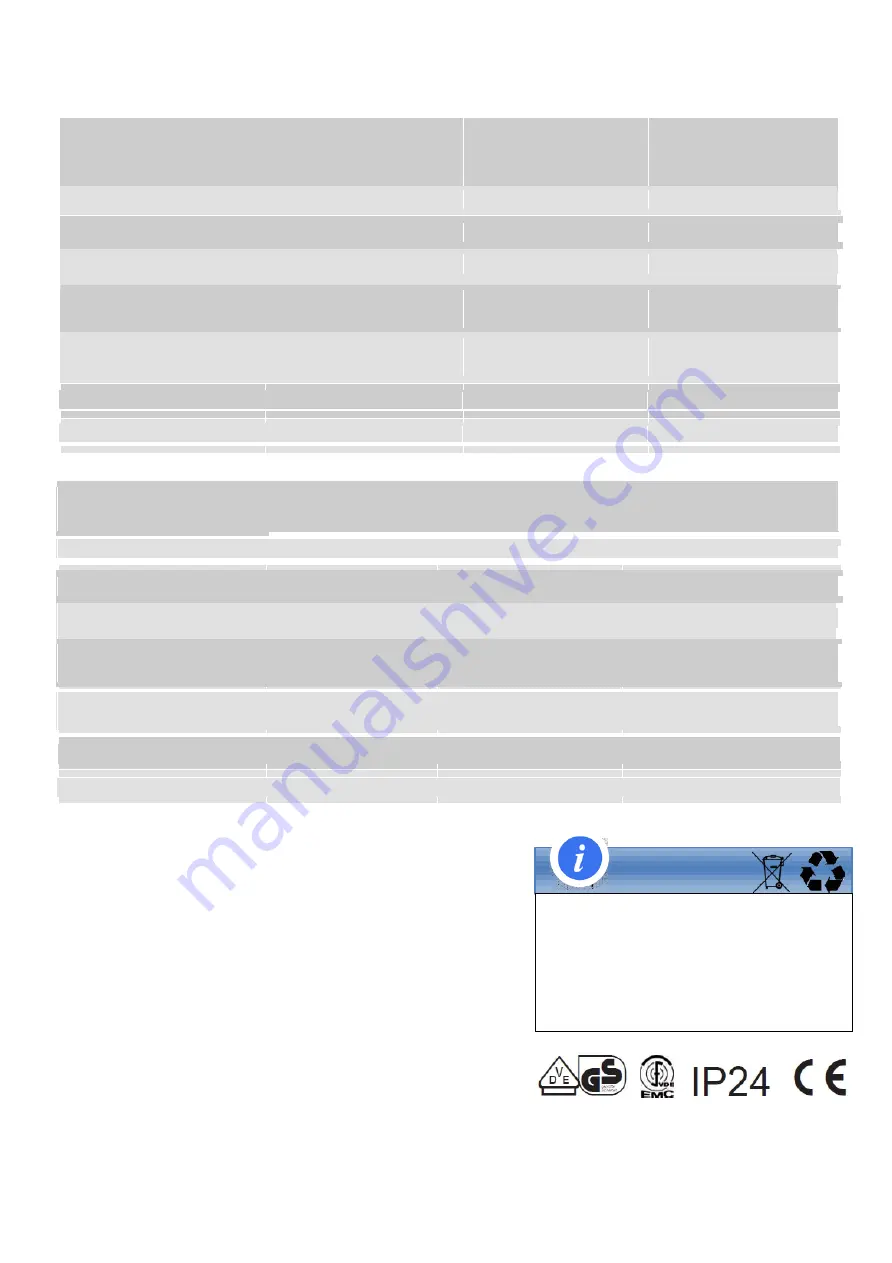

14 Technical Data

BDC-1114PM

BDC-1114PH

110V-50Hz

BDC-1114PM

BDC-1114PH

120V-60Hz

BDC-1114PM

BDC-1114PH

230V

Power consumption

1,2 kW

1,2 kW

1,2 kW

Max. power

1,4 kW

1,4 kW

1,4 kW

Electrical connection /

frequency

220-240V / 50-60 Hz

100-120V / 50 Hz

100-120V / 60 Hz

Air flow at hose end

Air flow at blower

140 m3/hr/SE

230 m3/hr/SE

140 m3/hr/SE

230 m3/hr/SE

140 m3/hr/SE

230 m3/hr/SE

Under pressure at hose end

Under pressure at blower

225 hPa/SE

259 hPa/SE

225 hPa/SE

259 hPa/SE

225 hPa/SE

259 hPa/SE

Weight

17.1 kg

17.1 kg

17.1 kg

Noise level

Up to 69.5 dB(A)

Up to 69.5 dB(A)

Up to 69.5 dB(A)

BDC-1114

PH CA ASBESTOS

230V

BDC-1114

PH CA ASBESTOS

110V-50Hz

BDC-1114

PH CA ASBESTOS

120V-60Hz

Power consumption

1,2 kW

1,2 kW

1,2 kW

Max. power

1,2 kW

1,2 kW

1,2 kW

Electrical connection /

frequency

220-240V / 50-60 Hz

100-120V / 50 Hz

100-120V / 60 Hz

Air flow at hose end

Air flow at blower

140 m3/hr/SE

230 m3/hr/SE

140 m3/hr/SE

230 m3/hr/SE

140 m3/hr/SE

230 m3/hr/SE

Under pressure at hose end

Under pressure at blower

225 hPa/SE

259 hPa/SE

225 hPa/SE

259 hPa/SE

225 hPa/SE

259 hPa/SE

Weight

17.1 kg

17.1 kg

17.1 kg

Noise level

Up to 69.5 dB(A)

Up to 69.5 dB(A)

Up to 69.5 dB(A)

Dimensions for all models (LxBxH): 53 cm x 40 cm x 55 cm.

Connection line on vacuum cleaners with plug socket:

H07RN-F 3x1,5

15 Tests and approvals

Electro-technical tests must be carried out in accordance

With the accident prevention regulations (BGV A3) and in

Accordance with DIN VDE 0701 Part 1 and Part 3.

These tests are required in accordance with DIN VDE 0702

at regular intervals and after repair or modification. A dust-

technical check must be carried out at least once a year, or

more frequently as may be specified by national requirements,

by the manufacturer or a trained person, e. g. for damage

to the filter, dust-tightness of the vacuum cleaner, function

of the monitoring equipment.

The vacuum cleaners are successfully tested in accordance

with IEC/EN 60335–2–69 including annex AA.

Information

Old equipment contains valuable materials

which are designed for re-processing.

The vacuum cleaners must not be

thrown away in the normal household

waste, but should be disposed of at a

suitable proper collection system, e. g. via

your communal disposal location.

14

Summary of Contents for BDC-1114PH CA ASBESTOS

Page 1: ...Original Operating Instructions VERSION 1 9 BDC 1114PM BDC 1114PH BDC 1114PH CA ASBESTOS...

Page 17: ...17 competent person Other comments...

Page 18: ...SERVICE MANUAL BDC 1114 VERSION 1 5...

Page 19: ...Index 1 Assembly plans Spare parts 04 Contact 07 2...

Page 20: ...3 1 Assembly plans Spare parts...

Page 21: ...Operating Unit 4...

Page 23: ...6 Suction unit...