CB-9A-040 page 9

OPERATION

STARTUP PROCEDURE

1.

Start the compressor for a couple of second to verify proper rotation direction. See the section "Rotation".

2.

Start the compressor and check for oil pressure within 30 seconds. The pressure should register 25 psig

(172 kPa). Adjust if necessary (see "Lubrication").

If proper oil pressure is not present, stop the

compressor and correct the problem.

Operating the compressor with low oil pressure will cause severe

damage to the unit.

3.

Verify the suction and discharge pressures and ensure that all readings are within the expected ranges.

Operating limits listed in the "Compressor Data" section must not be exceeded

4.

Check for leakage from the piping and equipment.

5.

If the seals (packing) have just been replaced, the lower seal must be manually lubricated during the first

60 minutes of operation. See "Packing Lubrication" section. New compressors have had the packing

broken in at the factory.

6.

On newly rebuilt units, the valve holddown screws, valve cover plate bolts and cylinder head bolts should

all be retightened after 60 minutes running time. Also retighten all holddown bolts, flywheel bolts, etc. after

60 minutes running time.

MAINTENANCE

MAINTENANCE AND TROUBLESHOOTING MUST BE DONE BY AN INDIVIDUAL

EXPERIENCED WITH COMPRESSOR MAINTENANCE AND THE TYPE OF SYSTEM INVOLVED.

CAUTION: Before work is started on the compressor make sure all pressure is bled off on both the

suction and discharge.

NOTE:

When servicing the compressor, refer to the appropriate Parts Lists for detailed exploded views of the

compressor parts.

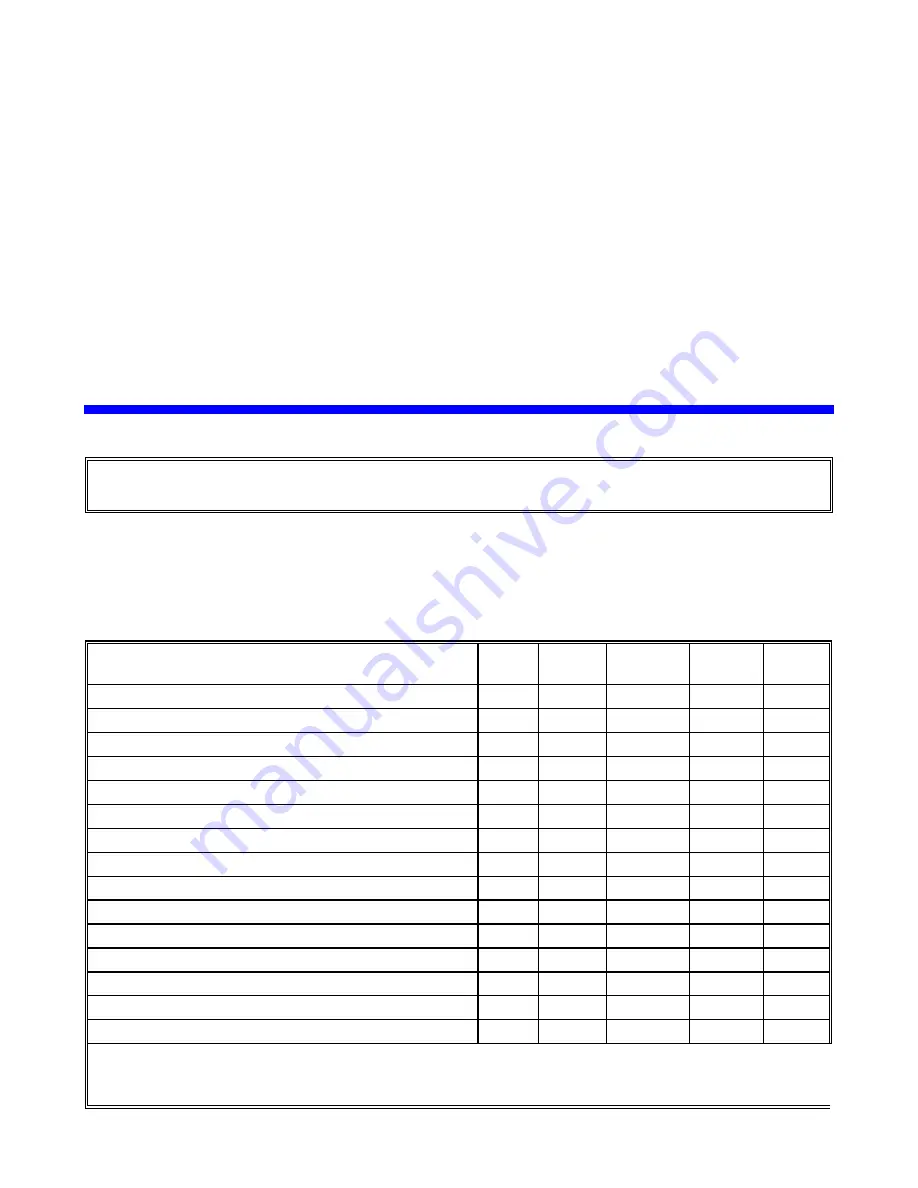

ROUTINE SERVICE SCHEDULE

Daily

Weekly

Monthly

6

Months

Yearly

Overall Visual Check

X

Check Crankcase Oil Pressure

X

Check Suction Pressure

X

Check Discharge Pressure

X

Drain Distance Piece

X

Drain Liquid From Accumulation Points

X

Clean Compressor Cooling Fins

X

Clean Compressor Intercooler Fins

X

Check Crankcase Oil Level *

X*

Check V-Belt Tension

X

Change Oil * (and Optional External Oil Filter)

X*

Check Inlet Filter/Strainer Element

X

Inspect Valves

X

Lubricate Motor Bearings per Manufacturers Suggestions

X

Inspect Motor Starter Contact Points

X

* Change oil every 1,000 hours of operation (2,000 hours with optional external oil filter), or every 6

months which ever occurs first. If the oil becomes unusually dirty, change oil and external filter as

often as needed to maintain clean oil.

Summary of Contents for HD172A

Page 23: ...CB 9A 040 page 23 NOTES...