111-B00 Page 10/16

MAINTENANCE:

PUMP ASSEMBLY

Before reassembling the pump, inspect all component

parts for wear or damage, and replace as required. Wash

out the bearing/seal recess of the head and remove any

burrs or nicks from the rotor and shaft.

Reassemble the BEARING Components first:

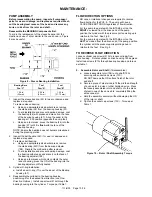

To aid in the replacement of the sleeve bearing (24) the

creation and use of a tool similar to the one shown in Figure

8 may be useful.

Figure 8 – Sleeve Bearing Installation

Bearing Bore

Dia. “C”

Tool

Dim “A”

Tool

Dim “B”

1.26 in.

(32mm)

2.05 in.

(52 mm)

1.25 in.

(31.75 mm)

1. Inspect the sleeve bearing (24) for wear or damage and

replace as required.

To replace sleeve bearing:

a. Using an appropriately sized arbor press, remove

the old bearing (24) from the bearing housing (57).

b. To aid installation and prevent bearing damage, coat

the bearing (24) with grease and place it on the face

of the bearing housing (57). Align the seam in the

bearing at 12:00 position (opposite the pump foot)

c.

Using an arbor press, press the bearing (24) into the

housing (57) until it is

flush

with the face of the

bearing housing.

NOTE: Ensure the bearing does not become misaligned

during the pressing motion

2. Inspect the ball bearing (24C) for wear or damage and

replace as required.

To replace ball bearing:

a. Using an appropriately sized arbor press, remove

the old bearing (24C) from the bearing adjuster

(188). Discard the old bearing after removal.

b. To aid installation and prevent bearing damage, coat

the bearing with grease and place it on the face of

the bearing adjuster (188)

c.

Using an arbor press which only contacts the outer

race of bearing, press the OD of the bearing into the

bearing adjuster until fully seated.

3. Cylinder O-ring installation

a. Install a new O-ring (71) over the dowel of the Bearing

housing (57).

4. Reassemble the cylinder to the bearing housing

positioning it for the desired flow direction (

see Flow

Direction Options

). Install cap screws (21A) through the

bearing housing into the cylinder. Torque per Table 1.

FLOW DIRECTION OPTIONS

NO vane or rotational changes are required to reverse

flow direction for the PV6, 8. The pump will have a

CLOCKWISE ROTATION regardless of flow direction.

For the pump to operate with the INTAKE port on the

RIGHT

as viewed from the driven end of the pump,

position the cylinder with the pressure ports pointing up in

relation to the feet. See Fig 4.

For the pump to operate with the INTAKE port on the

LEFT

as viewed from the driven end of the pump, position

the cylinder with the pressure ports pointing down in

relation to the feet. See Fig 5.

TO REVERSE FLOW DIRECTION

Loosen cylinder cap screws (21A) to loosen cylinder from

drive housing. Rotate cylinder on drive housing 180 degrees.

Install cap screws (21A) through bearing housing and torque

per table 1.

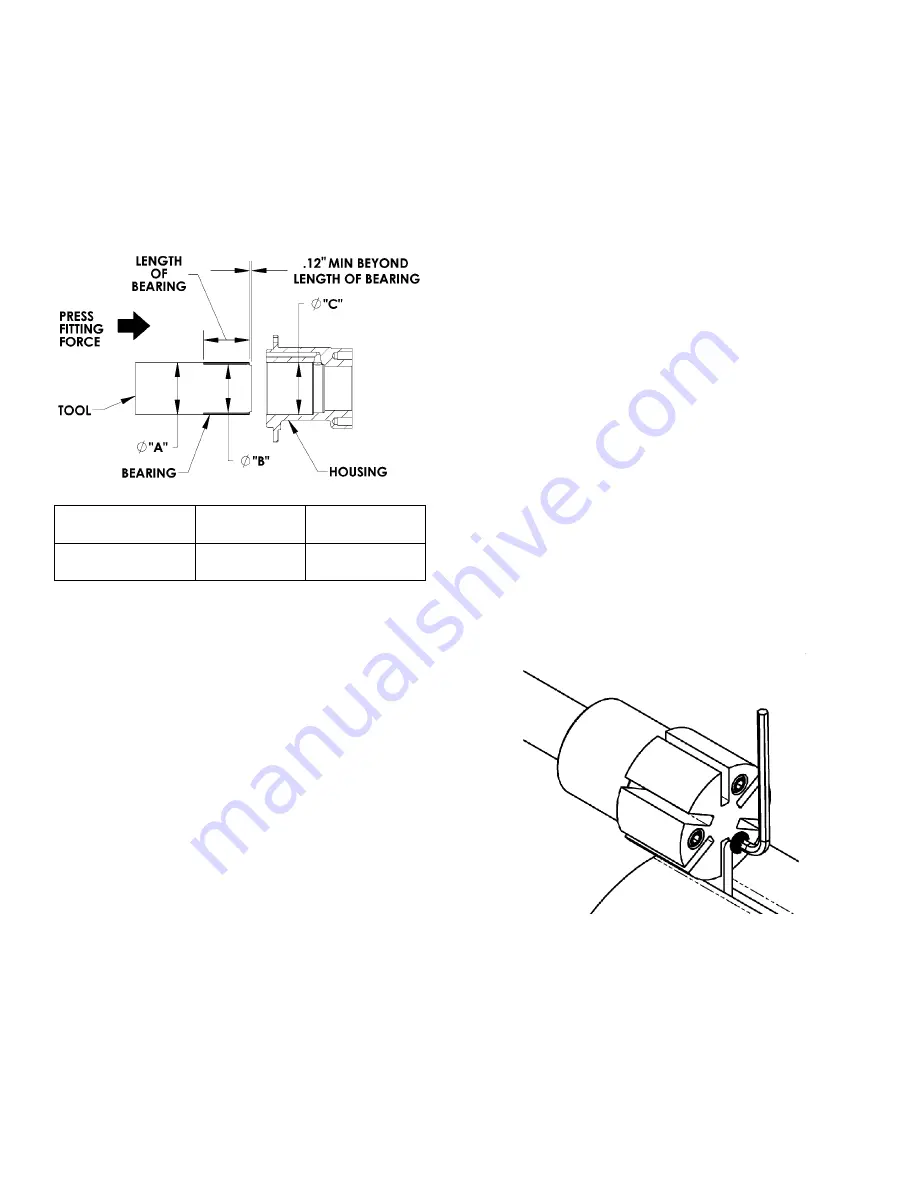

5. Assemble Rotor and Shaft

(if disassembled).

a. Loosely assemble rotor (13B) on to shaft (13A)

securing with socket cap screws (13C).

DO NOT damage the OD surface finish of the rotor

and shaft.

b. Secure a piece of steel sized to fit the width and length

of a vane slot in a vise or other holding device. Place

the loosely assembled rotor and shaft on to the piece

of steel in one of the vane slots; completely filling the

entire vane slot.

c. Hold the assembly securely without damaging the OD

of the rotor or shaft.

d. Tighten the socket cap screws (13C). Torque per

Table 1.

Figure 10 – Rotor / Shaft Assembly Torque

Summary of Contents for ProVane PV6B

Page 15: ...111 B00 Page 15 16 NOTES...