9

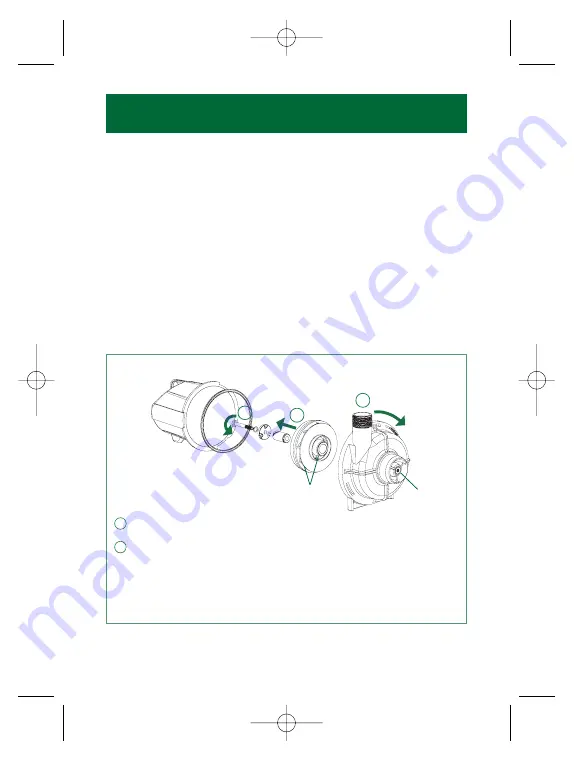

MAINTENANCE & CLEANING

Remove the pump motor from the impeller/rotor housing by holding the housing

while turning the motor clockwise (see arrows provided on the pump).

Dismantle the Impeller/Rotor assembly by undoing the centre bolt ensuring the

washer is kept in a safe place.

NB: THIS IS A LEFT-HAND THREADED BOLT SO

MUST BE UNSCREWED IN A CLOCKWISE DIRECTION (THE OPPOSITE TO A

NORMAL THREAD DIRECTION).

Remove the ceramic thrust washer, the ceramic

shaft and the impeller rotor assembly from the impeller/rotor housing.

Clean all parts of the impeller in fresh water ensuring that the impeller vanes and

impeller inlet are clean.

MONTHLY MAINTENANCE

1

2

Routine Maintenance

Carry out routine maintenance when pump flow is visibly reduced.

1. Switch off electricity to the pump, and all other electrical pond equipment.

2. Remove pump from pond (do not use the cable to lift the pump).

3. Open pre-filter by unscrewing the pump flange from the outlet of the pump

and opening the pre-filter lock with a coin.

4. Remove pump (see getting to know your Amphibious Pre-Filter). Wash the

pre-filter and impeller inlet thoroughly in fresh water.

A blocked pre-filter and impeller inlet will reduce the pump flow rate.

Monthly Maintenance

Follow steps 1 to 4 as per Routine Maintenance.

The impeller and impeller inlet can become blocked by pond waste.

Clean the impeller according to the following instructions.

Follow steps 1 to 4 as per Routine Maintenance.

1

2

2

Impeller

Vanes

Impeller

Inlet

Amphibious Pump Leaflet 2.qxd 30/3/06 13:33 Page 11