29

Other maintenance

Check the seals for wear, and replace them at the time when they no longer provide a good seal against dust

emissions from the machine, by this action damage to the surrounding workspace is avoided, and

consequently saves additional charges from the job client.

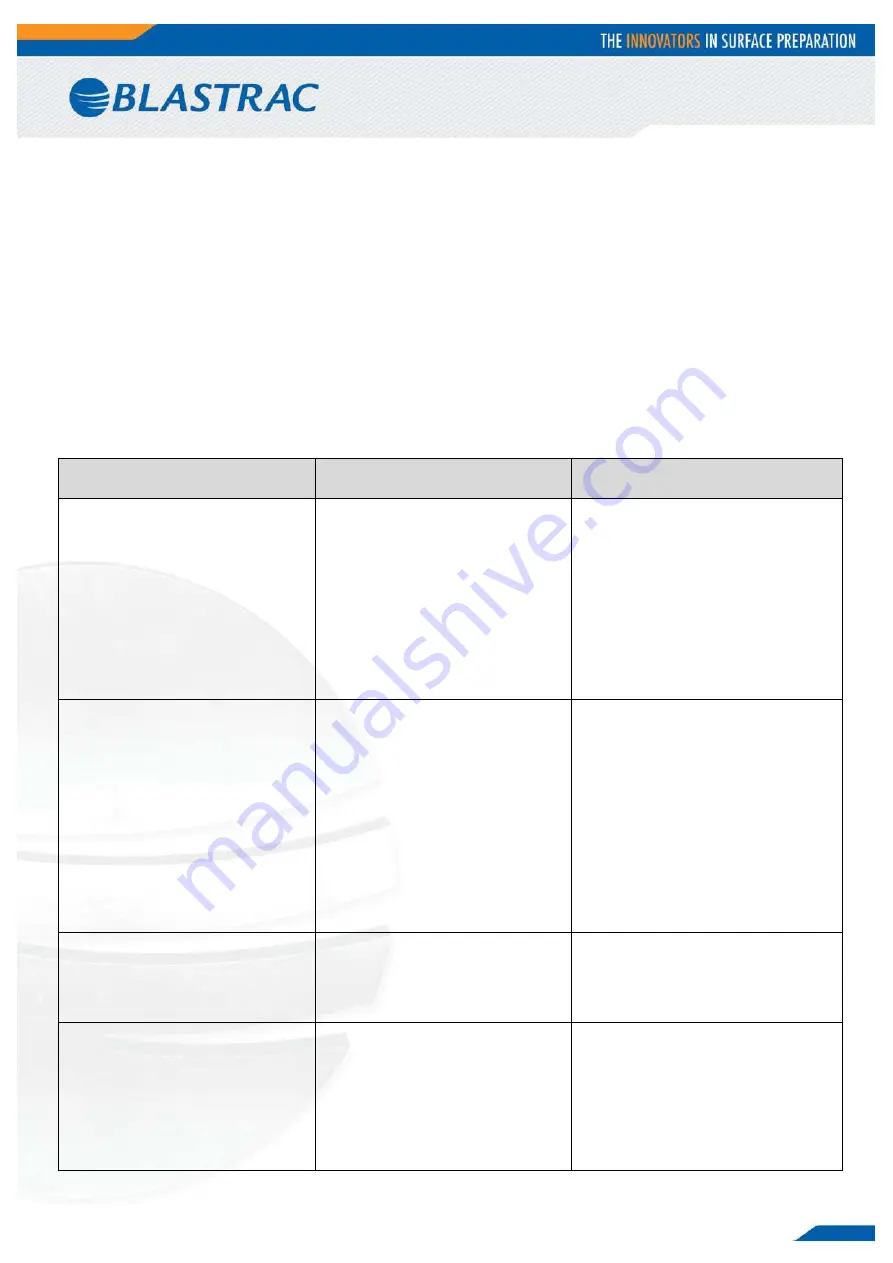

7. Troubleshooting

Prior to any repair works on the equipment or its drives the equipment must be secured

against unintentional switching-on. Disconnect the power supply

.

Fault

Possible cause

Remedy

Unusual noises

To little clearance or wrong

adjustment of the rotating

parts

Too little grease in the

bearing

Silencer assembly defective

Check the alignment and

adjustment of the rotating

parts.

Check screws and all parts for

tight seat.

Lubricate the bearing.

Check and replace if needed.

Too low or no pressure

Check the whole pneumatic

system for leaks.

Dirty airfilter

Check the tension of the

compressors V-belt.

Dirty/too little oil in the

compressor

Fill the leaks or replace the

damaged components.

Clean or replace the air filter

of the compressor.

Adjust the tension of the V-

belt.

Change or refill the oil.

Bad or no filter cleaning

Pressure too low.

Pulse timer / PLC defective

or wrong settings.

See above.

Contact Blastrac.

No suction power

Dirty filter cartridges.

Foreign air leaks in the

dust container.

Clean or replace the filter

cartridges.

Check the alignment or

replace the seal.