501-A00 Page 8/12

MAINTENANCE:

PARTS REPLACEMENT

1. If any of the O-rings have been removed or disturbed

during disassembly, they must be replaced with new O-

rings.

2. Excessive or continuous leakage from the tell-tale hole in

the bearing cover may be an indication of a damaged

mechanical seal. If a mechanical seal has been leaking,

it is recommended the entire seal be replaced. Refer to

"General Pump Troubleshooting" for possible causes of

seal leakage.

PUMP ASSEMBLY

Before reassembling the pump, inspect all component parts

for wear or damage, and replace as required. Wash out the

bearing/seal recess of the head and cylinder and remove

any burrs or nicks from the rotor and shaft.

1. Position the pump cylinder (12) with the bearing side

up.

2. Apply a small amount of quality O-ring lubricant in the

seal and bearing recess of the cylinder to facilitate

mechanical seal (153) installation.

3. Insert the seal jacket assembly (153A) into the seal

recess of the cylinder with the drive tangs of the jacket

inward.

4. With the polished face outward, align the notches of the

rotating seal face with the jacket, and install the seal

face (153F) and O-ring (153G) into the jacket assembly.

After installation, clean the seal face with a clean tissue

and alcohol.

5. Clean the polished face of the stationary seat (153B)

with a clean tissue and alcohol.

6. Install new O-ring (153D) onto stationary seat (153B).

7. Align the notch in stationary seat (153B) with the anti-

rotation pin in the cylinder (12) and insert it into the seal

recess with the polished face inward to mate with the

rotating face.

8. Hand pack the ball bearing (24) with grease. Refer to

"Lubrication" in the Pump Maintenance Section for the

recommended grease.

9. Install the bearing (24) into the cylinder recess. The

bearing balls should face outward, with the grease

shield inward. Ensure that the bearing (24) is fully and

squarely seated against the mechanical seal (153).

10. Keep the bearing (24) from falling out of the cylinder

(12) by securing with one of the bearing cover

capscrews (28) and a washer that will catch the outer

ring of the bearing when tightened.

11. Turn the pump cylinder (12) over with the INTAKE port

and relief valve to the

right

.

12. The models described in this IOM are Right Hand

Rotation only. A Right-Hand rotation pump will have the

drive end of the shaft (long end) protruding through the

cylinder (12) with the bearing cover on the head.

13. Apply a light coating of quality O-ring lubricant to the

shaft end to be inserted into the cylinder.

14. Insert the shaft into the cylinder (12). Carefully slide the

shaft through the installed mechanical seal (153) and

bearing. Align the notch in the rotor with the drive tang

on the seal jacket of the mechanical seal. Rotate the

shaft to ensure the drive tangs of the mechanical seal

are engaged in the notches in the rotor.

15. Install lockwasher (24B) on the shaft protruding through

the bearing in the cylinder with the tangs outward. Ensure

the inner tang “A” of the lockwasher is engaged in the slot

in shaft threads. Bend it slightly, if necessary. (See Figure

8.)

16. Install locknut (24A) onto threads of shaft with the tapered

end inward.

17. Tighten the locknut (24A) with a spanner wrench to pull the

rotor flat against the back wall of the cylinder. DO NOT

overtighten the locknut and bend or shear the inner tang.

Adjustment to the locknuts will be made after the head is

installed.

18. Insert the vanes (14) into the slots in the rotor, ensuring

that the relief groove is facing toward the direction of

rotation. See Figure 6

19. Apply a light coating of quality O-ring lubricant in the seal

and bearing recess of the head (20) to facilitate

mechanical seal (153) installation.

20. Insert the seal jacket assembly (153A) into the seal recess

of the head with the drive tangs of the jacket inward.

21. With the polished face outward, align the notches of the

rotating seal face with the jacket, and install the seal face

(153F) and O-ring (53G) into the jacket assembly.

22. Clean the polished face of the stationary seat (153B) with

a clean tissue and alcohol.

23. Install new O-ring (153D) onto stationary seat (153B).

24. Align the notch in stationary seat (153B) with the anti-

rotation pin in the head (20). Insert it into the seal recess

with the polished face inward to mate with the rotating

face.

