2-45D

Operating Instructions

Fault diagnosis

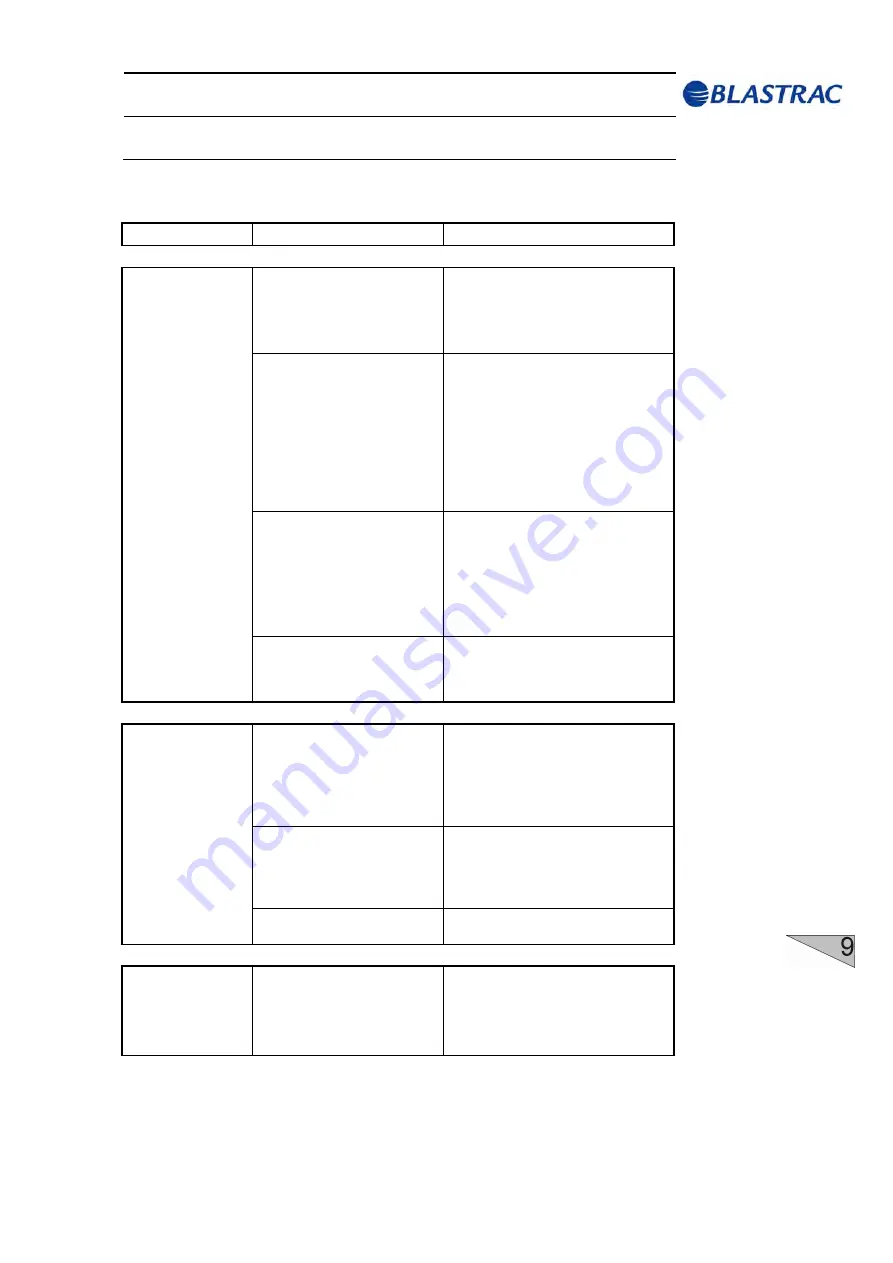

3

Fault diagnosis

Possible cause

Remedy

Reduced or no

blasting

performance

"Shocked blast wheel". At

the start of the blast

process too much abrasive

at once hits the wheel.

Close the magnetic valve and

stop the blast wheel motor. Start

the blast process again and slowly

open the valve.

An indication exceeding the

full load value means

overloading of the hydraulic

system, whereas an

indication below the full load

value shows that there is

not enough abrasive fed to

the blast wheel.

If necessary re-adjust the

magnetic valves or refill the

hopper with abrasive.

The filter unit is not

generating enough airflow.

Check the filter unit (cartridges

and seals). Adjust the airflow so

that the abrasive doesn't drop

dead on the surface, but make

sure that not too much abrasive is

sucked into the filter unit.

Building up of abrasive and

dust in the deflector.

Clean the deflector and the

magnetic drum. Increase the

vacuum of the airflow.

Abrasive loss on

the surface or

escaping

abrasive at the

blast head

Incorrect height adjustment

of the magnetic seals.

Adjust the magnetic seals. Check

the height adjustment (approx. 15

mm) of the blast cleaning

machine.

Poor abrasive quality.

Contact

Blastrac

. Recommended

for most applications

Blastrac

Shot 550 and Shot 460.

Worn blast wheel, impeller

or control cage.

Replace blast wheel, impeller or

control cage.

Contaminated

abrasive

The filter unit is not

generating enough suction

power so that dust remains

in the abrasive.

Check the filter unit (cartridges

and seals).