701-D00 page 8/16

MAINTENANCE

PUMP DISASSEMBLY

NOTICE:

Follow all hazard warnings and instructions provided in

the “Maintenance” section of this manual.

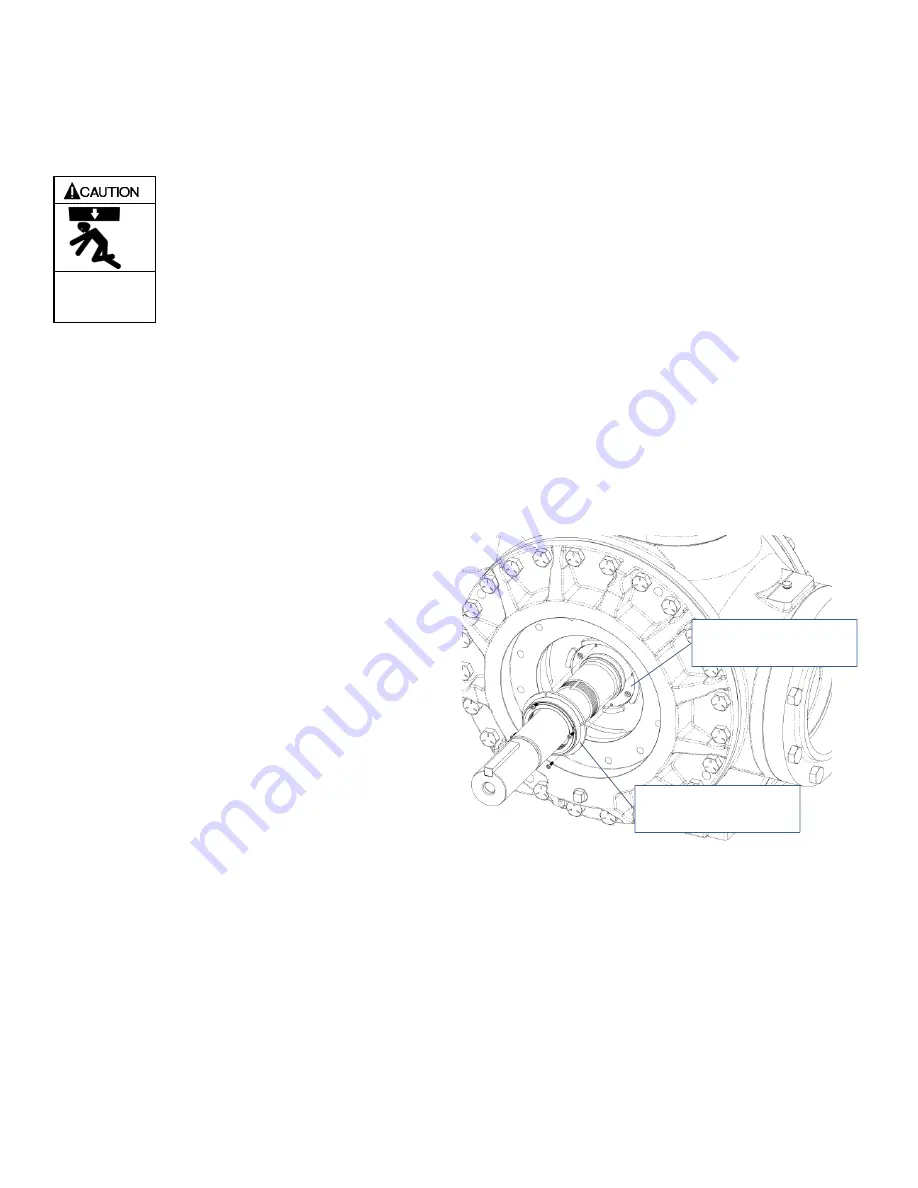

Always use a lifting device capable of

supporting the full weight of the pump

assemblies.

Heavy assemblies can

cause personal injury

or porperty damage.

NOTICE:

Use a hoist and appropriate sling or lifting lugs attached

to the baseplate to lift the entire pump assembly.

Eyebolts attached to the pump, gearbox, or motor must

be used to lift that particular component only.

NOTICE:

Use a hoist and eyebolts installed in the threaded holes

located in the heads, discs, rotor and casing to lift the

heavy pump parts.

Note: If a seal, bearings or vanes are to be replaced, the

pump may be left in the upright (shaft horizontal)

position. If the rotor-shaft or liner is to be removed, the

pump will have to be placed on its side (shaft vertical) for

some operations.

CRL8 pumps are equipped with hubs (20C) which allow

for bearing (24) and seal (153) replacement without

disturbing the pump head bolts (21). This document

covers both the “Seal or Bearing only”

Disassembly/Reassembly and “Complete pump”

Disassembly/Reassembly

FOR SEAL AND/OR BEARING ONLY

REPLACEMENT

1. Flush the pump per instructions in this manual. Drain

and relieve pressure from the pump and system as

required. A 3/4" drain plug (29) is fitted in each head.

2.

With the pump upright (shaft horizontal).

Clean the

pump shaft thoroughly, making sure the shaft is free of

nicks and burrs. This will prevent damage to the

mechanical seal when the inboard hub or head assembly

is removed.

3. Remove the inboard bearing cover capscrews (28) and

slide the inboard bearing cover (27A) and gasket (26) off

the shaft. Discard the bearing cover gasket.

4. Removing the locknuts and lockwashers (24A and 24B):

a. Bend up the engaged lockwasher tang and rotate

the locknut counterclockwise to remove it from the

shaft

b. Slide the lockwasher off the shaft. Inspect the

lockwasher for damage and replace as required.

5. Move to the outboard side of the pump and remove the

outboard bearing cover capscrews (28) and slide the

outboard bearing cover (27) and gasket (26) off the shaft.

Discard the bearing cover gasket.

6. Bend up the engaged lockwasher tang and tighten the

locknut (24A) on outboard end until shaft cannot be

rotated by hand. This will ensure proper rotor/shaft (13)

alignment during reassembly.

7. Return to the inboard side of the pump and wrap the

shaft threads with tape to ensure that grease seal (104A)

is not damaged upon hub removal.

8. Remove the capscrews (21A) from the inboard hub

(20C) and slide the hub assembly off the shaft. The

bearing (24), grease seal carrier assembly (104B, 104A

and 104C), stationary seat (153B) and stationary O-ring

(153D) of the mechanical seal will come off with the hub.

a. Pull the bearing (24) and grease seal carrier

assembly (104B, 104A and 104C) from the housing

in the hub.

b. If worn or damaged, remove the grease seal (104A)

from the carrier (104B).

c.

To remove the mechanical seal stationary seat

(153B), remove the seal retaining screws and

washers (153Q, 153R). Gently push the backside of

the stationary seat from the seal recess. Place a

cloth under the seal to avoid damage. Be careful not

to contact the polished face of the seal during

removal. Remove and discard mechanical seal

stationary O-ring.

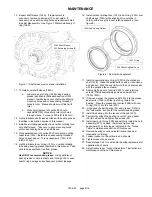

Figure 6 – Seal removal and Installation

9. Remove the remaining mechanical seal parts, including

the seal spring holder, springs, retaining ring, rotating O-

ring and face (153G, 153H, 153N, 153L, 153F) from the

shaft sleeve (154) by removing capscrews (153J).See

Figure 6. Take care to protect the carbon rotating face

from damage during disassembly. Remove and discard

rotating O-ring.

153G

Seal

Spring

Holder,

153J

Retaining

Screws

(4)

154A

Shaft

Sleeve,

155

Retaining

Screws

(2)