25. Hand pack the ball bearing (24) with grease. Refer to

"Lubrication" in the Pump Maintenance Section for the

recommended grease.

26. Install the bearing (24) into the head recess. The bearing

balls should face outward, with the grease shield inward.

Ensure that the bearing (24) is fully and squarely seated

against the mechanical seal (153).

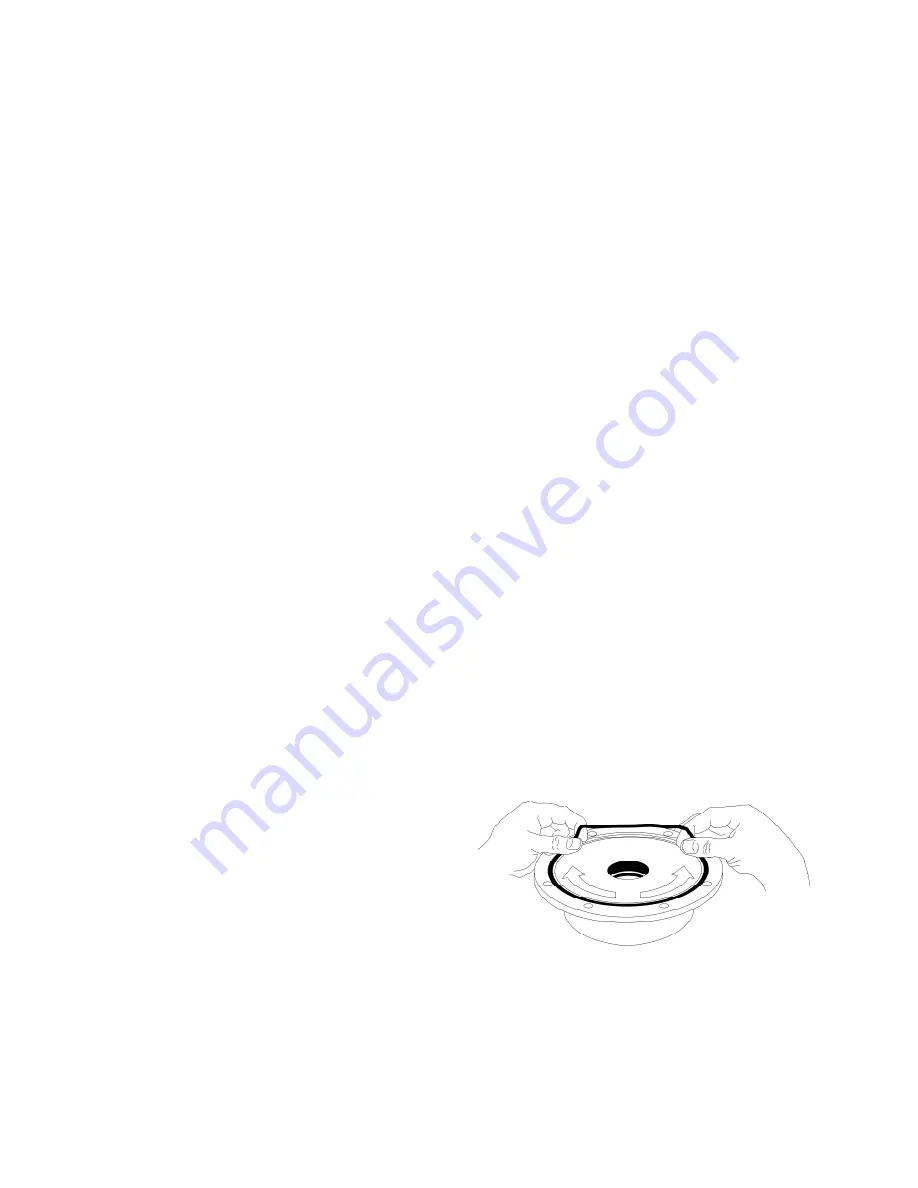

27. Apply a small amount of quality O-ring lubricant to the O-

ring groove on the inside face of the head and install a

new head O-ring (72) in the groove by laying the O-ring flat

and starting in on one side of the groove, stretching ahead

with the fingers, as shown in Figure 7.

Figure 7 Head O-ring Installation