104-A00 Page 10/16

MAINTENANCE

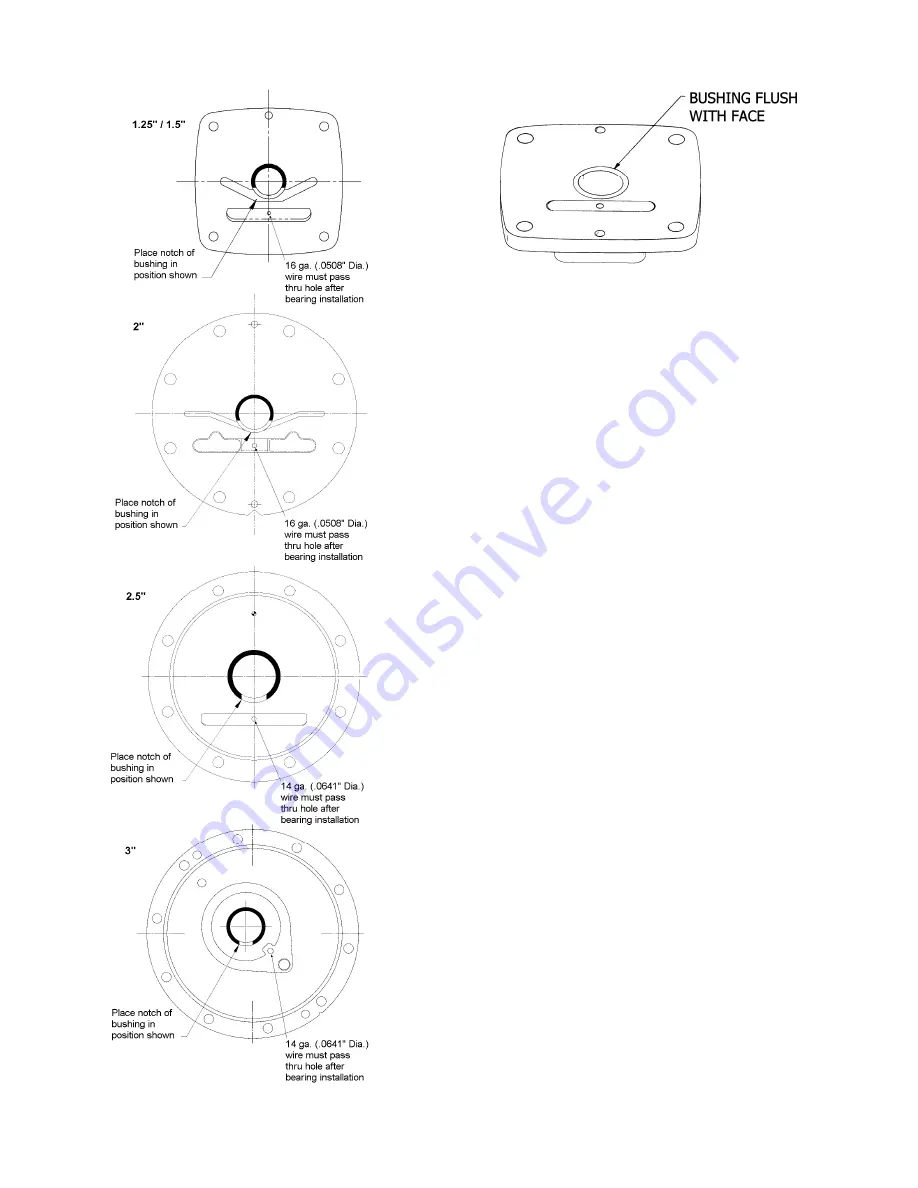

Figure 7a – Sleeve Bearing Alignment

Figure 7b – Sleeve Bearing Installation

4.

SLEEVE BEARINGS (Bushings)

If the sleeve bearing has been removed from the head, a new

bearing must be installed.

a. To aid installation, heat the head in an oven at

200°F (93°C) before installing the bearing.

b. Coat the new bearing with a quality grade of bearing

grease, and place it on the inside face of the head

with the notched end UP.

Align the notch in the

bearing with the groove in the head

. See figure

7a.

c.

Using an arbor press, press the bearing into the

head in one continuous motion, until it is flush with

(or slightly below) the inside face of the head.

Starting and stopping the pressing motion may

result in a cracked bearing.

d. Ensure that the hole in the face of the head is open

after inserting the bushing. See figure 7a.

5.

CYLINDER BORE

Examine the cylinder bore carefully for tiny ‘pin head’

projections caused by foreign material in some fluids.

Carefully scrape off the small projections and smooth the

bore with emery as needed.

Summary of Contents for SNP1.25

Page 15: ...104 A00 Page 15 16 NOTES...