104-A00 Page 11/16

MAINTENANCE

PUMP ASSEMBLY

Before reassembling the pump, inspect all component

parts for wear or damage, and replace as required. Wash

out the bearing/seal recess of the head and remove any

burrs or nicks from the rotor and shaft.

1. Place a small amount of Moly-grease on all capscrews

before assembly to prevent galling.

2. Start with the OUTBOARD side of the pump.

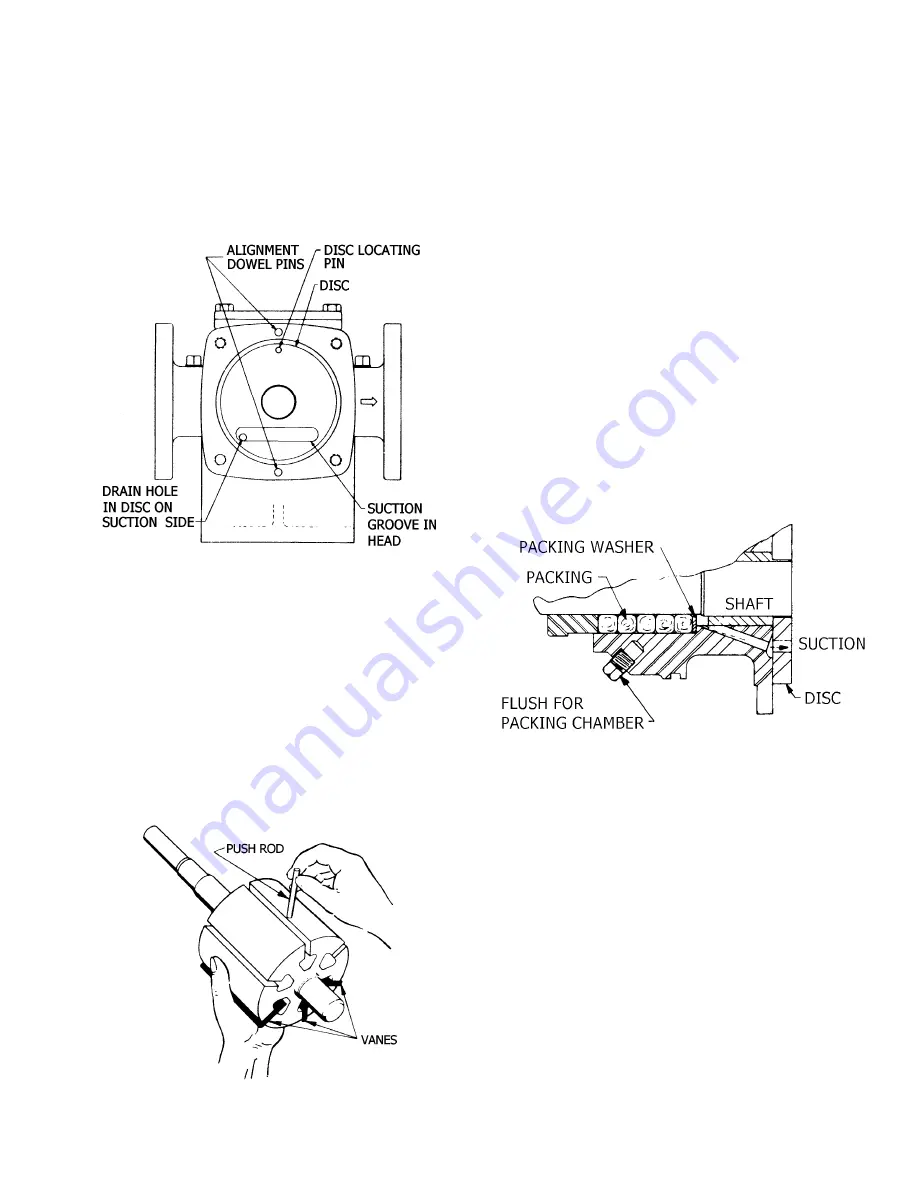

Figure 8 – Hole in Disc

3. Place the outboard disc (71) and seal ring (72) on the

cylinder (12) so that the hole in the disc will be toward

the INTAKE side of the pump. See Fig. 8.

4. Place the outboard head (23) on the cylinder (12) with

the suction groove toward the bottom, using the dowel

pin (25A) for alignment. See Figure 8.

a. Model SNPJ2.5: Place the O-rings (72A and 72B)

and the steam jacket (59) on the head.

b. All Models: Tighten the head capscrews evenly to

ensure that the head is properly seated and the seal

ring fully compressed.

c.

Secure the bearing cover (27) and seal ring (26) to

the head with the four capscrews (28).

Figure 9 – Pushrod Installation

5. Rotor and Shaft

a. Install the pushrods and the 2 (or 3) bottom vanes

into the rotor. The rounded edge of the vanes must

be ouward to contact the bore of the cylinder and

the relief grooves facing in the direction of rotation.

See Figs. 5 and 9

b. Holding the vanes in place, install the rotor/shaft into

the cylinder using care not to damage the disc or

shaft.

c.

Turn the shaft by hand until an empty slot comes to

the 12 o’clock position, insert a vane, and move on

to the next slot.

6. Place the inboard disc (71) and seal ring (72) on the

cylinder (12) so that the hole in the disc will be toward

the INTAKE side of the pump. See Fig. 8.

7. Place the inboard head over the shaft and against the

cylinder (12) with the suction groove toward the bottom,

using the dowel pin (25A) for alignment. See Figure 8.

a. Jacketed Models: Place the O-rings (72A and 72B)

on the head.

b. All models except the SNP3A: Place the Bracket /

Jacket (108 or 59) onto the head.

c.

All models: Tighten the head capscrews evenly to

ensure that the head is properly seated and the seal

ring fully compressed.

Figure 10 - Packing

8.

PACKING AND PACKING FOLLOWER

When necessary to repack, use a full set of new packing

rings. Packing is furnished in sets with the correct number of

rings. Never add new rings to an old set of packing.

a. Insert the packing washer (58) into the stuffing box

of the

inboard hub.

b. Insert each packing ring (19) separately into the

stuffing box, using the packing follower (75) to

properly seat each ring after placement. Be sure to

stagger the split joints approximately 180 degrees

apart so that they are not overlapping or near the

joint of the preceding ring.

c.

Install and tighten the two packing follower studs

(17).

d. Place the packing follower (75) snugly against the

packing. Install the two packing follower stud nuts

(18) and

tighten lightly. NOTE:

Adjustment to the

packing follower should be made while pumping

liquid (see "Packing Adjustment").

Summary of Contents for SNP1.25

Page 15: ...104 A00 Page 15 16 NOTES...