2-45D

Operating Instructions

General

5

The

Blastrac

blast cleaning machine 2-45D is a downward blasting

machine with a closed abrasive circuit designed for the pre-treatment

of horizontal surfaces. The bouncing impact of metallic abrasive onto

the surface to be treated thoroughly removes surface contaminants,

coats of paint, sealants and thin coatings.

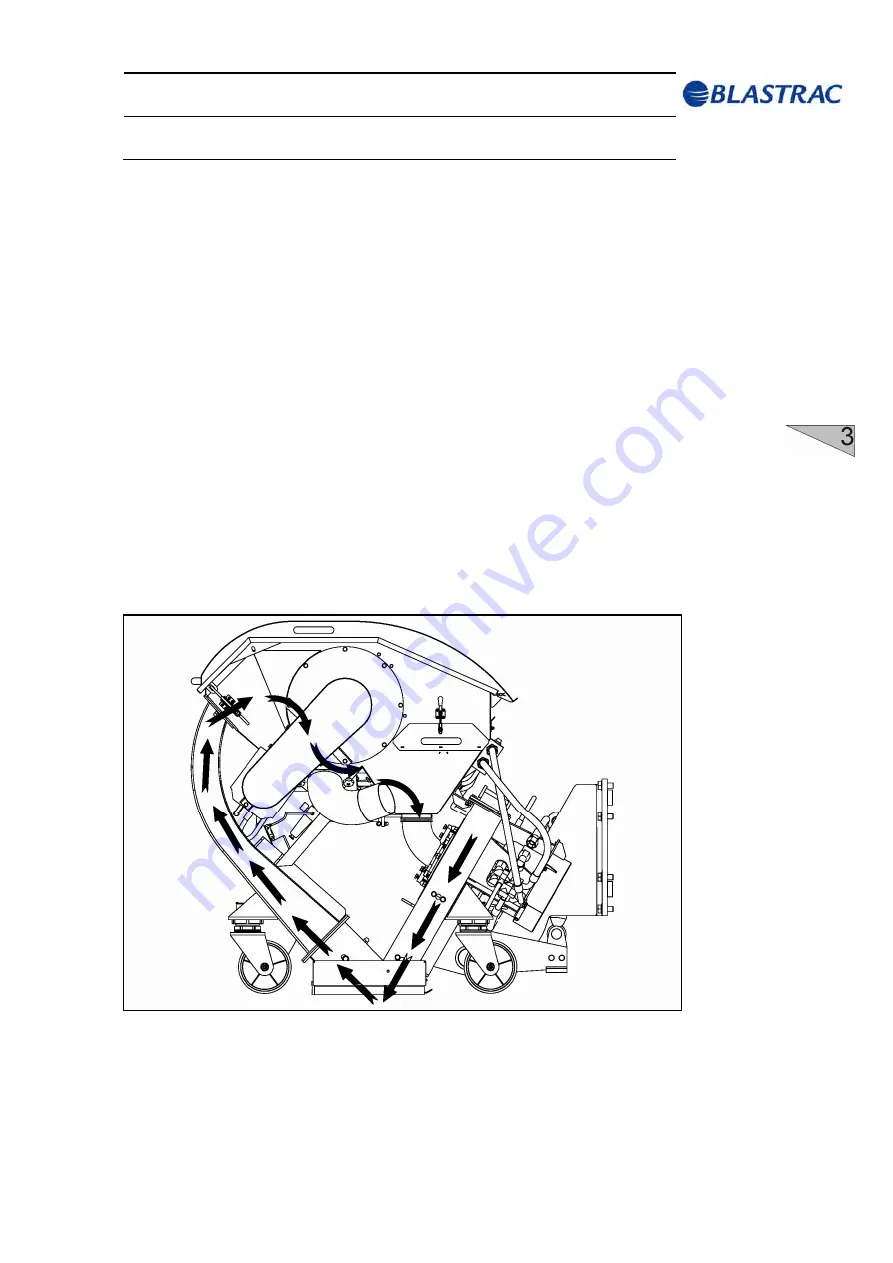

Like many revolutionary inventions the blast wheel method is based

on a simple principle: after mechanical pre-acceleration the abrasive

is thrown onto the surface at high speed by the blast wheel. Once the

abrasive has impacted on the surface it rebounds into a recovery

duct. The recovery duct deflects the abrasive into an air current

separator. Here dust and other contaminants are removed from the

abrasive so that only abrasive containing a very small amount of dust

is fed into the abrasive storage hopper for re-use by the blast wheel.

A suitable filter unit must be connected to the machine in order to

separate the dust from the abrasive.

A specially designed dust collection system ensures dust-free

operation of the machine and clean air at the workspace.

Fig. 3.2