103-A00 page 9/12

MAINTENANCE

(1.5” and 2” models have only four vanes)

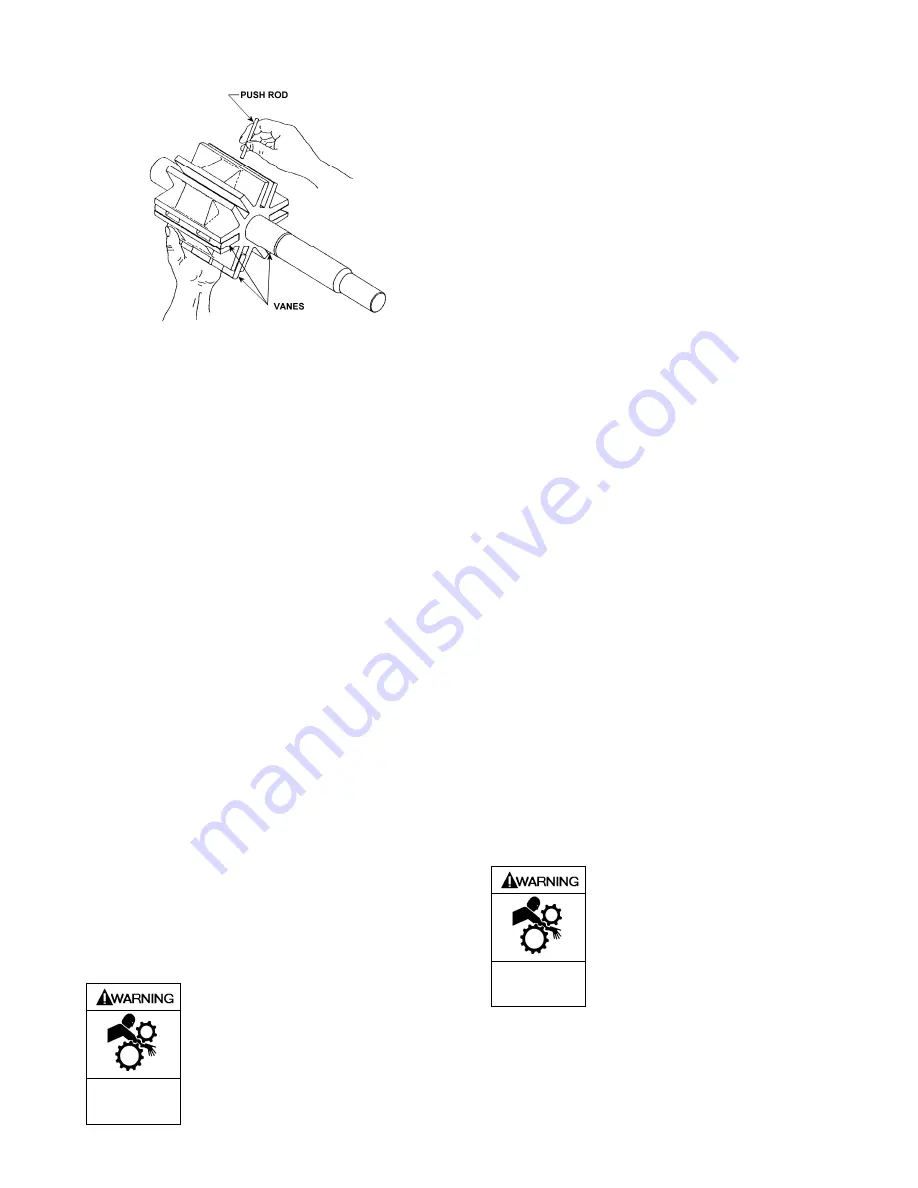

Figure 6 – Push Rod Installation

8. Remove the vanes and push rods from the rotor and

shaft assembly and inspect for wear or damage.

a. Insert the vanes (14) into the bottom rotor slots with

the rounded edges facing outward, and the relief

grooves facing in the direction of rotation. (Refer to

Figure 4.)

b. Hold the vanes in place while inserting the push rods

(77) from the top, as shown in Figure 6.

c. While holding the vanes in place, carefully slide the

non-driven end (shorter end) of the pump shaft into

the open end of the pump cylinder and into the

installed outboard head.

d. Install the remaining vanes into the top slots of the

rotor with the relief grooves facing in the direction of

rotation and the rounded edges outward.

