

can cause personal

injury or property

damage

If pumping hazardous or toxic fluids,

system must be flushed and

decontaminated, inside and out, prior

to performing service or maintenance

Hazardous or toxic

fluids can cause

serious injury.

Always use a lifting device capable of

supporting the full weight of the pump

assemblies.

Heavy assemblies

can cause personal

injury or porperty

damage.

NOTICE:

Maintenance shall be performed by qualified technicians

only, following the appropriate procedures and warnings

as presented in this manual.

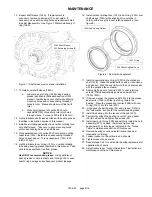

TORQUE TABLE

Capscrew Torque Values

Head Hub

Bearing

Cover

CRL8

178 lbs-ft.

(241 Nm)

50 lbs-ft.

(68 Nm)

50 lbs-ft.

(68 Nm)

SCHEDULED MAINTENANCE

STRAINERS

Strainers must be cleaned regularly to avoid pump starvation.

Schedule will depend upon the application and conditions.

LUBRICATION

NOTICE:

To avoid possible entanglement in moving parts do not

lubricate pump bearings, gear reducer or any other parts

while the pump is running

.

NOTICE:

If pumps are repainted in the field, ensure that the grease

relief fittings (76A) are functioning properly after

painting. Do NOT paint them closed. Remove any

excess paint from the fittings.

Ball bearings must be lubricated every three months at

minimum. More frequent lubrication may be required

depending on the application and operating conditions.

Recommended Grease:

Dow Corning

® -

MOLYKOTE 44

DuPont

® -

KRYTOX GPL 203

NOTICE

:

Use ONLY recommended grease.

Using petroleum based

grease or oil to lubricate seal O-rings WILL cause seal O-ring

damage and subsequent product leakage.

Greasing Procedure:

1. Remove the grease relief fittings (76A) from the bearing

covers (27 and 27A).

2. SLOWLY apply grease with a hand gun until grease

begins to escape from the grease relief fitting port.

Discard excess grease in accordance with proper codes

and regulations.

3. Replace the grease relief fittings (76A).

DO NOT overgrease pump bearings. While it is normal

for some grease to escape from the grease tell-tale hole

after lubrication, excessive grease can cause mechanical

seal failure. The tell-tale hole is located in the head or

hub between the bearing and the seal.

Lubricate the ball bearings, and hydraulic motor

couplings (if equipped), every three months at a

minimum