ADJUSTING THE BRAKES

Small incremental brake adjustment :

Free play at the handlebar lever is

effected by turning the knurled end on the

cable adjustor. This will allow the lever to

be set at the nominal to ¼ inch of free

lever movement.

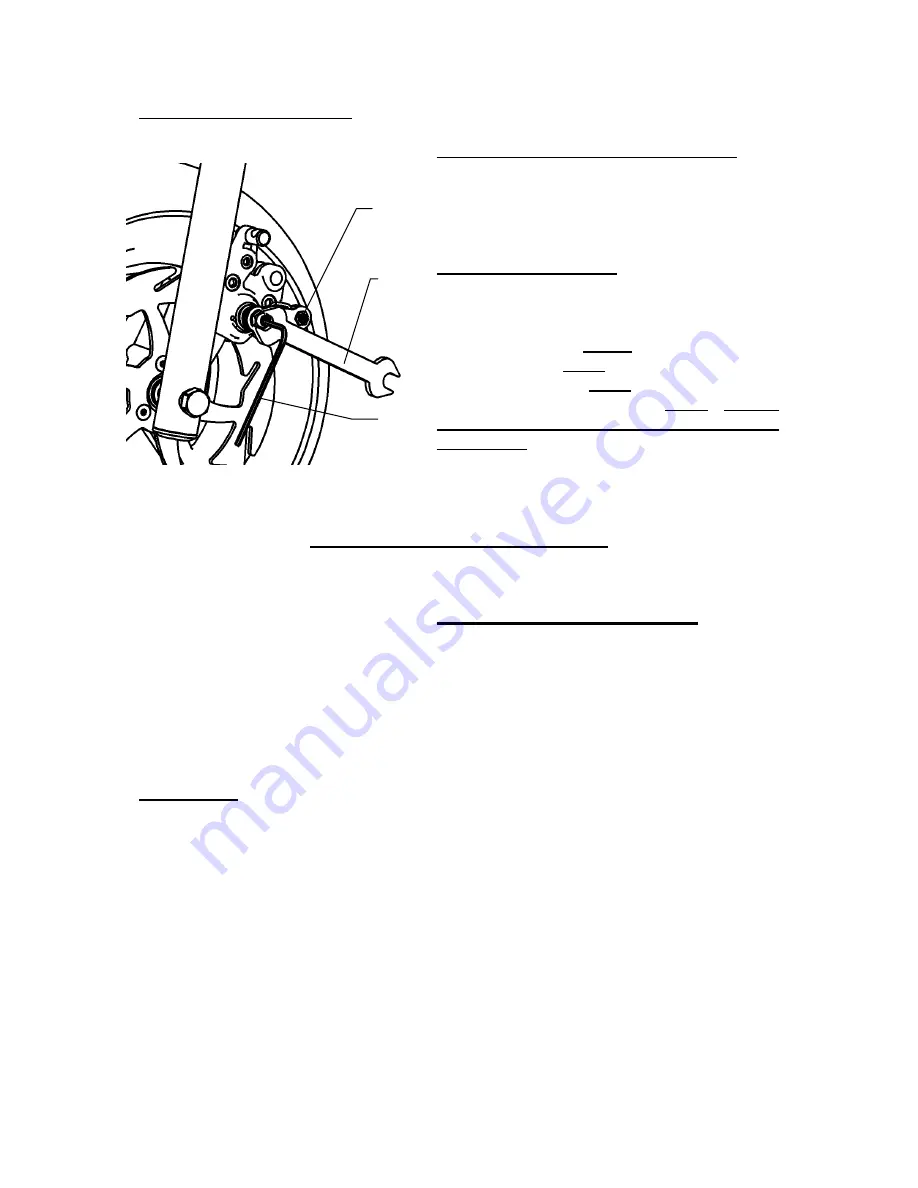

Basic brake adjusting:

Screw in the knurled cable adjustor at the

brake lever so the cable is in it’s most

slack starting position.. At the caliper,

loosen the nut, No. 3 and tighten the

adjustable bolt No. 4, so the wheel cannot

turn. Back off bolt No. 4 about ¼ to ½ of a

turn and fix it with lock nut No. 3

. Do not

use the cable retainer No. 5 for adjusting

the brakes!

BRAKE PADS REPLACEMENT: FIG.7

At first, screw in the knurled cable adjustor at the brake lever on the

handlebars. Unscrew two screws M5-914.003.01 that hold the brake body on

fork and shift out the brake backwards. Take out from brake body two distance

columns and two columns with coil. Do not loosen the cable retainer! Unscrew

screws M6-914.010.01 and separate both halves of brake body and shift the

worn-out brake plates out. Into the part with operating mechanism slide the

brake plate with pin bore and unscrew completely the adjusting screw. Force

on carefully the brake plate into the opposite piece. Before reassembly clean

the whole brake. Assembly follows in reverse sequence.

Carburettor:

After the engine has been run in, sometimes the carburettor has to be adjusted.

We suggest you have this operation done by a qualified service shop. For

those who believe they are able to do it themselves, this is the procedure you

must follow:

The setting is done with the rear wheel lifted and the engine running. Let the

engine run at full speed by turning the gas grip and then by turning the

adjusting screw (Fig. 1 – adjusting screw “E”). Set (tune) the engine to the

highest possible speed and then turn the gas grip back.

Set idling speed to between 3000 and 3100 rpm by turning screw “D” – see Fig.

1. The carburettor is a very fine piece of equipment and must be kept clean.

5

3

4

5

Summary of Contents for Blatino

Page 1: ...USER S MANUAL SCOOTER WITH AUXILIARY ENGINE...

Page 2: ......

Page 10: ...7 FIG 4...

Page 11: ...8...

Page 12: ...9...

Page 13: ...10 AIR FILTER COMPL CARBURETOR WYK 42...

Page 14: ...11 916 072 02 512 055 00 FRONT BRAKE COMPLETE 512 056 00 REAR BRAKE COMPLETE 916 072 02...

Page 18: ......

Page 19: ......

Page 20: ...COPYRIGHT BLATA 2007 C...