103-A00 page 11/12

PUMP TROUBLESHOOTING

….Continued

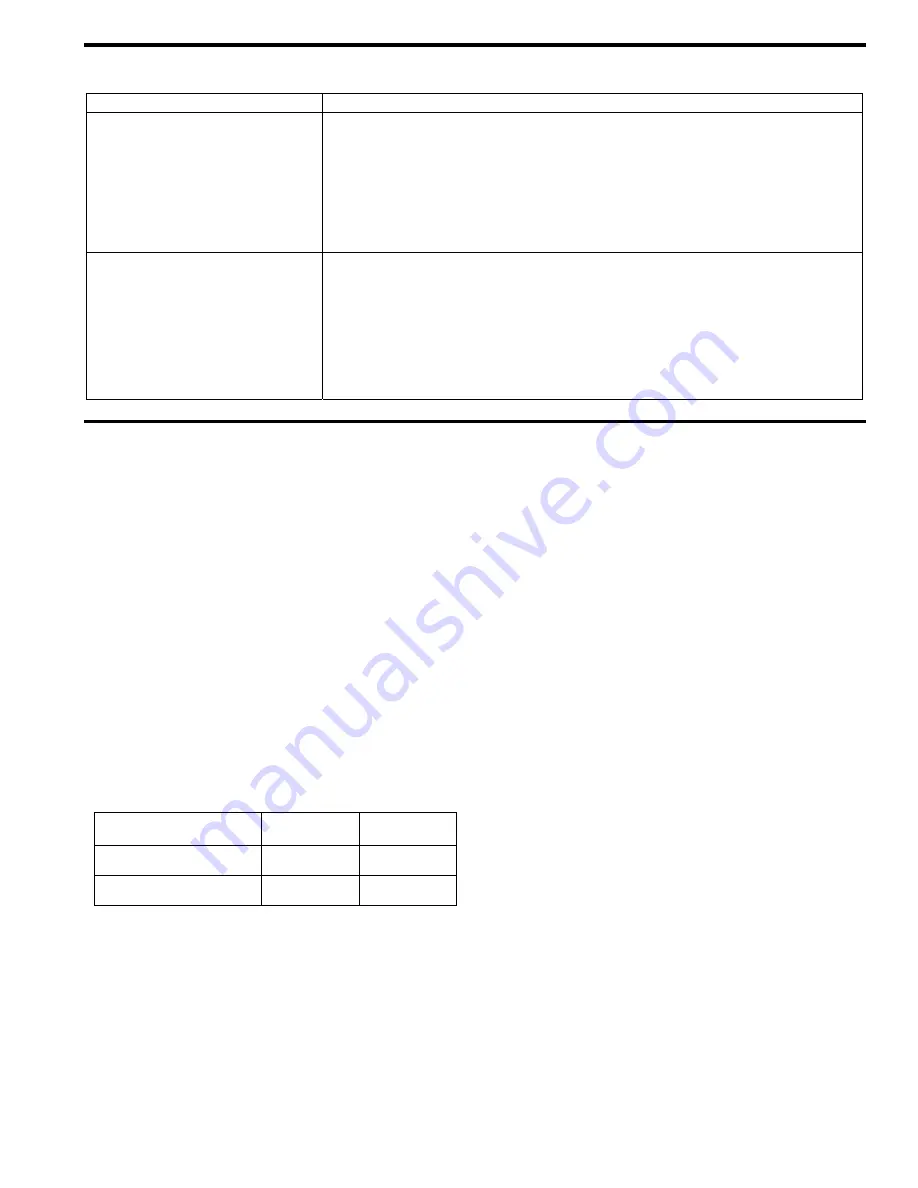

SYMPTOM

PROBABLE CAUSE

Overload on Motor

1. Horsepower of motor not sufficient for application.

2. Improper wire size or wiring.

3. Misalignment.

4. Excessive viscosity, pressure or speed.

5. Faulty or worn sleeve bearings (bushings).

6. Rotor rubbing into head.

7. Excessively tight packing (see “Packing Adjustment”).

8. Unevenly tightened stud nuts, causing shaft interference with packing follower.

Mechanical Seal Leakage

(if equipped)

1. Seal Rings/O-rings not compatible with the liquids pumped.

2. Seal Rings/O-rings nicked, cut or twisted.

3. Shaft at seal area damaged, worn or dirty.

4. Excessive cavitation.

5. Mechanical seal faces cracked, scratched, pitted or dirty.

6. Pump sleeve bearings worn excessively.

NOTE: Consult commercial mechanical seal manufacturer for more information

on mechanical seal troubleshooting.

AFFF SERVICE PUMPS – Special Notes

NOTICE:

Design and materials of construction should be suitable

for use with the type of foam concentrate to minimize

corrosion, foaming, or sticking

NOTICE:

Blackmer NP pumps are not approved for use in systems

where automatic system pressure balance exceeds 200

psi, 13.79 bar (175 psi, 12.07 bar for the NP4, NPH4).

DESCRIPTION

AFFF pumps were previously listed as FFNP models. They

are now NP pumps with specific options:

Duravanes (1.5” – 3”)

Laminate Vanes (4”)

Lip Seal

Corrosion Resistant RV

Stainless Steel 200 psi spring

Buna-N O-Rings

Casing Drain

TABLE 1 – TECHNICAL DATA

1.5”, 2”,

2.5”, 3”

4”

Maximum Differential

Pressure

200 psi

(13.79 Bar)

175 psi

(12.07 Bar)

Maximum Working

Pressure

220 psi

(15.17 Bar)

195 psi

(13.44 Bar)

LOCATION AND PIPING

NOTICE:

A system pressure control device, in addition to the

pump relief valve, is required.

OPERATION

NOTICE:

The pump must be tested, for a ten minute period, every

30 days. During this activity, the pump discharge must

be recirculated through a bypass system. Do not

operate the pump against a closed discharge.

An electrical time clock is recommended to record

elapsed operating time. Refer to the ‘Scheduled

Maintenance - Pump’ section.

PUMP RELIEF VALVE

NOTICE:

The pump’s internal relief valve is designed to protect

only the pump from excessive pressure and must not be

used as a system pressure relief valve. Foam system

pressure must be controlled by a separate bypass

pressure control valve which returns bypassed fluid to

the foam storage tank.

SCHEDULED MAINTENANCE - PUMP

1. Pump MUST be disassembled and checked after each

ten hours of system trial operation, or five years,

whichever occurs sooner. The heads (20 & 23), cylinder

(12), bushing (24) and vanes (14) MUST be inspected

for wear. Replacement of worn parts is required.

Inspect the rotor and shaft for wear or corrosion. If rotor

& shaft indicates wear, scaling, flaking rust particles or

cracking, replacement is required.

2. If during operation of the system the contents of the

foam concentrate tank has been depleted OR there is

reason to believe the pump has run dry, the pump MUST

be completely disassembled and carefully inspected for

damage or wear. The heads (20 & 23), cylinder (12),

bushing (24) and vanes (14) MUST be inspected for

wear. Replacement of worn parts is required. Inspect

the rotor and shaft for wear or corrosion. If rotor & shaft

indicates wear, scaling, flaking rust particles or cracking,

replacement is required.