2

8

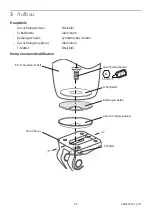

1.

With the socket plate inside the socket, pass the threaded Alignment Bolt through the hole

in the end of the socket.

2.

On the outside of the socket, and working from inside the socket, pass the Alignment

Coupling and Friction Disk over the bolt followed by any spacers used, ensuring that the

friction surface of the spacer is distal and touches the upper surface of the knee.

3.

Pass the Alignment Bolt through the centre of the single bolt hole in the upper surface of

the knee.

4.

Invert the knee and with the socket plate and bolt supported, pass the washer over the

central bolt followed by the nut, ensuring that the raised central lip on the nut engages

with the mating surface of the washer.

5.

Apply Loctite 222 to the thread of the Alignment Bolt. Adjust and align the limb according

to the Instructions For Use supplied with the knee, then tighten the Alignment Nut and Bolt

to 35 Nm.

6.

Seal with silicone for waterproofing.

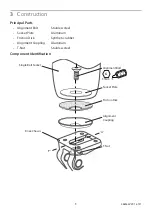

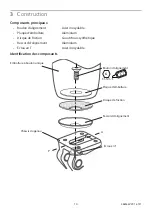

Typical build (ESK+ shown)

Symptom

Solution

A recurring noise occurs

between the socket and the

knee.

Ensure that the socket interface has been correctly formed and

is the correct thickness. The Alignment Nut must be tightened.

Apply Loctite and tighten to the correct torque setting.

The adapter moves out of

position.

User must not use the device until adjusted, repaired or

replaced.

The instructions in this section are for practitioner use only.

Position as close as possible to the build line.

Note… This kit is designed for use with sockets that are 5–6 mm thick at the distal end and are

manufactured using Blatchford socket formers.

Alignment Coupling Assembly

T-Nut

Front Stop

56 mm

Set Screws (x2)

LOCTITE

222

Flex knee to fit parts

as shown. Ensure

Alignment Coupling/

Socket does not clash

with shin/cylinder

components when knee

is fully flexed.

2 mm A/F - Mercury

3 mm A/F - ESK+ 4 Bolt

1.5 mm A/F - KX06V2/KX07

Socket

5–6 mm

7

Fitting Advice

938265PK1/1-0121

Summary of Contents for 239032

Page 83: ...83 938265PK1 1 0121...