.BLASTRAC

THE

INNOVATORS

IN

SURFACE PREPARATION

Care and maintenance work

Fuel

system

Specificat

i

ons

when working on the

fuel system

Engine must be

switche

d

off!

Smoking and naked lights prohibited!

No

i

nje

ction/highpressure

pipes may be

disco

nnected

while

the engine is running.

Cauti

on

when handling

ho

t

fuel!

Pay attention to

utmost

deanliness

when

refuelling

and w

o

rking on the

fue

l

system

.

C

lean

the

respective

affected parts careful-

ly. Blow damp

areas dry wtlh compressed

air.

Observe the

safety regulations and nation

-

al specifications for handling fue

l

s.

Dispose of leaking fuel and filter elements

properly.

Do

not allow fuel

to

seep away

into

the ground.

After all work

on

the fuel system, the sys-

tem should

be

vented, a

trial

run performed

and

the

tightness checked

.

It

will be necessary

t

o

vent

th

e

fue

l

syste

m

when

commiss

ioning

for the

first time, after

mainte

na

nce

work or if the tank

has

been

run dry.

C

le

an

and

dry

the engine

and eng

i

ne

com

-

l.:_g

partment thoroughly

before beginning

work.

Areas of

the eng

ine

compartment from

which dirt could

be loosened

must

be cov

-

ered

with a fresh

,

dea

n

foil.

Work on

the

fuel system may only

be

car-

ried out

in

an absolutely clean environment.

Contamination

of

the

air such as

dirt, dust

,

moisture

etc. must be

avoided.

Add

i

t

i

onalventing

of

the

fuel system

by

a

5

mi

nute

trial

ru

n

at

idle

speed or

on low loa

d

is absolutely essential.

Pay attention to utmost cleanliness due to

the high

prod

ucti

on

accuracy of

the

system!

The

f

uel

system must

be

l

ig

ht

and dosed.

Make a visual

i

nspection for leaks/damage

i

n

the

system.

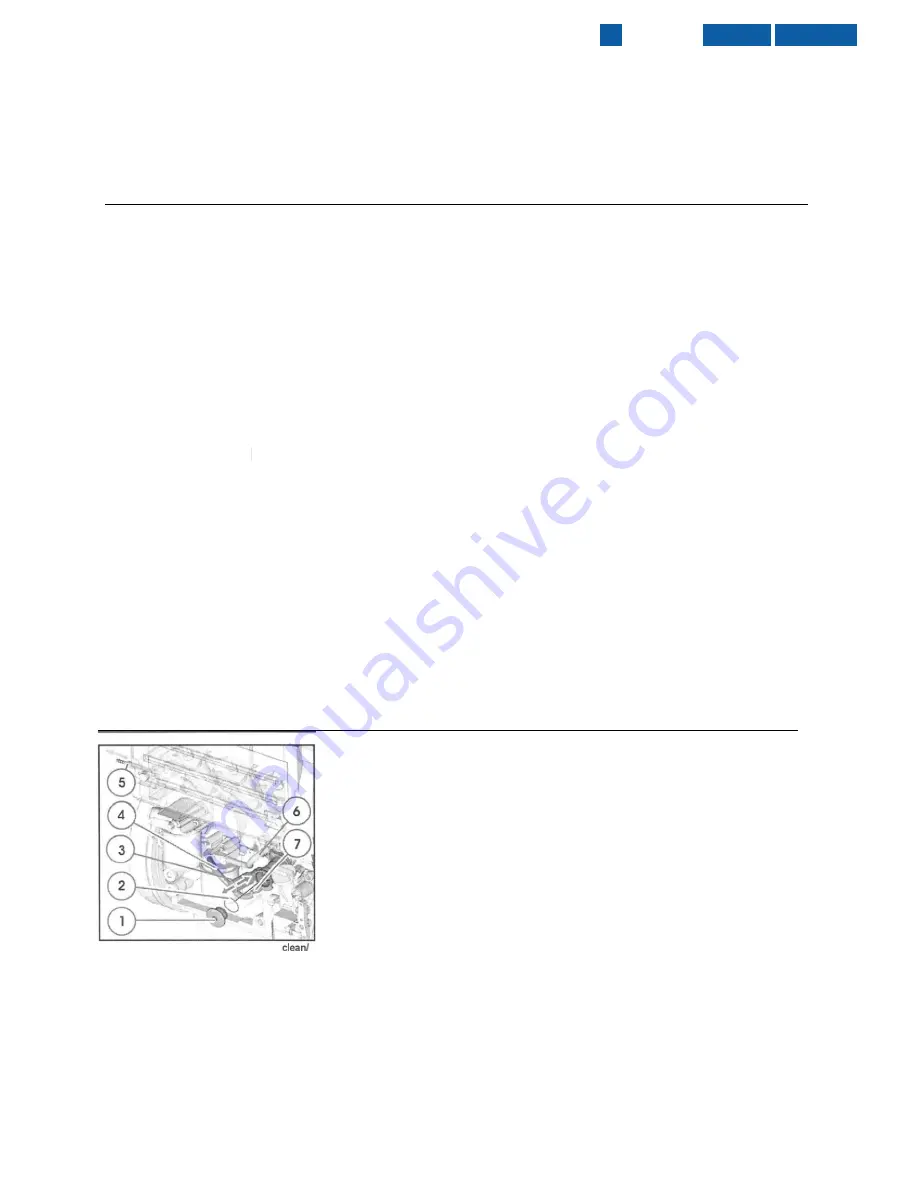

Fuel system

Care and maintenance work

Vent

the

fuel

system

•

Pump

in

the direction

of

the

arrow

(3)

until a

strong

resis

tance

i

s

felt

an

d

pressure

has

built

up.

•

The retu

rn line

(5)

must be

filled.

•

Start the engine

and

run in idle or on

l

ow

l

oad. A

i

r

is

pressed

through

the

return

pip

e

5)

to

the

tank.

Fuel

supply pump, sieve filter cartridge

change

•

Close fuel shutoff

tap (with

high-

l

evel

tank)

(sup-

ply

(7))

.

•

Remove

connect

i

on

(

4)

t

o the

fue

l

filter.

•

Catch

any escaping fuel.

•

Loosen screw

(

1

).

•

Remove fuel

screen

(screw (1

)

,

cover

and

fuelt

sc

re

en

form

one unit)

.

•

Take

t

h

e

sea

li

ng ring (2) and

clean it, renew

w

h

en damaged.

•

C

l

ean

c-0ve

r

-

fuel

screen w

ij

h

fuel

,

renew

de-

pending

on the condit

i

on.

•

Put

the

sea

l

ing ring (2)

in

position.

•

Mount

the cover-fue

l

filter with

screw

(1)

.

•

Re

i

nstallconnect

i

on (4) to t

h

e fuel filter.

•

Open

fue

l

shutoff tap supply

(7)

,

start eng

i

ne

and

34

run

i

n

i

d

l

e

or on

low

load

.

Summary of Contents for 1-16DB4-V2

Page 1: ...SERVICE MANUAL 1 16 DB4 V2 VERSION 1 1 www blastrac com 1 800 256 3440...

Page 36: ...Check for leaks after starting theengine...

Page 38: ...35...

Page 40: ...36...

Page 42: ...37...

Page 44: ...38...

Page 46: ...39...

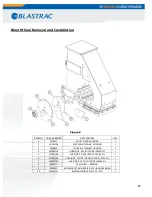

Page 50: ...BLASTRAC RS IN SURFACE PREPARATION Figure 12 43...

Page 57: ...BLASTRAC VATORS IN SURFACE PREPARATION Blast Head Assembly Figure 14 48...