103-A00 page 4/12

INSTALLATION

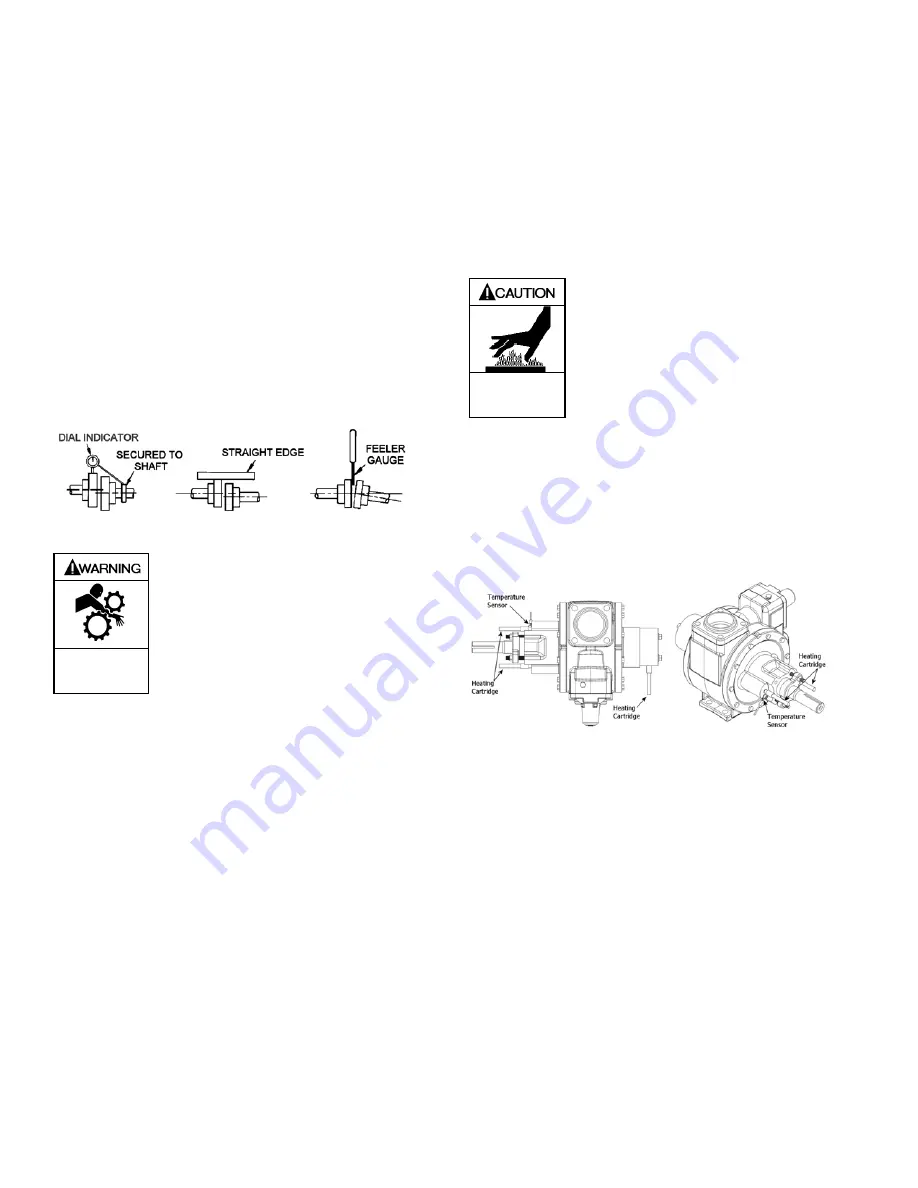

COUPLING ALIGNMENT

The pump must be directly coupled to a gear and/or driver

with a flexible coupling. Verify coupling alignment after

installation of new or rebuilt pumps. Both angular and parallel

coupling alignment MUST be maintained between the pump,

gear, motor, etc. in accordance with manufacturer’s

instructions. See Figure 3.

1. Parallel alignment: The use of a laser alignment tool or

dial indicator is preferred. If a laser alignment tool or dial

indicator is not available, use a straightedge. Turn both

shafts by hand, checking the reading through one

complete revolution. Maximum offset should be less than

.005" (.127 mm).

2. Angular alignment: Insert a feeler gauge between the

coupling halves. Check the spacing at 90° increments

around the coupling (four checkpoints). Maximum

variation should not exceed .005" (.127 mm). Some laser

alignment tools will check angular alignment as well.

3. Replace the coupling guards after setting alignment.

Figure 3 – Alignment Check

Operation without guards in place can

cause serious personal injury, major

property damage, or death.

Do not operate

without guard

in place

PUMP ROTATION

A right-hand pump rotates clockwise with the intake on the

right side, when viewed from the driven end.

A left-hand pump rotates counterclockwise with the intake on

the left side, when viewed from the driven end.

NOTICE:

Confirm correct pump rotation by checking the pump

rotation arrows respective to pump driver rotation.

TO CHANGE PUMP ROTATION

To reverse rotation, the pump must be disassembled then

reassembled with the shaft on the opposite side of the pump.

See the ‘Maintenance’ section for instructions.

HEATING HEADS / JACKETS

NOTICE:

Maximum recommended heating jacket steam pressure

is 150 PSI (10.3 bar).

Jacketed heads are recommended for heating highly

viscous liquids, or to “thaw out” liquids that have congealed

in the pumping chamber and packing area.

Hot oil or steam can be circulated through the jacketed

heads by 3/4” NPT connections (3/8” NPT on 1.5” models)

above and below the shaft.

Pumps fitted with heating devices have

hot surfaces that can cause serious

personal injury.

Extreme heat can

cause injury or

property damage.

HEATING HEADS / ELECTRIC

The NP2.5, 3 and 4” pumps may be fitted with heads for

electric heating. The inboard head has two 12.5mm bore

(85 mm deep) Heating Cartridge ports and two M6 x 1.0

(12 mm deep) Temperature Sensor ports. The outboard

bearing cover has one 12.5mm bore (85 mm deep) Heating

Cartridge port. Follow the manufacturer’s instructions when

installing the heating system.

Figure 3a – Heads for Electric Heating

CHECK VALVES

The use of check valves or foot valves in the supply tank is

not recommended with self-priming, positive displacement

pumps.

If the possibility of liquid backflow exists when the pump is

off, a check valve in the pump discharge piping is

recommended because the pump can motor in the reverse

rotation and create undue stress on all attached

components. Never start a pump when it is rotating in the

reverse rotation as the added starting torque can damage

the pump and related equipment.