111-B00 Page 8/16

MAINTENANCE:

Torque Table 1

Pump Size

PV6B, 8B

Head / Casing Cap Screws

in-lbs 42

N-m 4.75

Rotor Capscrews

in-lbs 34

N/m 3.84

Relief Valve Capscrews

in-lbs 15

N-m 20.3

Bearing Adjuster Set Screw

(189)

in-lbs 9.5

N-m 1.07

Suggested Tool List

Allen Wrenches: 7/64”, 2mm - 5mm

Combination Wrenches: 10mm - 12mm, 23mm

Pliers: Standard & Long Nose

Spanner Wrench

Strap Wrench

Ball Peen Hammer: 8oz.

Ratchet & Socket Set: 10mm - 12mm, 23mm

Mallet: shot loaded rubber

Screwdrivers: (2), slot type

SCHEDULED MAINTENANCE

LUBRICATION

The Blackmer ProVane pumps are equipped with

ball bearings that require no additional lubrication.

STRAINERS

Strainers must be cleaned regularly to avoid pump starvation.

Schedule will depend upon the application and conditions.

VANE REPLACEMENT

NOTICE:

Maintenance shall be performed by qualified technicians

following the appropriate procedures and warnings as

presented in this manual.

See the table on page 1 of this manual to determine what

model you have.

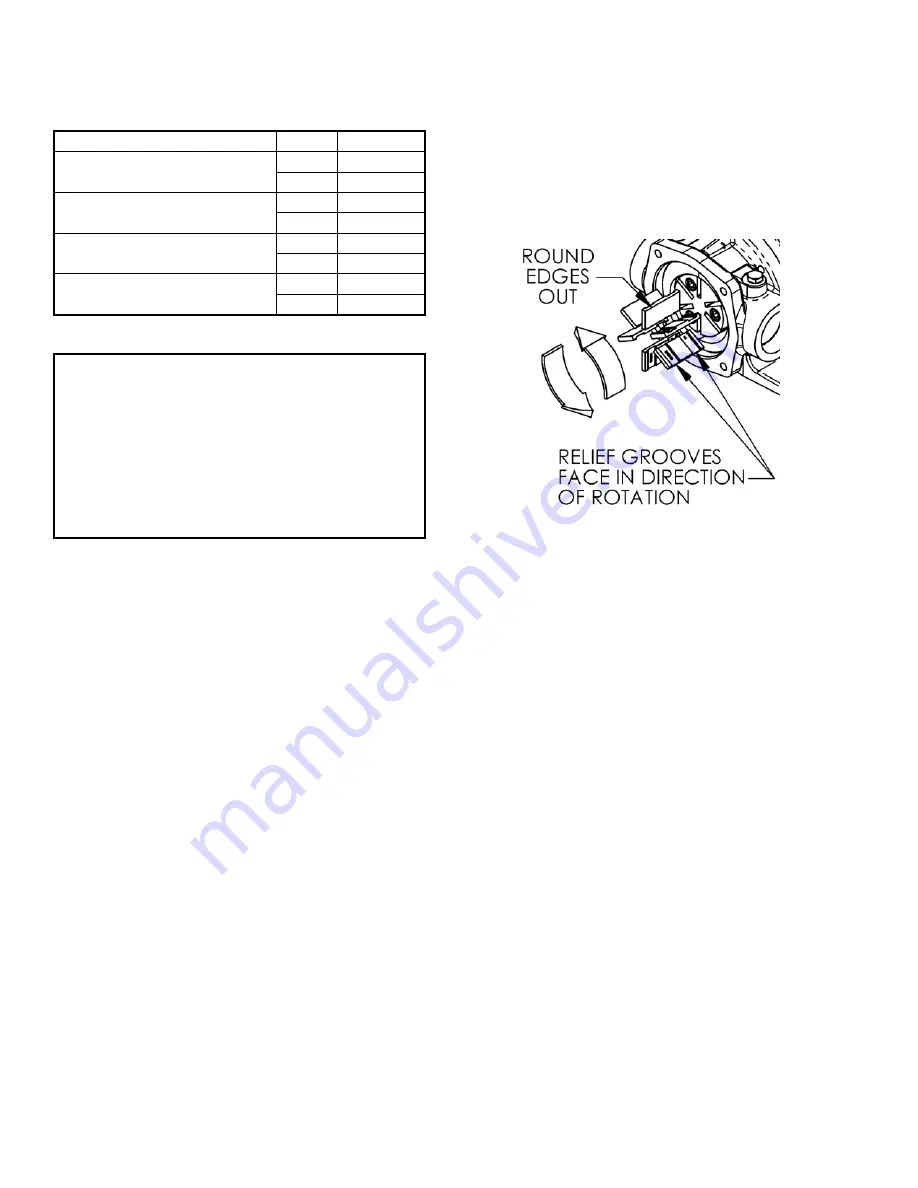

Figure 6 – Vane Replacement

1. Flush the pump per instructions in this manual. Drain and

relieve pressure from the pump and system as required.

2. Remove the head cap screws (21). Gently pry the head

away from the casing using two screwdrivers. The head

O-ring should come off with the head assembly.

3. Turn the shaft by hand until a worn vane comes to the top

(12 o'clock) position of the rotor. Remove the vane.

4. Install a new vane, ensuring that the rounded edge is UP,

and the relief grooves are facing towards the direction of

rotation. See Figure 6.

5. Repeat steps 3 and 4 until all vanes have been replaced.

This method of vane installation ensures the push rods do

not fall out of their rotor slots.

6. Carefully install the head (23) into the casing or cylinder.

Install and tighten four head cap screws (21). If equipped

with optional relief valve, to insure proper orientation see

Figures 4 and 5 in

Optional Pump Relief Valve

section

Torque per Table 1 shown at the beginning of the

maintenance section.

Summary of Contents for ProVane PV6B

Page 15: ...111 B00 Page 15 16 NOTES...