105-B00 Page 4/16

COUPLING ALIGNMENT – LONG

COUPLED

The pump must be directly coupled to a gear and/or driver

with a flexible coupling. Verify coupling alignment after

installation of new or rebuilt pumps. Both angular and

parallel coupling alignment MUST be maintained between

the pump, gear, motor, etc. in accordance with

manufacturer’s instructions. See Figure 3.

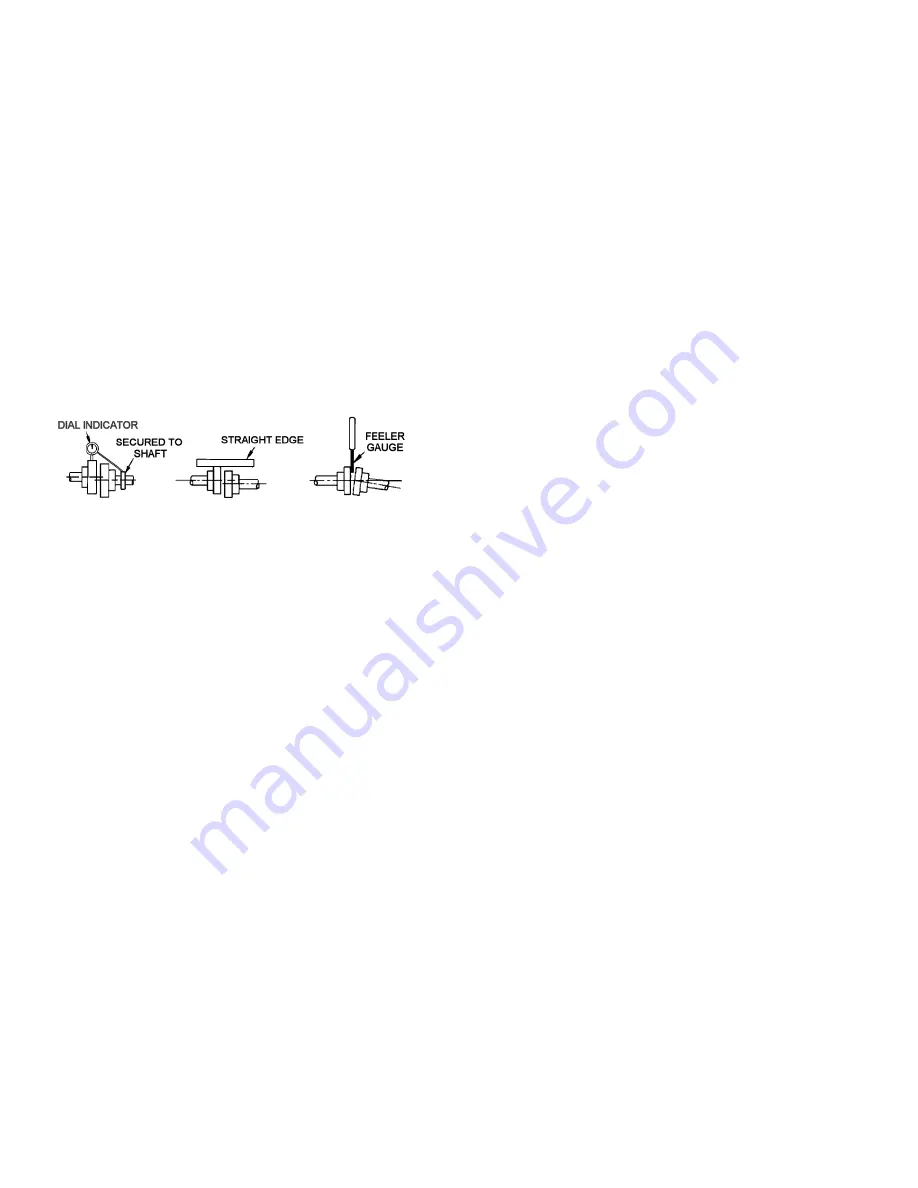

1. Parallel alignment: The use of a laser alignment tool or

dial indicator is preferred. If a laser alignment tool or

dial indicator is not available, use a straightedge. Turn

both shafts by hand, checking the reading through one

complete revolution. Maximum offset should be less

than .005" (.127 mm).

2. Angular alignment: Insert a feeler gauge between the

coupling halves. Check the spacing at 90° increments

around the coupling (four checkpoints). Maximum

variation should not exceed .005" (.127 mm). Some

laser alignment tools will check angular alignment as

well.

3. Replace the coupling guards after setting alignment.

Figure 3 – Alignment Check

ALIGNMENT – FLANGE MOUNTED GEAR

REDUCER

If the unit is assembled with a Blackmer Flange Mounted Gear

Reducer, no coupling alignment is required. The motor,

gearbox, and pump are rigidly connected with bolted, flange

connections. These flanges ensure the motor shaft, gearbox

shafts, and pump shaft are aligned correctly, without the need

for manual alignment. However, due to variations in base and

foundation geometry the unit will require shimming to reduce

stress on the gearbox and pump adapter. See

PRESTART

CHECKLIST

section for details.

PUMP ROTATION

A right-hand pump rotates clockwise with the intake on the

right side, when viewed from the driven end.

A left-hand pump rotates counterclockwise with the intake on

the left side, when viewed from the driven end.

TO REVERSE PUMP ROTATION

To reverse rotation, the pump must be disassembled then

reassembled with the shaft on the opposite side of the pump.

See the ‘Maintenance’ section for instructions.

CHECK VALVES

The use of check valves or foot valves in the supply tank is

not recommended with self-priming, positive displacement

pumps.

If the possibility of liquid backflow exists when the pump is off,

a check valve in the pump discharge piping is recommended

because the pump can motor in the reverse rotation and

create undue stress on all attached components. Never start

a pump when it is rotating in the reverse rotation as the added

starting torque can damage the pump and related equipment.