105-A00 page 4/12

INSTALLATION

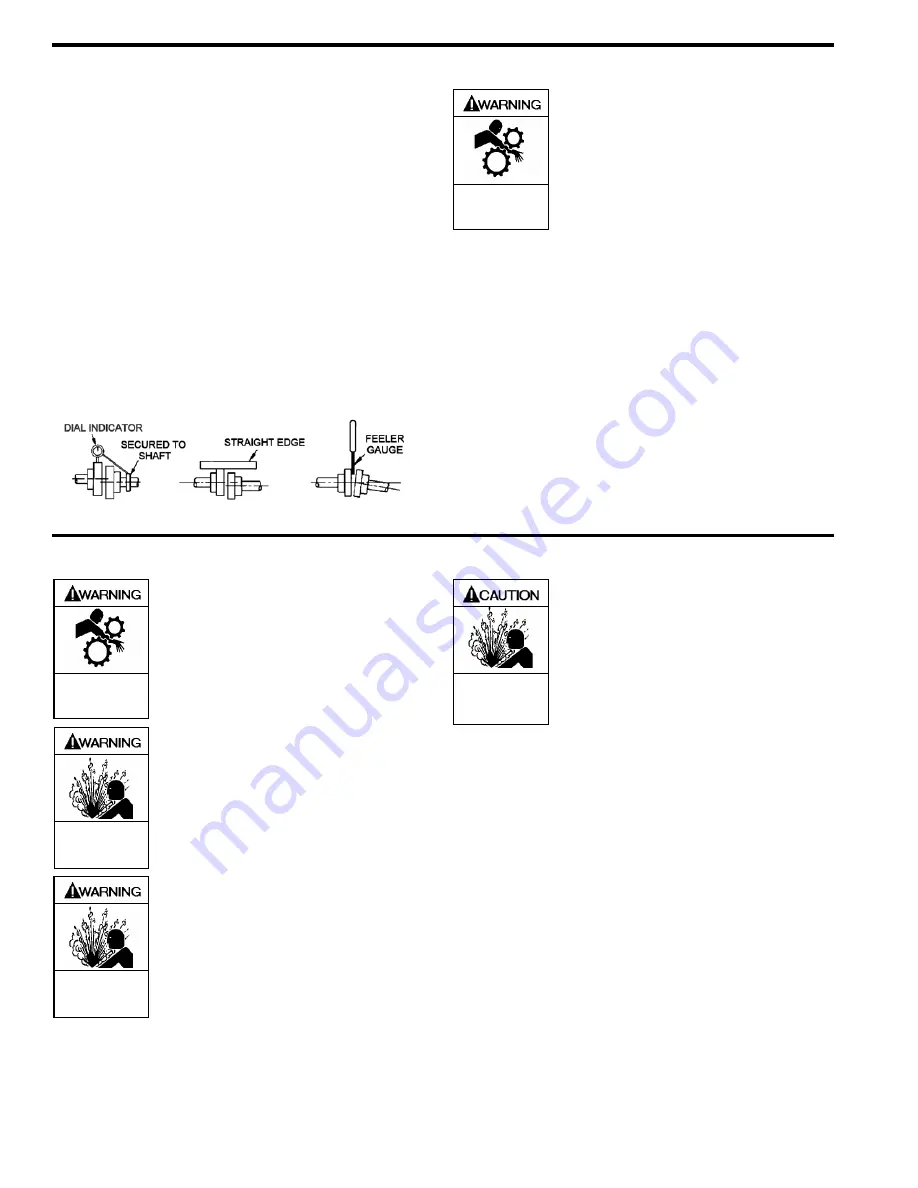

COUPLING ALIGNMENT

The pump must be directly coupled to a gear reducer and/or

driver with a flexible coupling. Both angular and parallel

coupling alignment MUST be maintained between the pump,

gear, motor, etc. in accordance with manufacturer’s

instructions. See Figure 4.

1. Parallel alignment: The use of a laser alignment tool or

dial indicator is preferred. If a laser alignment tool or

dial indicator is not available, use a straightedge. Turn

both shafts by hand, checking the reading through one

complete revolution. Maximum offset should be less

than .0005" (0.127 mm).

2. Angular alignment: Insert a feeler gauge between the

coupling halves. Check the spacing at 90° increments

around the coupling (four checkpoints). Maximum

variation should not exceed 0.005" (0.127 mm). Some

laser alignment tools will check angular alignment as

well.

3. Replace the coupling guards after setting alignment.

Figure 4 – Coupling Alignment

Do not operate

without guard

in place

OPERATION WITHOUT GUARDS IN

PLACE CAN CAUSE SERIOUS

PERSONAL INJURY, MAJOR

PROPERTY DAMAGE, OR DEATH.

PUMP ROTATION

NOTICE:

CONFIRM CORRECT PUMP ROTATION BY CHECKING

THE PUMP ROTATION ARROWS RESPECTIVE TO PUMP

DRIVER ROTATION.

TO CHANGE PUMP ROTATION

To reverse rotation, the pump must be disassembled then

reassembled with the shaft on the opposite side of the pump.

See the ‘Maintenance’ section for instructions.

OPERATION

Do not operate

without guard

in place

OPERATION WITHOUT GUARDS IN

PLACE CAN CAUSE SERIOUS

PERSONAL INJURY, MAJOR

PROPERTY DAMAGE, OR DEATH.

Hazardous pressure

can cause personal

injury or property

damage

DISCONNECTING FLUID OR PRESSURE

CONTAINMENT COMPONENTS DURING

PUMP OPERATION CAN CAUSE

SERIOUS PERSONAL INJURY, DEATH

OR MAJOR PROPERTY DAMAGE.

Hazardous pressure

can cause personal

injury or property

damage

FAILURE TO RELIEVE SYSTEM

PRESSURE PRIOR TO PERFORMING

PUMP SERVICE OR MAINTENANCE

CAN CAUSE PERSONAL INJURY OR

PROPERTY DAMAGE.

Hazardous pressure

can cause personal

injury or property

damage

PUMPS OPERATING AGAINST A

CLOSED VALVE CAN CAUSE SYSTEM

FAILURE, PERSONAL INJURY AND

PROPERTY DAMAGE

PRE-START UP CHECK LIST

1. Check the alignment of the pipes to the pump. Pipes

should be supported so that they do not spring away or

drop down when pump flanges or union joints are

disconnected.

2. Check the entire pumping system to verify that the proper

inlet and discharge valves are fully open, and that the

drain valves and other auxiliary valves are closed.

3. Install suction and discharge pressure gauges on the

pump in the threaded connections provided. These can be

used to check actual suction and discharge conditions

after pump start-up.

4. Check the wiring of the motor.

5. Briefly start the pump to verify proper rotation direction.

Summary of Contents for XLW1 1/2

Page 11: ...105 A00 Page 11 12 NOTES...