Operating Instructions

2-45TDC

Maintenance

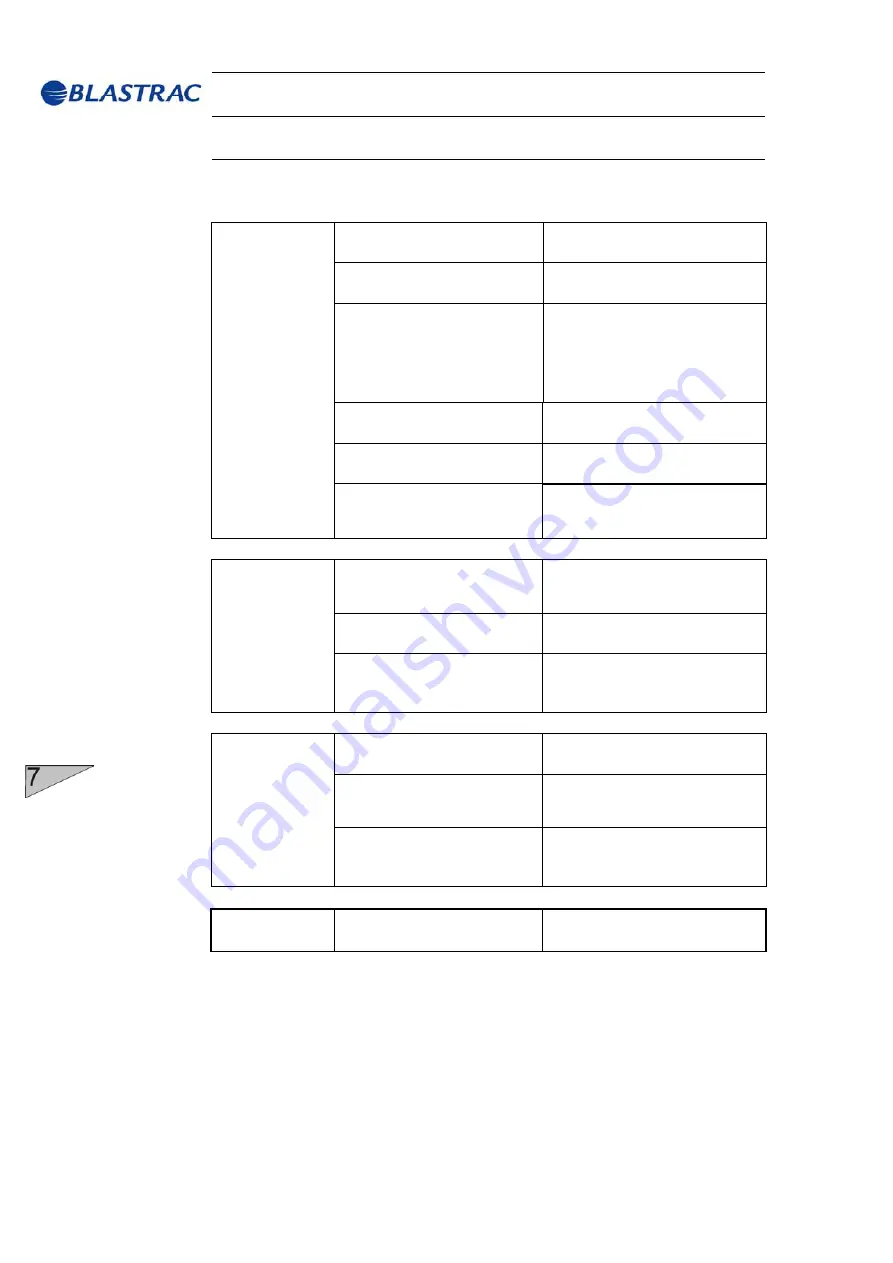

4

Weekly

Check the belt tension of the

HTD drives.

Allow 5 to 7 mm at approx. 10kg

both ways.

Check the belt tension of the V

belts.

Allow 5 to 7 mm at approx. 10kg

both ways.

Fill up the bearing units of the

machine with grease.

Depending on the use of the

machine pump two to three

strokes, use high temp LP 2

class grease. Only pump in

when running the wheels.

Lubricate the compressor

below the oil cooler with oil.

Up to half of the oil glass. Fill up

the compressor oil.

Check the bearing seals for

damage and wear.

Replace if necessary.

Check the shaft seals of the

rotating valves for release of

dust.

Replace if necessary.

Every month

Check the bearings of the

rotating valves for more/higher

noices.

Replace if necessary.

Check the motor reductors of

the rotating valves for leakage.

Lubricate frequently, replace if

necessary.

Check the rotor blades of the

rotating valves for wear or air

leakage.

Replace if necessary.

Every 3 months

Check the condition and

tension of the V belts.

Adjust or replace if necessary.

Fill up the bearing unit of the

blower with grease.

Depending on the use of the

machine pump two to three

strokes of grease at both sides.

Clean the upper section of the

filter unit.

Clean around the holes of the

tubes, clean tube and replace

cartridges if necessary.

Annually

Full overhaul and cleaning of

the complete machine.