12

10

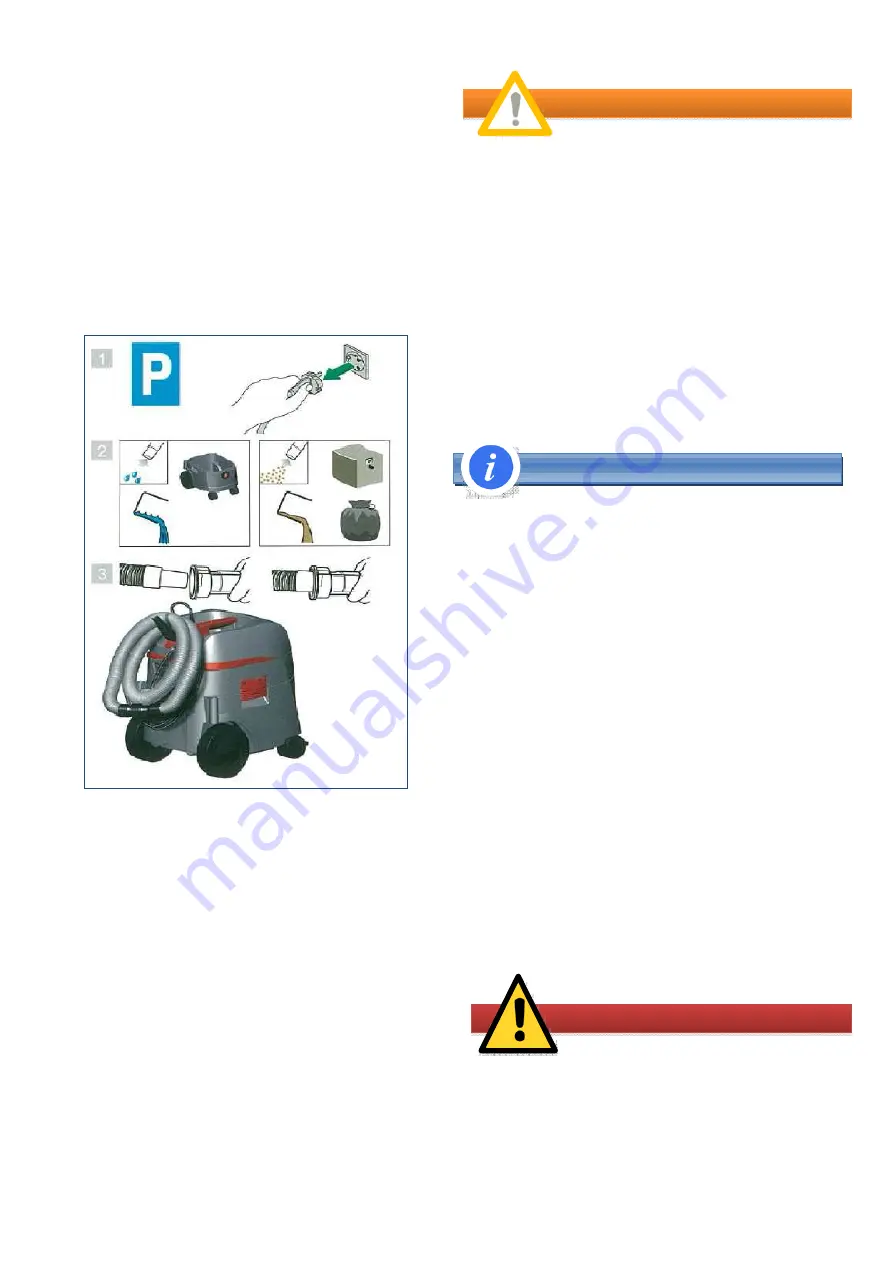

Transport

▷▷

Insert the closing plug of the vacuum cleaner

into the suction aperture.

▷▷

The motor head must be securely fixed to the

container (close the latches).

▷▷

Place the accessories in a suitable plastic bag

and seal the plastic bag or place it in the tool

storage compartment.

▷▷

Plug the ends of the suction hose into each

other.(3)

▷▷

Place the hose around the vacuum cleaner and

clamp onto the handle.

Caution

Precautionary measures with vacuum

cleaners class H and M

The outside of the vacuum cleaner should be

cleaned and wiped down or should be treated with

a sealing agent before being removed from the

dangerous area. All parts of the vacuum cleaner

must be considered to be contaminated when they

are removed from the danger area and suitable

handling must be used to prevent dust distribution.

Contaminated items

When carrying out maintenance or repair work, all

contaminated items which have not been

adequately cleaned must be disposed of. Such

items must be disposed of in impermeable bags in

accordance with the applicable regulations

concerning the disposal of such waste.

Information

Testing the effectiveness of the vacuum

cleaner

NOTE: In addition, the effectiveness of the

vacuum cleaner class H must be checked at least

once a year. There must be an adequate air

exchange rate L in the room if the

exhaust air returns to the room. Further

information can be taken from your national

regulations. If the suction of the vacuum cleaner

reduces and the cleaning procedure of the folding

filter cassettes increases, the suction performance

is not adequate (provided that the container is

empty and the fleece filter bag has been replaced)

then it is necessary to replace the folding filter

cassettes.

11

Maintenance

-Switch the vacuum cleaner off and pull out the

mains plug before any maintenance work.

For maintenance by the user, the vacuum cleaner

must be

-

dismantled,

-

cleaned and

-

maintained,

as far as possible without creating any danger to

the maintenance personnel or other.

Precautionary measures

Suitable precautionary measures include

-

Cleaning before dismantling,

-

Provide local filtered positive ventilation where

the vacuumcleaner is to be dismantled,

-

Clean the maintenance area and

-

suitable personal protection equipment.

11.1

Cleaning

Acids, alkalis and solvents can corrode the vacuum

cleaner parts.

▷▷

Clean the container and accessories with water.

▷▷

Wipe the top section with a damp cloth.

▷▷

Allow the container and accessories to dry.

11.2

Repair

DANGER! – WARNING!

▶▶

Inappropriately repaired vacuum cleaners

present a danger to the operator.

▶▶

Have repairs carried out by specialists, e. g.

customer service. Use only genuine spare parts.

Summary of Contents for BDC-1114PH CA ASBESTOS

Page 1: ...Original Operating Instructions VERSION 1 9 BDC 1114PM BDC 1114PH BDC 1114PH CA ASBESTOS...

Page 17: ...17 competent person Other comments...

Page 18: ...SERVICE MANUAL BDC 1114 VERSION 1 5...

Page 19: ...Index 1 Assembly plans Spare parts 04 Contact 07 2...

Page 20: ...3 1 Assembly plans Spare parts...

Page 21: ...Operating Unit 4...

Page 23: ...6 Suction unit...