www.blaubergventilatoren.de

11

VENTO V50-1 / V50-1 S / V50-1 Pro / V50-1 S Pro

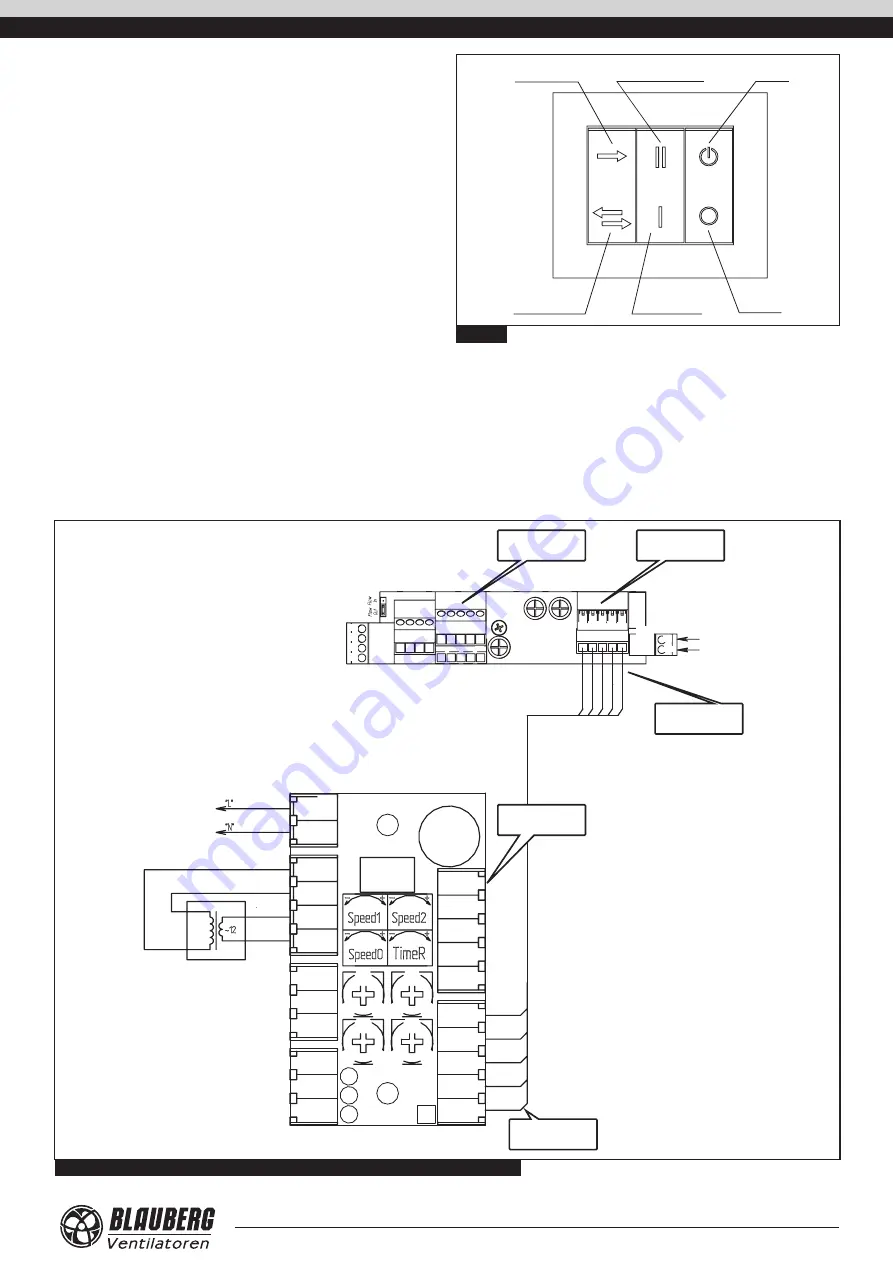

All electric connection to the control unit and the ventilator are performed

with the socket connectors (detachable terminal blocks) for mounting and

servicing facilitation. Each mating part of the socket connector has colour

marking in compliance with marking on the circuit board to ensure correct

and quick electric installation.

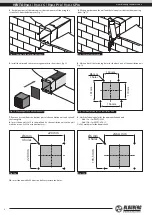

The control panel SEA is used to set one of four operation mode of the

unit, Fig. 23:

1. Ventilation mode (air extract / air supply)* at the first speed with air

flow 26 m

3

/h.

2. Ventilation mode (air extract / air supply)* at the second speed with air

capacity 53 m

3

/h.

3. Reversible (regeneration) operation at the first speed with air flow 26 m

3

/h.

The unit changes air flow direction every 70 seconds.

* - air flow direction depends on position of the jumper JMP1 on the

circuit board. The jumper is set to supply mode by default, Fig. 24.

Unit on

Unit off

First speed

mode

Reversible

operation mode

Second speed mode

Extract/supply mode*

Fig. 23

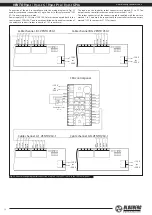

The total wiring diagram for connection to the control panel SEA is shown

in Fig. 24.

Two control channels are used to connect V50-1 to the control panel SEA.

Such design solution provides flexible connection of several units.

The impeller rotation direction at start of the regeneration mode or in

ventilation mode is determined by positioning the jumper JMP1 on the

ventilation unit circuit board. The jumper positioned in «Flow In» position sets

the unit to supply mode and the jumper positioned in «Flow Out» position

sets the unit to extract mode.

The VENTO V50-1 is connected to the control panel SEA with a five-wire

cable. The wire colour marking corresponds to the supplied cable. The

minimum conductor cross section is 0.25 mm

2

(23 AWG).

Type and power of the step-down transformer T1 must be in compliance

with the parameters in the table 2. Separate power supply (230 V / 50 Hz or

120 V / 60 Hz) must be connected both to the control unit SEA (SEA-T) and

to the ventilation unit to enable actuation of the automatic shutters (socket

connectors 31-32 in each case).

Fig. 24. General wiring diagram for connection of Vento V50-1 unit to a single SEA control panel

31

32

33

34

35

36

11

12

13

14

15

11

12

13

14

15

1

2

3

4

5

1

2

3

4

5

31

32

33

34

35

36

37

38

39

40

ÕÒ

3

25

21 22 23 24

15

14

13

12

11

5

1

2

3 4

1

2

3

4

5

31

32

33

34

35

36

37

38

39

40

ÕÒ

3

25

21 22 23 24

15

14

13

12

11

5

1

2

3 4

L

N

5

4

3

2

1

SEA control panel

VENTO V50-1

JMP1

Marking "1-5" on the

connecting cable socket

connector

Marking "11-15" on the

controller socket

connector

~120 V

or

~230 V

~120 V

or

~230 V

Marking "1-5" on the

connecting cable

socket connector

Marking "11-15" on the

controller socket

connector

Marking "21-25" on the

controller socket

connector

~120 V

or

~230 V

gre

y

br

own

yello

w

gr

een

whit

e

grey

brown

yellow

green

white

white

white

red

red

Transformer 12 W

АТ-12