www.blaubergventilatoren.de

15

VENTO V50-1 / V50-1 S / V50-1 Pro / V50-1 S Pro

Fault

Possible reasons

Fault handling

The fan does not start

when the unit is on.

No power supply.

•

Make sure of correct power supply, otherwise troubleshoot

the connection error.

Jammed motor, soiled impeller blades.

•

Turn the unit off.

•

Troubleshoot the motor jam and the impeller clogging.

Clean the blades.

•

Restart the unit.

Automatic switch tripping

during the unit start.

Short circuit in power grid as a result of short circuit.

•

Turn the unit off.

•

Contact the seller.

Low air flow.

Low set fan speed.

•

Set higher speed.

The filter, the fan or the regenerator are soiled.

•

Clean or replace the filter.

•

Clean the fan and the regenerator.

Noise, vibration.

The impeller is soiled.

•

Clean the impeller.

Loose screw connection of the unit casing or the outer

ventilation hood.

•

Tighten the screws of the unit or the outer ventilation

hood.

TROUBLESHOOTING

The unit technical maintenance consists in the periodic cleaning of the

unit surfaces and cleaning or replacement of the filters. Remove dust

with a soft brush, cloth or compressed air. Do not use water, abrasive

detergents, solvents, sharp objects.

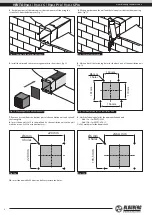

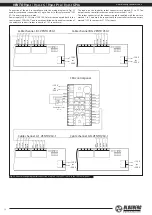

1. Fan maintenance (once a year).

•

Remove the screw in the bottom part of the fan grille, remove and

clean the grille.

•

Disconnect the wires from the ventilation unit by using the

connectors.

•

Remove the four screws and take off the ventilation unit.

•

Clean the impeller blade.

2. Regenerator and filter maintenance (4 times a year).

•

Take off the ventilation unit. Pull the cord to remove the regenerator

and the filter from the air duct. Do not let the regenerator fall down.

•

Clean the filter as often as required, but at least once in three

months. To clean the filter flush it under running water or use a

vacuum cleaner. Let the filter dry and install the dry filter inside the

air duct. Contact a local distributor for the filters stated above in the

section «Technical data».

•

Even regular filter maintenance may not completely prevent the

dust ingress into the regenerating unit. Clean the regenerator with

a vacuum cleaner at least once a year.

3. Outer ventilation hood maintenance (once a year).

The outer ventilation hood may get clogged with leaves and other objects

that reduce the unit air capacity.

Check the outer ventilation hood twice a year and clean it as often as

required.

Cleaning of the outer ventilation hood:

•

remove the front part of the outer ventilation hood:

•

clean the outer ventilation hood and the air duct.

WARNING!

Disconnect the unit from power mains prior to maintenance operations!

MAINTENANCE