7

AODDAMPENER™

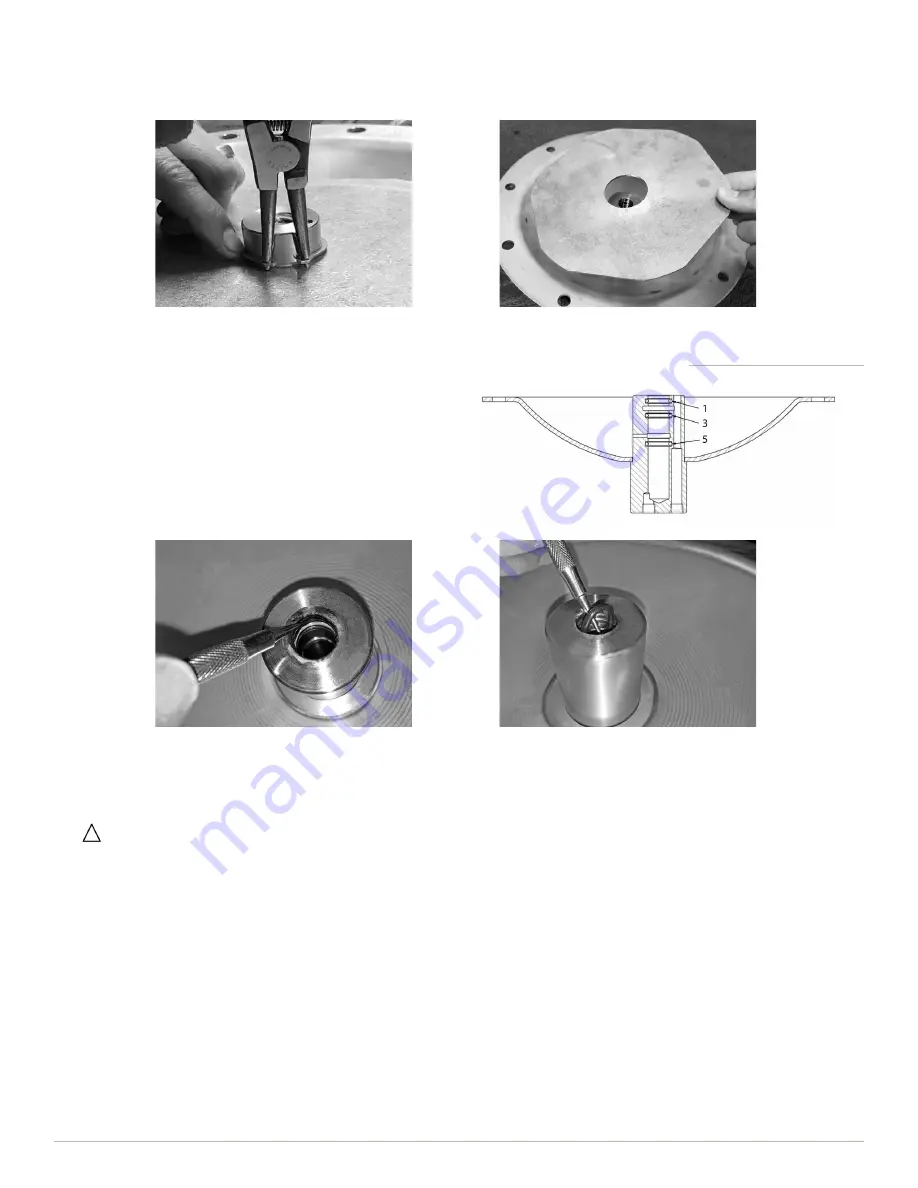

4. Apply a thin coat of lubricant (such as Molycote® 55 or equivalent) to new O-rings and install in grooves 5, 3 and 1 in that order

(Figure 2). The automatic valve will not operate if O-rings are installed in the wrong grooves.

Figure 2

O-Ring Replacement

1. There are five grooves in the automatic valve with O-ring

seals installed in grooves 1, 3 and 5 (Figure 2). O-rings in

the automatic valve should be replaced with each diaphragm

replacement. New O-rings are included in Diaphragm

Replacement Kits.

2. Secure the dampener non-wetted housing into a vise with soft

jaws with the inside (interior) of the housing facing up.

3. Using an O-ring pick, remove old O-rings from the automatic

valve and discard.

Install O-Rings

with

O-Ring Installation Tool:

It is highly recommended that the AODDampener O-Ring Installation Tool be used to install O-rings in the automatic valve to

ensure proper placement on reassembly. The tool is engineered to properly install O-rings one at time in the correct position

and is available in three sizes to fit 1” inlet models, 1.5 and 2” inlet models, and 3” inlet models. Refer to

Replacement Kits

and Tools

above.

a. Using the appropriate size O-Ring Installation Tool, insert the O-ring tool slide into the body of the tool until O-ring grooves align.

b. Position the first O-ring into the first groove on the tool to install the O-ring in groove 5 of the automatic valve. Use your finger to

cover the top of slide to prevent the O-ring from slipping out of place and push the slide forward to properly position the O-ring

on the tool.

c. With the slide held in place, insert the tool into the automatic valve until the shoulder of the tool is flush with the top of the valve.

Hold the tool in place and carefully remove the slide from the tool body. Remove the entire tool from the automatic valve and

confirm the O-ring is properly seated in groove 5.

d. Reinsert the O-ring tool slide into the body of the tool until O-ring grooves align and repeat steps above to install the two

remaining O-rings. Use the second groove on the tool to install the second O-ring in groove 3 of the automatic valve, and the

third groove on the tool to install the third O-ring in groove 1 of the automatic valve.

8. AODDampener models are equipped with a backup plate attached to the non-wetted housing to minimize damage to the

diaphragm if the dampener loses charge. The backup plate is held in place by two retaining rings. It is not necessary to remove the

backup plate during disassembly, except when necessary to clean any oil residue or remove debris from the non-wetted housing.

To remove the backup plate, remove the retaining ring using snap ring pliers and lift the backup plate off the housing.