111-B00 Page 12/16

MAINTENANCE:

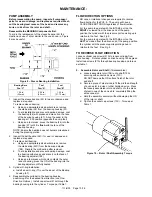

14. LOCKNUT ADJUSTMENT

It is important that the bearing locknut (24A) and lock

washer (24B) be installed and adjusted properly. Over

tightening the locknut can cause bearing failure or a

broken lock washer tang. A loose locknut will allow the

rotor to shift within the pump, causing wear.

See Figure 12.

Figure 12 – Locknut Assembly

a. On the end of the pump shaft, install a lock washer

(24B) with the tangs facing outward, followed by a

locknut (24A) with the tapered end inward. Ensure the

inner tang "A" of the lock washer is located in the slot

in the shaft threads, bending it slightly, if necessary.

b. Tighten the locknut to ensure that the bearing is

bottomed in the recess. DO NOT over tighten and

bend or shear the lock washer inner tang.

Bearing Adjustment

15. Turn the bearing adjuster counterclockwise, as viewed

from the driven end of the pump, until the shaft is snug

and no longer turns. Mark a line across the bearing

adjuster and drive housing.

16. Turn the bearing adjuster clockwise, as viewed from the

driven end of the pump the distance prescribed per table

2. Measurement to be taken on outside of drive housing.

Table 2

Pump size

Distance on OD of Drive Housing

PV 6,8

3/4” (19.05 mm)

17. Tighten the bearing adjuster lock setscrews and torque

per table 1.

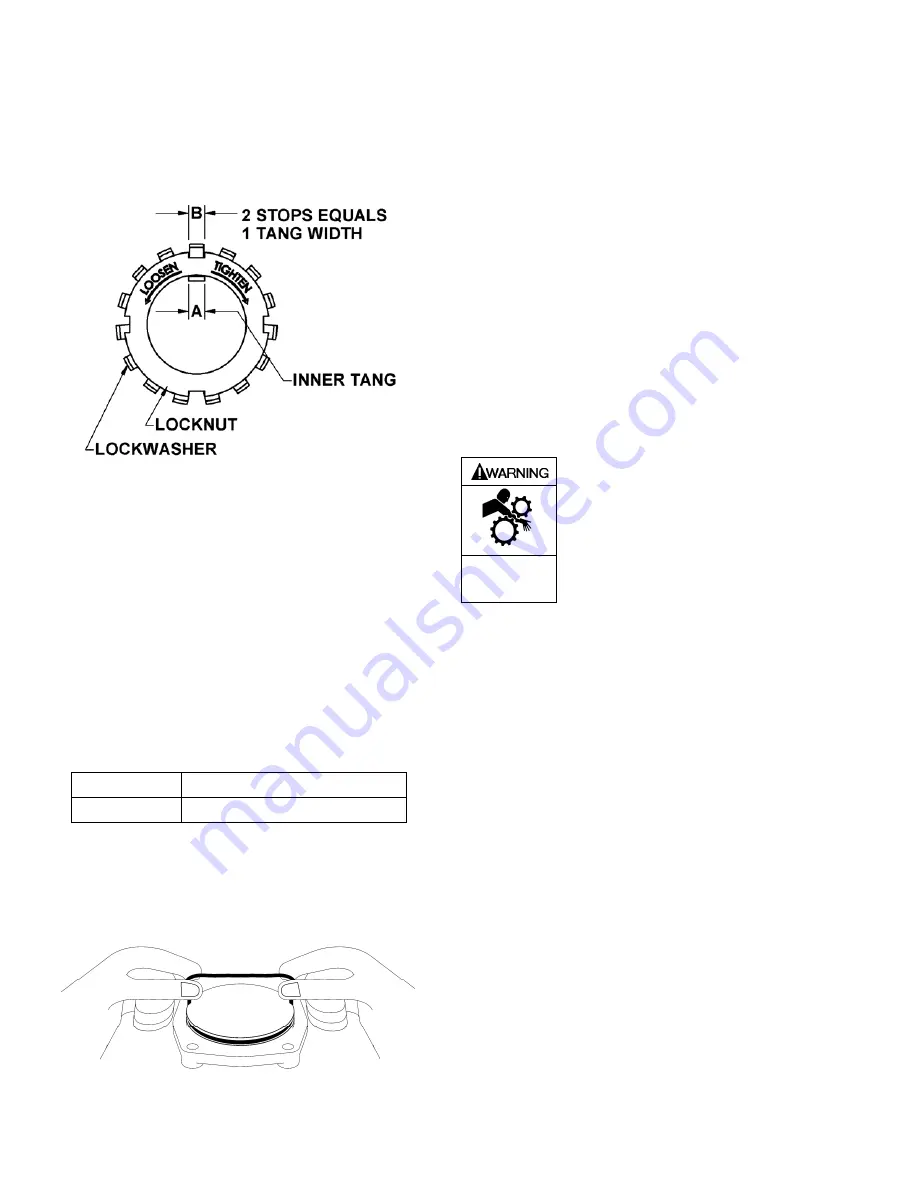

18. Install a new head O-ring (72) on the dowel of the head

as shown in Figure 13.

Figure 13 – Head O-ring Installation

19.

Carefully install the head (23) into the cylinder.

If pump

is equipped with internal relief valve, orient the relief

valve per instruction in PUMP RELIEF VALVE section

of this manual.

Install and tighten four head cap screws

(21A). Torque per table 1.

20. RELIEF VALVE ASSEMBLY

a. Insert the valve into the valve body with the fluted in

inward.

b. Install the relief valve spring onto valve and spring

guide onto spring.

c. Screw the adjusting screw into the valve cover until it

makes contact with the spring guide

d. Install the relief valve cap and O-ring after the relief

valve has been properly adjusted.

NOTICE:

The relief valve setting MUST be tested and adjusted

more precisely before putting the pump into service.

Refer to “Relief Valve Setting and Adjustment”.

21. Reinstall coupling, shaft key, and coupling guards.

Operation without guards in place can

cause serious personal injury, major

property damage, or death.

Do not operate

without guard

in place

22. Refer to “Pre-Start Up Check List” and “Start Up

Procedures” sections of this manual prior to restarting

pump operation.

Summary of Contents for ProVane PV6B

Page 15: ...111 B00 Page 15 16 NOTES...