COMPRESSOR ASSEMBLY

CB5A-021 page 16/24

c. After the lower set of packing is started over the

piston rod, make sure the oil deflector ring

(excluding LB602) is properly aligned (with the

flat side down) over the piston rod. Use the hole

in the side of the packing box to center the

deflector ring. Once the deflector ring is over the

rod, the packing box can be fully inserted.

d. Install the upper packing box O-ring on the end

of the packing box.

e. Place the packing box spacer ring over the

O-ring.

f. Install the packing box retainer ring, with new

nylon locking inserts, and tighten securely.

g. Repeat the above steps for the remaining

packing box.

6. Rotate the crankshaft by hand a few times, then

uniformly tighten the crosshead guide capscrews per

Table 7 - "Bolt Torque."

7. Break in new packing per the "Seal (Packing)

Replacement" section of this manual.

8.

CYLINDER ASSEMBLY

a. Install new O-rings in the bottom of the cylinder.

A small amount of grease may be used to hold

the O-rings in place during assembly.

b. Set the cylinder over the piston rods and against

the crosshead guide.

c. Install the cylinder capscrews. DO NOT tighten.

9.

PISTON RINGS

a. Place an expander in the top groove of the

piston. Place an expander in the second groove

with the break in this expander 180 degrees from

the break of the top expander. Place the third

expander in the bottom groove with its break in

the same position as the top expander.

b. Place piston rings in all three grooves of the

piston. Align the breaks in the piston rings

directly opposite the breaks in the corresponding

expanders.

10.

PISTONS

a. Rotate the flywheel by hand to bring one piston

rod to top dead center of the cylinder assembly.

b. Set the thrust washer and one shim on the

shoulder of the piston rod.

c. With light pressure, squeeze the piston rings

inward while threading the piston clockwise onto

the rod. Tighten with the 3" adjustable spanner

wrench.

d. Follow this same procedure for the second

piston.

e. Rotate the crankshaft by hand a number of times

to verify that the pistons are centered in the

cylinder bores. Adjust the cylinder so that the

pistons DO NOT touch the cylinder walls.

f. Using an alternating pattern, torque the cylinder

capscrews per Table 7 - "Bolt Torque."

11.

PISTON CLEARANCE

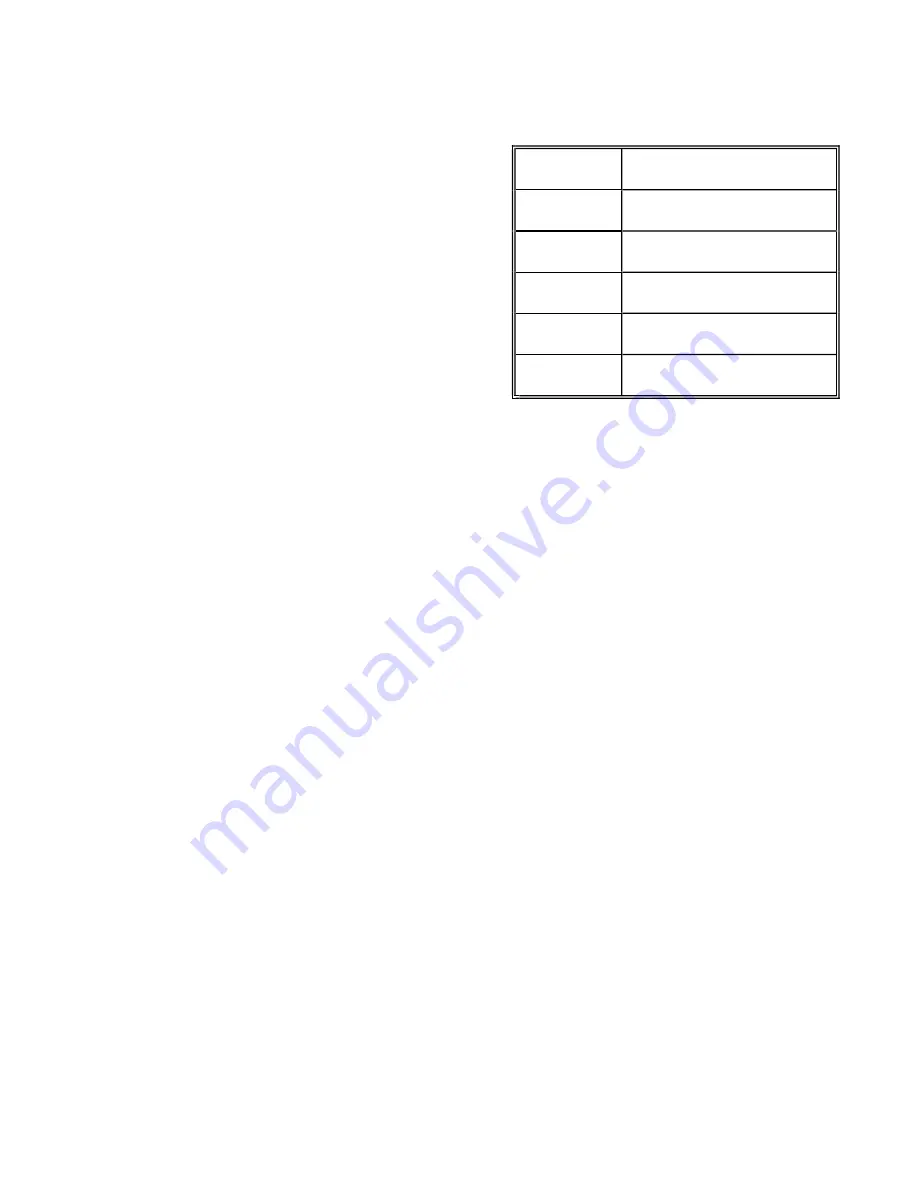

a. Rotate the flywheel by hand to bring one piston

to the top.

b. Measure the distance from the top of the piston

to the top of the cylinder.

LB161B

.010" to .025"

(.254 to .635 mm

LB162B

.015" to .030"

(.381 to .762 mm)

LB361B

.020" to .035"

(.508 to .889 mm)

LB362C

.025" to .040"

(.635 to 1.016 mm)

LB601B

.020" to .035"

(.508 to .889 mm)

LB602C

LB602B

.030" to .045"

(.762 to 1.143 mm)

Table 11 - Piston Clearance

c. If necessary, remove the piston and add or

subtract shims accordingly.

d. Install new nylon locking inserts in the piston

retainer nuts.

e. Thread the piston nut onto the piston rod and

tighten securely with the spanner wrench.

f. Follow this same procedure for the second

piston.

12.

CYLINDER HEAD ASSEMBLY

If the valve assemblies have been removed from the

cylinder head, refer to the "Valve Replacement"

section of this manual.

a. Place the cylinder head O-rings in the grooves

located on top of the cylinder.

b. Place the cylinder head assembly on top of the

cylinder.

c. Hand tighten the outer capscrews and center

capscrews into the cylinder head.

d. Gaskets MUST be used on the center

capscrews of the LB161 and LB162 models.

e. Uniformly torque the cylinder head capscrews

per Table 7 - "Bolt Torque."

13. Rotate the compressor by hand to verify that it turns

freely. Ensure that the pistons are not hitting the

cylinder head assembly.

14. Follow all procedures listed in the "Pre-Startup

Check List" and "Startup Procedure" sections of this

manual.

15. Start the compressor and bring to normal operating

temperature. Stop the compressor, allow it to cool

and retorque the valve hold down screws per Table

7 -"Bolt Torque."