2-45TDC Operating

Instructions

Maintenance

7

7.6 Tensioning the belts

The correct belt pre-tension is of great importance for the perfect

output transmission and for maintaining the normal service life of the

belts. Insufficient or excessive pre-tensioning frequently leads to

premature failure of the belts. Over-tensioning often causes bearing

defects in motors and bearing units.

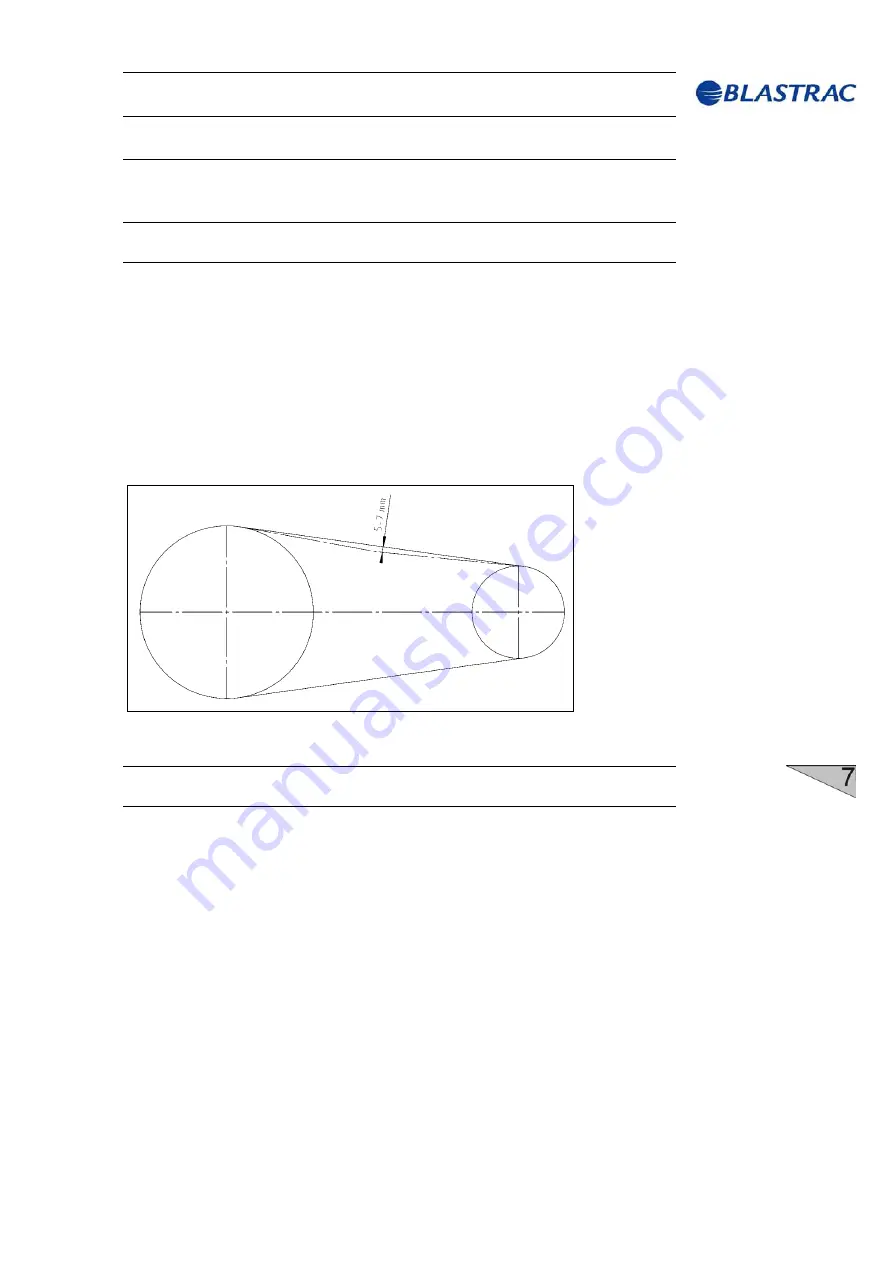

Check the correct pre-tension in accordance with fig. 7.1 by pressing

down the belt. The distance the belt can be pressed down should be

5-7 mm at approx. 10 kg.

Fig. 7.1

7.7 Taper

locks

Taper locks are used to shrink-fit hubs on shafts. Mounting and

demounting only requires a screw driver DIN 911 (Allan key).

Tightening and loosening is effected with the same threaded pins or

screws.

Taper locks are cylindrical on the inside, tapered on the outside and

slit longitudinally. The smaller bushes 2 and 3 have in the large face

their cylindrical blind holes in parallel to the axis which, however, are

only placed half in the bush material. The other halves of these blind

holes are threaded and are placed inside the hub.

Threaded pins or screws are screwed to the stop in the boreholes

using an Allan key. When the screws are tightened further using a

certain amount of force the hub is drawn up to the tapered bush

which is pressed onto the shaft with great force.