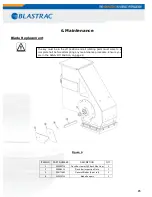

Check the air cleaner and change when dirty.

Check the hydraulic fluid and change when dirty.

Check the Blast Seals for excessive wear.

Check the Blower Bearings set screws and grease.

Check the chain tension in the steering assembly.

Check the condition and tension of the belts.

Check the bearing in the idler assembly.

Make sure the dust bags are empty.

Important Note: Please comply with the local waste treatment regulations considering

the removed material.

Check the dust collector latches and ensure thay they firmly secure the door.

Check the separator parts for wear and defects. Remove foreign bodies and

dust deposits in order to prevent the separator from being blocked.

Check the level of abrasive in the storage hopper. Refill if necessary.

Any items on this list that are not found to be in order must be repaired or replaced.

Operator Awareness

The 1-16DB4-V2 machine is designed to blast a concrete surface and reclaim all

shot and dust. The machine can very easily destroy the concrete surface if not

operated properly! The absence of operator awareness will create down time and

can prove to be very costly.

•

When the shot valve is open, the machine is throwing shot! Therefore, you

must be sure the shot valve is closed prior to starting as well as any time

the machine comes to a stop.

•

The speed of travel controls the level of removal. You should run a test

pattern to be sure you are not gouging the floor.

•

Due to variances in concrete, it is necessary to check the pattern every

ten feet as the concrete or coated surface may be softer in different areas.

•

The maintenance check list on page 12-13 is provided for blasting

efficiency. This list should be completed after each day of blasting.

•

If the dust bags get too full, you will lose all of your suction. This will result

in loss of all shot from the hopper.

13

Engine exhaust gases contain poisonous carbon monoxide. Carbon

Monoxide is odorless and colorless and can cause injury or death if inhaled.

Do not use equipment indoors without adequate ventilation. Refer to OSHA

guidelines and regulations concerning maximum levels of exposure to

carbon monoxide gases and other hazards associated with using internal

combustion engines. It is highly recommended that a CO (carbon

monoxide) detector be used to warn the user if levels become unsafe.

Summary of Contents for 1-16DB4-V2

Page 1: ...SERVICE MANUAL 1 16 DB4 V2 VERSION 1 1 www blastrac com 1 800 256 3440...

Page 36: ...Check for leaks after starting theengine...

Page 38: ...35...

Page 40: ...36...

Page 42: ...37...

Page 44: ...38...

Page 46: ...39...

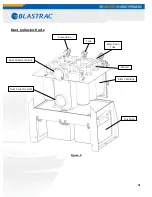

Page 50: ...BLASTRAC RS IN SURFACE PREPARATION Figure 12 43...

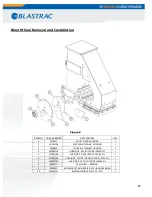

Page 57: ...BLASTRAC VATORS IN SURFACE PREPARATION Blast Head Assembly Figure 14 48...