104-A00 Page 9/16

MAINTENANCE

PUMP DISASSEMBLY

NOTICE:

Follow all hazard warnings and instructions provided in

the “Maintenance” section of this manual.

NOTE:

The numbers in parentheses following individual parts

indicate reference numbers on the Pump Parts List.

1. On the outboard (non-driven) side of the pump, remove

the head capscrews (21A), head (23) and disc (71).

Avoid damaging the head seal ring (72) and disc (71).

NOTE:

The sleeve bearing (bushing) (24) is press fit into

the head and should not be removed unless replacement

is necessary (see "Sleeve Bearings").

2. Turn the shaft by hand until a vane (14) comes to the top

(12 o'clock) position of the rotor. Remove each vane in

turn.

3. On the opposite (inboard) end of the pump, clean the

pump shaft thoroughly, making sure the shaft is free of

nicks, burrs, or paint that might damage the packing or

mechanical seal when the inboard head is removed.

4.

PUMPS EQUIPPED WITH PACKING

a. Remove the packing locknuts (18), studs (17) and

packing follower (75).

b. Remove the head capscrews (21), bracket (108),

head (20) and disc (71). Avoid damaging the head

seal ring (72) and disc (71).

NOTE:

The sleeve

bearing (24) is press fit into the head and should not

be removed unless replacement is necessary (see

"Sleeve Bearings").

c.

The packing rings (19) and packing washer (58) can

be pulled from the inboard hub with the use of a

corkscrew tool or screwdriver.

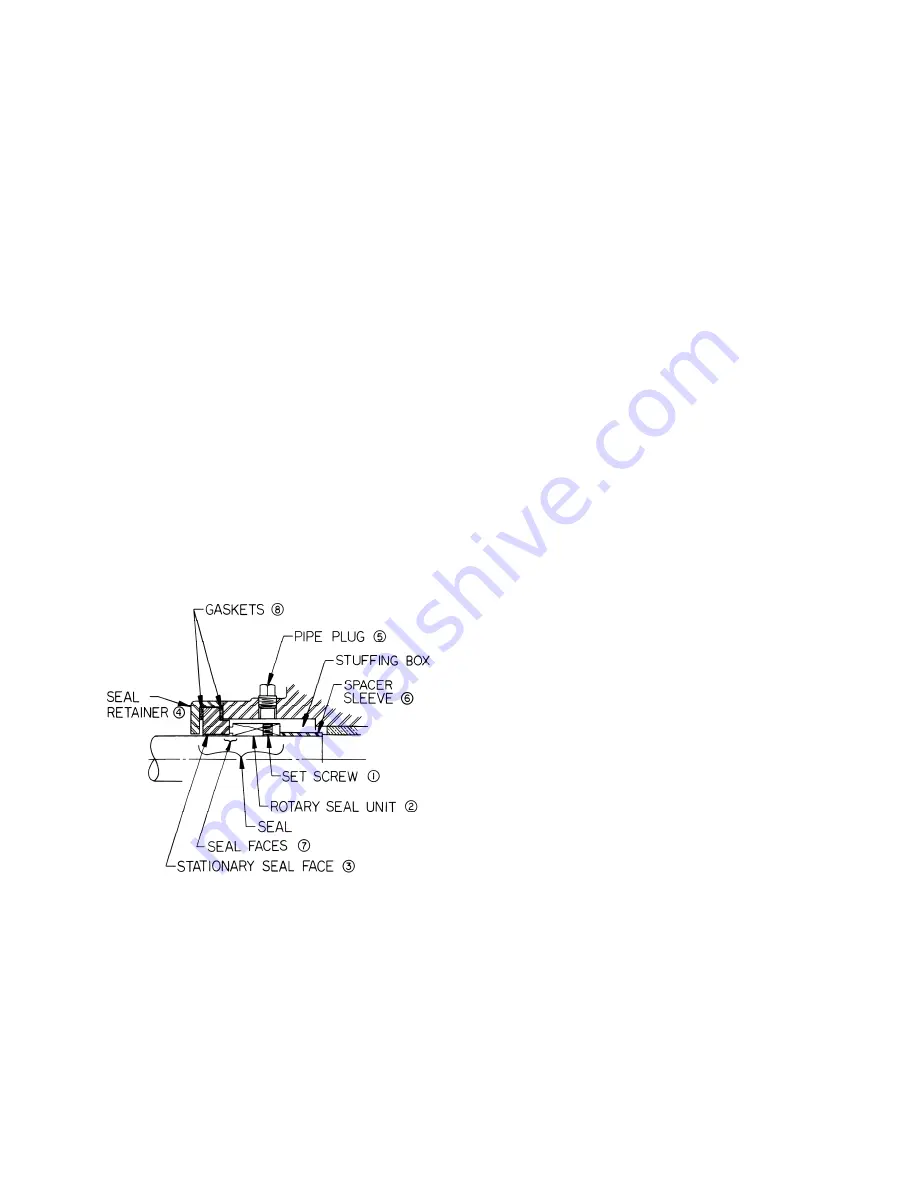

F i g u r e 6 – C o m m e r c i a l M e c h a n i c a l S e a l

5.

PUMPS EQUIPPED WITH BLACKMER TRIPLE-LIP

SEAL OR A COMMERCIAL MECHANICAL SEAL

a. Loosen all setscrews before removing the head

assembly. For further instructions on the

disassembly and assembly of commercial

mechanical seals, refer to the separate literature

accompanying the seal.

b. Remove the head capscrews (21), bracket (108),

head (20) and disc (71). Avoid damaging the head

seal ring (72) and disc (71).

NOTE:

The sleeve

bearing (24) is press fit into the head and should not

be removed unless replacement is necessary (see

"Sleeve Bearings").

6. From the driven side of the pump, grasp the rotor in the

3 and 9 o'clock positions, and gently pull the rotor and

shaft (13) out of the cylinder.

CAUTION:

Use care to

avoid injury-the rotor and shaft is heavy and may have

sharp edges.

PARTS REPLACEMENT

1. If any of the O-rings have been removed or disturbed

during disassembly, they must be replaced with new O-

rings.

NOTE:

PTFE O-rings should be heated in hot

water to aid installation.

2. Excessive or continuous leakage around the pump shaft

may be an indication of a damaged mechanical seal,

worn packing, or a damaged or worn sleeve bearing.

a. If a mechanical seal has been leaking, it is

recommended the entire seal be replaced. Refer to

"General Pump Troubleshooting" for possible

causes of seal leakage.

b. If the packing is leaking excessively, refer to

"Packing Adjustment." If this does not solve the

problem, a complete new set of packing rings

should be installed.

c.

If the pump shaft indicates an excessive amount of

radial "play," the sleeve bearing in the hub should be

replaced.

3. Worn or scored discs may be reused if interchanged

from one head to the other with the new side toward the

rotor.

Summary of Contents for SNP1.25

Page 15: ...104 A00 Page 15 16 NOTES...