9. Install the inboard head (20) as instructed previously in

steps 3 through 6.

10.

PACKING AND PACKING FOLLOWER

When necessary to re-pack, use a full set of new

packing rings. Packing is furnished in sets with the

correct number of rings. Never add new rings to an old

set of packing.

a. Insert the pack washer (58) into the stuffing box of

the inboard head (20).

b. Insert each of the packing rings (19) separately into

the stuffing box, staggering the split joints 180

degrees, so that they are not overlapping or near the

joint of the preceding ring. Use the packing follower

to properly seat each ring after placement.

c. After all of the packing rings are in place, slide the

packing follower (75) against the packing. Install and

hand-tighten the stud nuts (18) evenly.

NOTE:

Adjustment to the packing follower should be

made after the running the pump for 10 to 15 minutes

(see "Packing Adjustment").

11.

PACKING ADJUSTMENT

It is important that the packing be properly adjusted to

prevent overheating.

Failure to stop the pump before

adjusting the shaft packing can cause

severe personal injury

Hazardous

machinery can

cause severe

personal injury.

a.

While the liquid is being pumped, check for leakage

from the stuffing box. If necessary,

STOP

the pump

and uniformly tighten the packing follower stud nuts

(18) 1/4

turn at a time to reduce leakage.

b. Restart the pump and check the stuffing box

temperature several minutes after each adjustment for

signs of overheating.

c. Repeat steps a and b until leakage is controlled, and

no excess heat develops.

d. Check the packing again after 20 to 30 minutes of

running the pump, and readjust, if necessary.

NOTE

: Some leakage is desirable to lubricate the packing,

but in some cases it is unacceptable, depending on the

application. A commercial mechanical seal should be used

for applications requiring minimal shaft leakage.

12.

OPTIONAL LIP SEAL ASSEMBLY

a. Insert the wave spring (152D) into the stuffing box of

the inboard head.

b. Lightly grease the inboard shaft to facilitate lip seal

installation. With the lip seal spring facing the pump,

slide the lip seal assembly (152) into the stuffing box,

against the wave spring.

c. Install the seal follower (75) against the lip seal

assembly. Install and tighten the follower capscrews

(16).

NOTE:

When installed properly, lip seals should require no

adjustment.

13.

COMMERCIAL MECHANICAL SEAL

On pumps equipped with a commercial mechanical seal,

refer to the separate literature accompanying the

mechanical seal for installation instructions.

14. RELIEF VALVE ASSEMBLY

a. Insert the valve (9) into the relief valve body (6) with

the fluted end inward.

b. Install the relief valve spring (8) and spring guide (7)

(and valve collar (9A) on the NP2.5) against the valve.

c. Attach a new relief valve gasket (10) and the valve

cover (4) on the relief valve body (6).

d. Screw the relief valve adjusting screw (2) into the valve

cover until it makes contact with the spring guide (7).

e. Install the relief valve cap (1) and gasket (88) after the

relief valve has been precisely adjusted.

NOTICE:

The relief valve setting MUST be tested and adjusted

more precisely before putting the pump into service.

Refer to "Relief Valve Setting and Adjustment"

15. Reinstall coupling, shaft key, and coupling guards.

Operation without guards in place can

cause serious personal injury, major

property damage, or death.

Do not operate

without guard in

place.

15. Refer to “Pre-Start Up Check List” and “Start Up

Procedures” sections of this manual prior to pump

operation.