5

Application

The 854-DCS is a very powerful mobile dust extractor. This high performance machine is designed and built to

be used exclusively in combination with Blastrac machines. It is equipped with

8 pieces

of specially designed

high quality M-class cartridge filters.

Contact Blastrac B.V. for the correct execution and combinations.

The dust extractor is provided with an air pulse cleaning system which increases the life of the filter cartridges.

This system works by use of pressurized air, built up by a belt driven compressor. The air is led through a

water separator to the pulse system.

The conditioned air then passes a control valve which regulates the system pressure, and then builds up

pressure in the pulse tank. The pressurized air is used to generate a pulse of air which cleans the filters from

the inside. With every pulse of the pulse system, dust and particles are released from the filter surface.

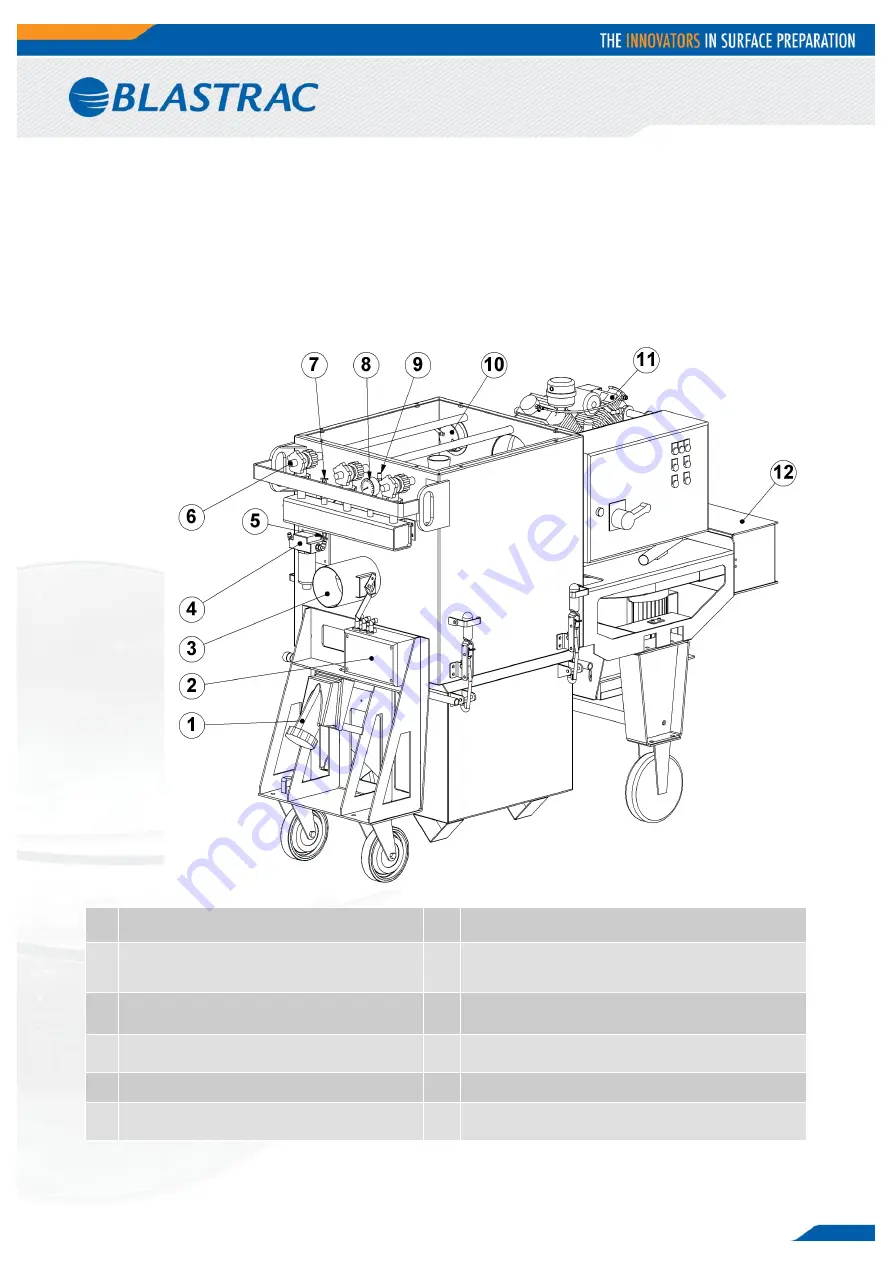

01 Extension lead for Blastrac machine

07 Control valve compressor

02 Timer box

08

Manometer, shows the pressure in the air tank.

The pulse to clean the filters must be given

between 6 - 7 bar.

03 Dust hose connections with butterfly valve 09 Safety valve

04 Water separator with manual drain

10 Pressure difference gauge, replace filters when

indicating 15cm.H2O

05 Drain cock

11 Compressor

06 Membrane valve

12 Silencer