107-B00 Page 9/16

PUMP ASSEMBLY

Before reassembling the pump, inspect all component

parts for wear or damage, and replace as required. Wash

out the bearing/seal recess of the head and remove any

burrs or nicks from the rotor and shaft.

Reassemble the OUTBOARD side of the pump first:

For a CLOCKWISE rotation pump, position the pump

cylinder with the INTAKE port to the

left

.

For a COUNTERCLOCKWISE rotation pump, position

the pump cylinder with the INTAKE port to the

right

.

1. Install the liner key (74) in the slot located in the top of the

liner. Align the key with the notch in the top of the pump

casing and start the liner into the casing.

The word “INTAKE” cast on the liner must face the intake

port of the pump casing. Uniformly tap the outer edge of

the liner with a rubber mallet to fully insert into the casing.

2. On 2 and 3-inch models, place the disc (71) against the

liner with the seal cavity outward.

3. On 4-inch models, attach the disc to the outboard head

without the mechanical seal components. Install disc

machine screws (71A) and lockwashers (71B)

4. Without installing the head O-ring or mechanical seal

components, temporarily attach the outboard head and

bearing to the casing. Install and hand-tighten two head

capscrews, 180 degrees apart. This head will be used to

hold and align the rotor and shaft while the inboard side

of the pump is assembled.

5. Turn the pump around to begin assembly on the inboard

side. Before installing the rotor & shaft assembly, the

direction of pump rotation must be determined as

indicated under the “Pump Rotation” section of this

manual.

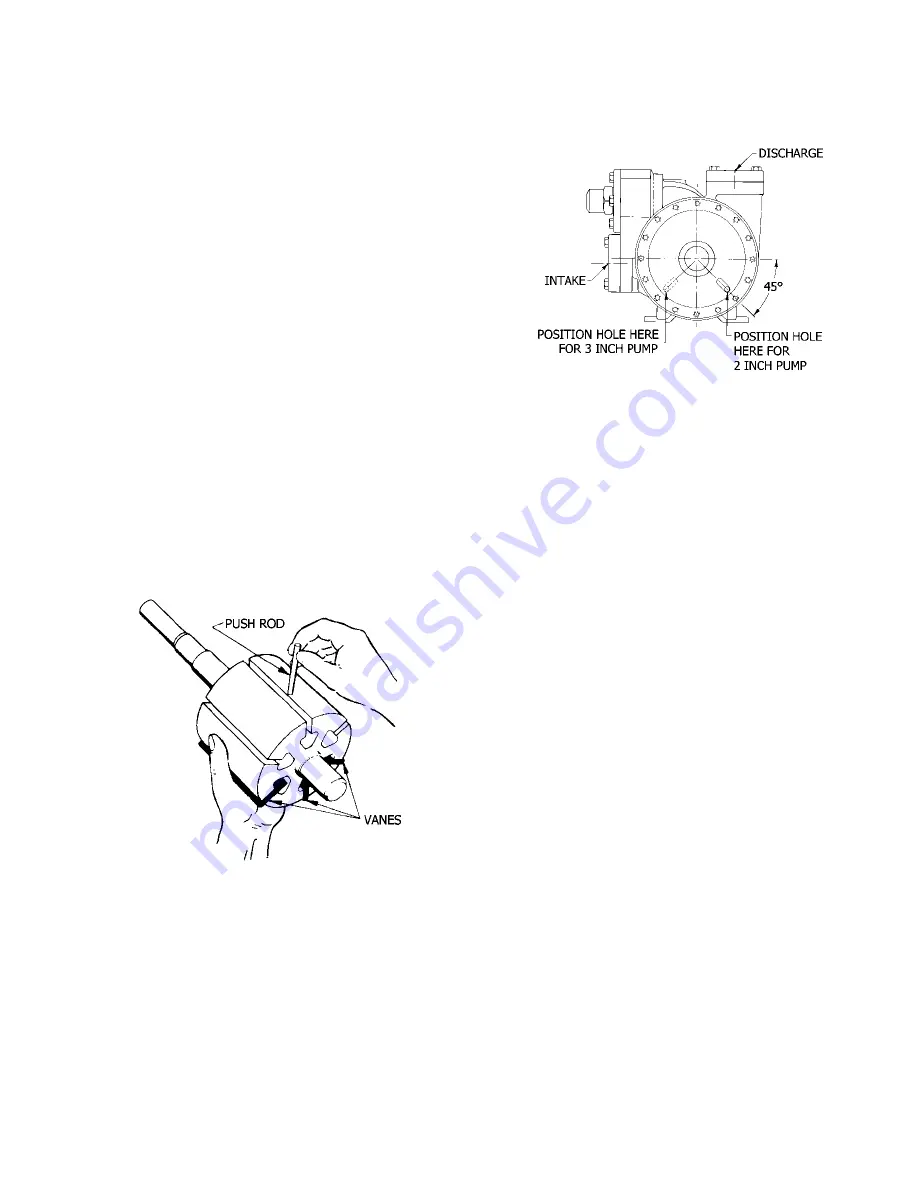

Figure 5 – Pushrod Installation

6. Remove the vanes (14) and push rods (77) from the rotor

and shaft assembly. Inspect for wear and damage, and

replace as follows:

a. Insert the vanes into the bottom three rotor slots with

the relief grooves facing in the direction of pump

rotation, and with the rounded edges outward. See

Figure 4.

b. Hold the three bottom vanes in place while inserting

the three push rods (77). See Figure 5.

c. After the bottom vanes and push rods are installed,

carefully insert the non-driven end of rotor and shaft

into the casing.

d. Install the remaining vanes into the top positions of

the rotor.

7. DISC – 2 and 3-inch Models

Install the disc (71) on the inboard side of the pump with

the seal cavity facing outward and the disc relief hole

located as shown in Figure 6.

Figure 6 – Disc Relief Hole Location

2 and 3-inch Models

8. MECHANICAL SEAL – 2 and 3-inch Models

Rotating Assembly

a. Apply a small amount of motor oil on the shaft

between the shaft threads and the rotor.

b. Slide the seal jacket assembly (153C) over the shaft

and into the disc cavity with the drive tangs of the

jacket towards the rotor. Rotate the jacket assembly

to engage the drive tangs in the rotor slots.

c. Install a new rotating O-ring (153E) in the rotating seal

face (153B). Align and insert the rotating assembly

into the the seal jacket with the polished face outward.

Clean the polished face with a clean tissue and

alcohol.

Stationary Seat

a. Apply a small amount of motor oil in the seal access

of the head.

b. Install a new stationary O-ring (153D) in the stationary

seat (153A). Clean the polished face with a clean

tissue and alcohol. Align the pin in the stationary seat

with the slot in the head recess and push the seat

fully into the seal recess with the polished face

outward.

9.

DISC and MECHANICAL SEAL – 4-inch Models

a. Before attaching the disc, apply a small amount of

motor oil in the recess of the head.

b. Install a new stationary O-ring (153D) in the

stationary seat (153A). Align the pin in the stationary

seat with the slot in the head recess and push the

seat fully into the seal recess with the polished face

outward. Clean the polished face with a clean tissue

and alcohol.

c.

Install a new rotating O-ring (153E) in the rotating

seal face (153B). Clean the polished face with a

clean tissue and alcohol. Place the polished face of

the rotating seal against the face of the stationary

seat in the head.

d. Align and install the seal jacket assembly (153C)

over the rotating face with the drive tangs outward.

e. Carefully place the disc on the head with the seal

cavity inward. The drive tangs of the seal jacket

should protrude through the center hole of the disc.