104-A00 Page 8/16

MAINTENANCE

Hazardous

machinery can

cause serious

personal injury.

Failure to disconnect and lockout

electrical power or engine drive before

attempting maintenance can cause

severe personal injury or death

Hazardous

machinery can

cause serious

personal injury.

Failure to stop the pump before

adjusting the shaft packing can cause

severe personal injury.

Hazardous pressure

can cause personal

injury or property

damage

Failure to relieve system pressure prior

to performing pump service or

maintenance can cause personal injury

or property damage.

Hazardous voltage.

Can shock, burn or

cause death.

Failure to disconnect and lockout

electrical power before attempting

maintenance can cause shock, burns or

death

Hazardous pressure

can cause personal

injury or property

damage

Disconnecting fluid or pressure

containment components during pump

operation can cause serious personal

injury, death or major property damage

Hazardous or toxic

fluids can cause

serious injury.

If pumping hazardous or toxic fluids,

system must be flushed and

decontaminated, inside and out, prior to

performing service or maintenance

NOTICE:

Maintenance shall be performed by qualified technicians

only. Following the appropriate procedures and

warnings as presented in this manual.

SCHEDULED MAINTENANCE

STRAINERS

Strainers must be cleaned regularly to avoid pump starvation.

Schedule will depend upon the application and conditions.

LUBRICATION

NOTICE:

To avoid possible entanglement in moving parts do not

lubricate the gear reducer or any other parts while the

pump is running

.

Sleeve bearings (bushings) are lubricated by the liquid being

pumped. Additional lubrication is not required.

IF EQUIPPED: Blackmer gear reducers are shipped from the

factory without oil in the gearcase. Fill with the grade of oil

indicated on the reducer tag. Change the oil after the first 48

hours of use and approximately every 500 hours of use

thereafter.

VANE REPLACEMENT

NOTICE:

Maintenance shall be performed by qualified technicians

only. Follow the appropriate procedures and warnings

as presented in manual.

1. Remove the head assembly and all other parts on the

outboard (non-driven) side of the pump. See the "Pump

Disassembly" Section.

2. Turn the shaft by hand until a vane (14) comes to the top

(12 o'clock) position of the rotor.

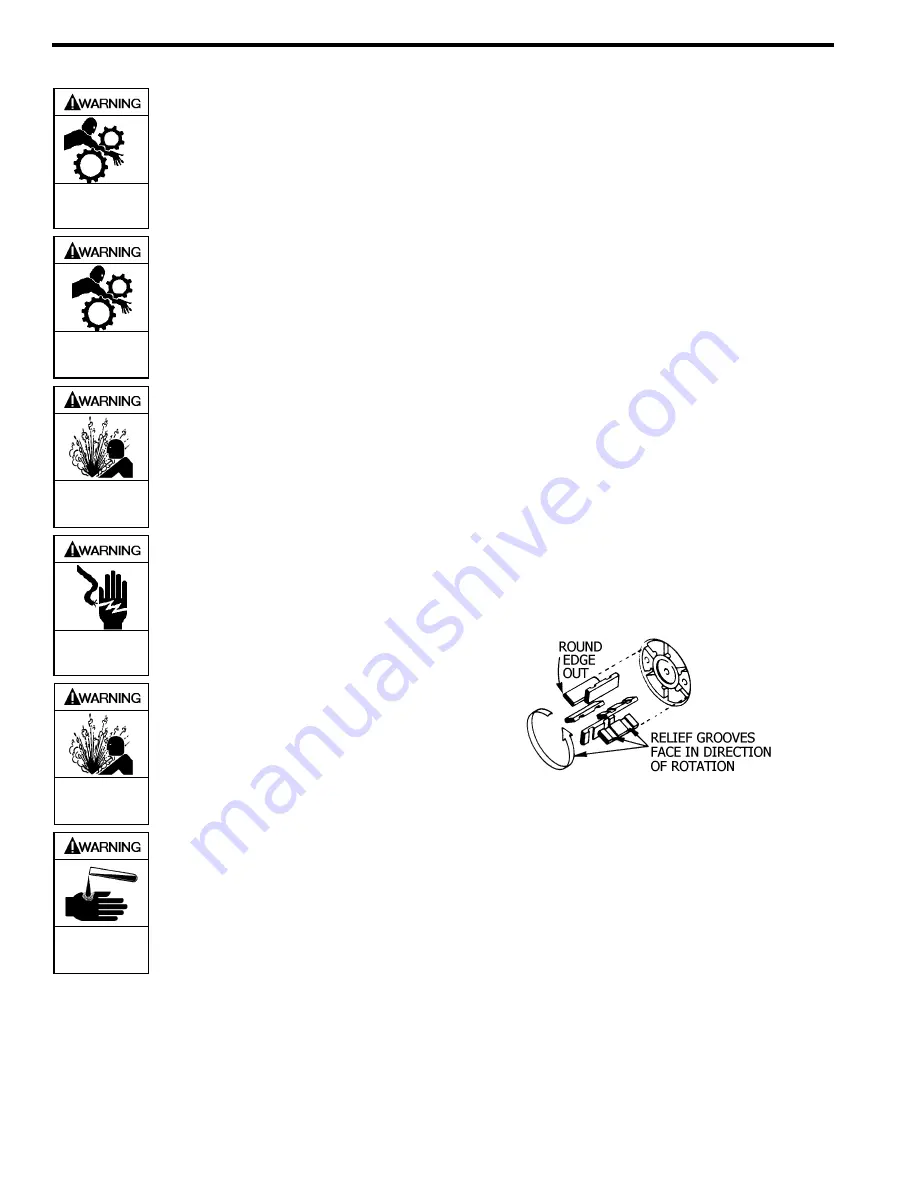

Figure 5 – Vane Replacement

3. Remove and replace the vane, making sure to install the

vane with the rounded edge outward to contact the

cylinder.

4. Rotate the shaft until the next rotor slot is in the top

position, and replace the vane.

5. Continue this procedure until all new vanes are in place.

6. Reassemble the pump as instructed in "Pump

Assembly."

Summary of Contents for SNP1.25

Page 15: ...104 A00 Page 15 16 NOTES...