Operating Instructions

2-45D

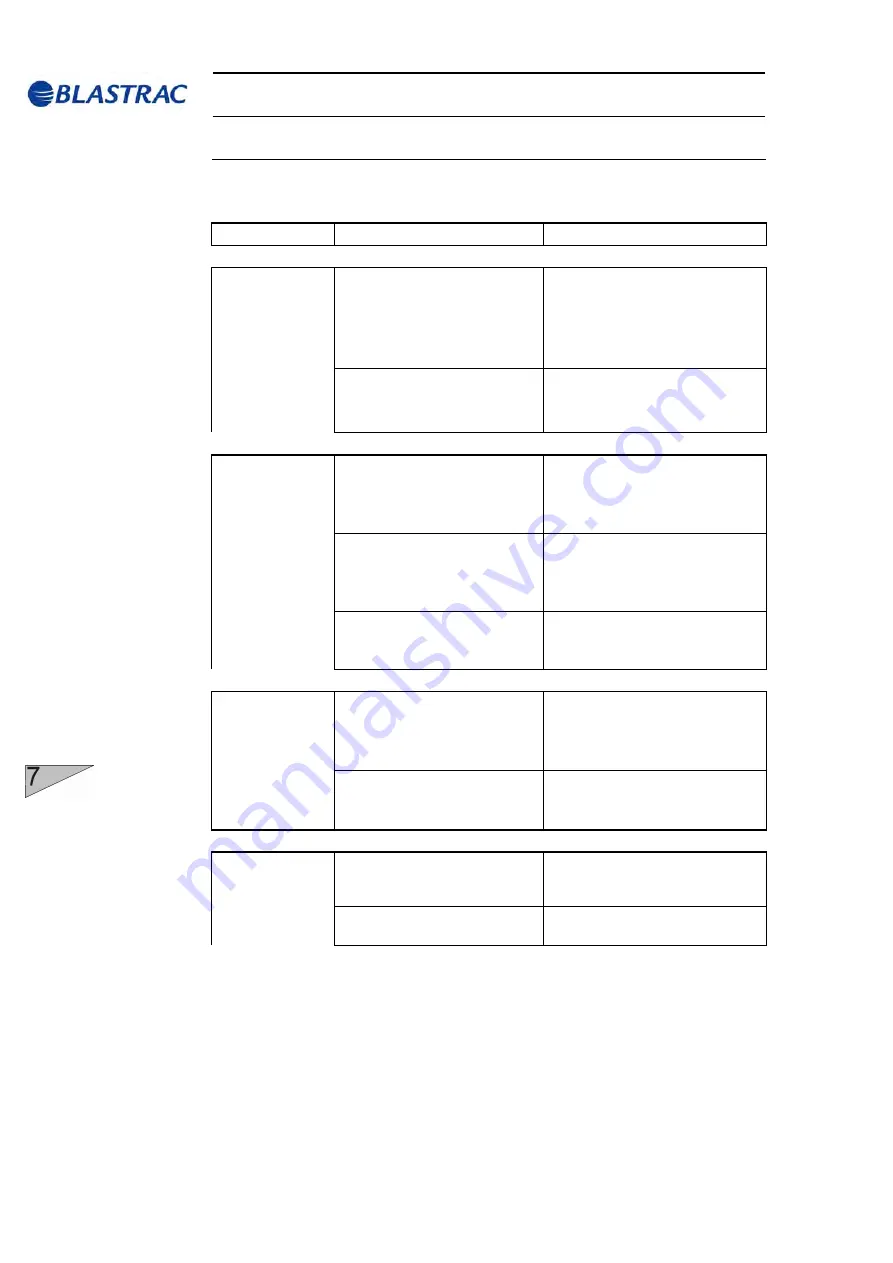

Maintenance

4

Check period

Check

Comments

Daily and prior

to starting work

Check the level of abrasive in

the storage hopper.

Fill the separator equally with the

selected abrasive up to the

bottom of the separator tray. The

magnetic valve must be closed

whilst doing this.

Check the area around the

blast housing for foreign

bodies and dust.

Remove foreign bodies and dust

deposits.

During

operation

Check that the blast wheel

pressure is equal at both

sides.

If necessary re-adjust the

magnetic valves so that they

open equally or refill the hopper

with abrasive.

Watch the level and mixture of

abrasive in the abrasive

storage hopper. The mixture

should be nearly clean.

If necessary regulate the air flow

with the blower throttle.

Check that less than 20% of

the tray surface is covered

with stones or metal parts.

If necessary take out tray and

remove stones or metal parts.

Every 3 hours

Check whether there is any

foreign matter in the hopper.

Remove foreign bodies.

Check the separator parts for

wear and defects.

Remove foreign bodies and dust

deposits in order to prevent the

separator from being blocked.

Weekly

Check the belt tension of the

HTD drives of the blast

motors.

Allow 5 to 7 mm at approx. 10kg

both ways.

Check the belt tension of the V

belts.

Allow 5 to 7 mm at approx. 10kg

both ways.