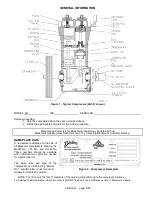

GENERAL INFORMATION

CB5A-021 page 4/24

An 11 character "I.D. No." identifies the construction of the compressor.

B

A

B

A

C

1

T

A

4

C

0

VALVES

Code Fields

Steel, w/ Liquid Relief

BA

1 & 2

O-RINGS

Field 3

Buna-N

B

GASKETS

Field 4

Aluminum

A

PISTON RINGS

Field 5

Carbon Filled PTFE

C

SEAL (PACKING) ORIENTATION

Field 6

All Lips up

1

SEAL MATERIAL

Field 7

PTFE

T

CYLINDER & HEAD

Field 8

Ductile Iron

A

GGG40.3 Ductile Iron

D

PISTON RODS

Field 9

Black Surface Steel

4

CRANKSHAFT & OIL FILTER

Field 10

No Oil Filter

A

Extended Crankshaft / No Oil Filter

B

Spin-on Oil Filter (std)

C

Ext. Crank / Oil Filter

D

FLYWHEEL *

Field 11

Standard Flywheel

0

No Flywheel

N

* Models Configured prior to 11/01/2017 used an “A” in this position to indicate standard selections.

Note: A 'Z' in any field indicates a non-standard option. No model is available with all shown options.

Table 2 - ID Number Key

Table 3 - Year of Manufacture *

Serial Number: 6 digits and a suffix letter indicating the year of manufacture.

Suffix

P

Q

R

S

T

U

V

W

X

Y

Z

Year

1994

1995

1996

1997

1998

1999

2000

2001

2002

2003

2004

* Starting in 2005, the suffix letter is no longer used; the year & month of construction is indicated on the nameplate

MAXIMIZING COMPRESSOR LIFE

Life of critical compressor components such as piston

rings, valves and packing will vary considerably with

each application, installation, and operating procedures.

Premature failure of wear parts can often be attributed to

one of the following causes:

Excessive Temperatures

Primary causes are:

Operating at pressures other than those originally

specified.

Handling a different gas than originally specified.

Clogged strainer or filter elements.

Line sizes too small, or other flow restrictions.

Excessive ambient temperature or suction gas

temperature.

Valve problems. (See Foreign Material.)

Badly worn piston rings. (See Foreign Material.)

Lower operating temperatures will increase valve and

piston ring life significantly.

Extreme temperatures caused by

abnormally high discharge pressure or

valve problems can be a source of

ignition in explosive atmospheres

causing severe personal injury or death.

Hazardous gases

can cause property

damage, personal

injury or death

Foreign Material

Solid particles in the gas stream will:

Rapidly wear the piston rings and score the cylinder

wall.

Destroy the rod packing causing excessive leakage

and score the piston rods.

Lodge in the valves causing loss of capacity and

broken valve plates and springs.

Liquid in the gas stream will:

Cause broken valve plates and springs.

Destroy the compressor if present in sufficient