www.blaubergventilatoren.de

3

VENTO V50-1 / V50-1 S / V50-1 Pro / V50-1 S Pro

BLAUBERG Ventilatoren GmbH is happy to offer your attention the new

reversible ventilation heat recovery single-room unit

VENTO V50-1

.

INTRODUCTION

The present operation manual contains a technical description, technical

data sheets, operation and mounting guidelines, safety precautions and

warnings for safe and correct operation of the unit.

GENERAL

The single-room ventilation unit is designed for efficient energy saving

supply and exhaust ventilation of flats, houses, cottages and other small

premises.

The heat recovery technology is used to minimize ventilation heat losses.

The ventilation unit is equipped with a high-tech ceramic energy

regenerator that provides extract air heat recovery for warming up of filtered

supply air. The heat recovery efficiency of the energy regenerator is up to

90%.

The ventilation unit is designed for indoor application with the ambient

temperature ranging from -20 °C up to +50 °C and relative humidity up to

80%.

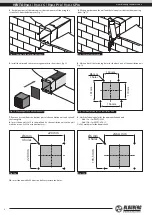

The unit is designed for external through-the-wall installation. The unit is

designed for continuous operation always connected to power mains.

The unit is allowed for operation only after its final mounting that includes

installation of protecting devices in compliance with DIN EN ISO 13875 (DIN

EN ISO 12100) as well as other construction safety equipment.

The unit design is regularly improved, so some models may slightly differ

from those ones described in this operation manual.

SAFETY RULES

The appliance complies with the requirements according to the EU norms

and directives, to the relevant EU-Low Voltage Equipment Directives, EU-

Directives on Electromagnetic Compatibility.

Disconnect the appliance from power mains before any operations

related to the electrical connections, servicing and repair operations.

All mounting and servicing operations are allowed for duly qualified

electricians with valid electrical work permit for electric operations at the

units up to 1000 V after careful study of the present operation manual.

The appliance requires grounding!

Please follow the safety regulations and working instructions (DIN EN 50

110, IEC 364).

Make sure the impeller and the casing are not damaged before

connecting the appliance to power mains. The casing internals must be free

of any foreign objects which can damage the impeller blades.

Disconnect the appliance from power mains prior to any operations

related to the appliance servicing and repair works. Make sure the rotating

parts have come to a full stop.

Misuse of the appliance or any unauthorized modification are not allowed.

The appliance is designed for connection to AC single-phase power

mains, see «Technical Data». The appliance is rated for permanent operation

during non-stop power supply.

Take steps to prevent ingress of smoke, carbon monoxide and other

combustion products into the room through open chimney flues or other

fire-protection devices. Sufficient air supply must be provided for proper

combustion and exhaust of gases through the chimney of fuel burning

equipment to prevent back drafting. The maximum permitted pressure

difference per living units is 4 Pa.

The transported air must not contain any dust or other solid impurities,

sticky substances or fibrous materials.

The appliance is not designed for use in an inflammable and explosive

medium.

Do not close or block the intake or exhaust vent of the appliance not to

disturb the normal air passage.

Do not sit on the appliance and do not put objects on the appliance.

In case of unusual sounds, smoke disconnect the appliance from power

supply and contact the service centre.

Follow the operation manual guidelines to ensure trouble-free operation

and long service life of the appliance.

Hazardous parts access and water ingress protection standard IP24.

TRANSPORTATION AND STORAGE RULES

Transportation of the appliance is allowed by any vehicle provided the

appliance is transported in the original package and is protected against

weather and mechanical damages.

Use hoist machinery for handling and transportation to prevent

possible mechanical damages of the appliance. Fulfil the requirements for

transportation of the specified cargo type during cargo-handling operations.

Store the appliance in a dry and cool place in the original packing.

The storage environment must not be subjected to any aggressive and/

or chemical evaporations, admixtures, foreign objects that may provoke

corrosion and damage connection tightness.

Store the appliance in an environment with minimized risk of mechanical

damages, temperature and humidity fluctuations.

Do not expose the appliance to the temperatures below +5 °C and above

+40 °C .

Connection to power mains is allowed after the appliance has been kept

indoor for minimum two hours.

MANUFACTURER’S WARRANTY

The appliance complies with the requirements according to the EU norms

and directives, to the relevant EU-Low Voltage Equipment Directives, EU-

Directives on Electromagnetic Compatibility.

We hereby declare that the following product complies with the essential

protection requirements of Electromagnetic Council Directive 2004/108/

EC, 89/336/EEC and Low Voltage Directive 2006/95/EC, 73/23/EEC and

CE-marking Directive 93/68/EEC on the approximation of the laws of the

Member States relating to electromagnetic compatibility.

The manufacturer hereby warrants normal operation of the appliance

over the period of 2 years from the retail sale date provided observance of

the installation and operation regulations.

In case of failure due to manufacturing fault during the warranty period

the consumer has the right for a replacement appliance.

If case of no confirmation of the sale date, the warranty period shall be

calculated from the manufacturing date.

The replacement is offered by the Seller.

The manufacturer shall not be liable for any damage resulting from any

misuse of or gross mechanical interference with the appliance.

Fulfil the operation manual requirements to ensure a trouble-free and

long service life of the appliance.

WARNING

Do not dispose in domestic waste.

The appliance contains in part mate-

rial that can be recycled and in part

substances that should not end up as domestic

waste.

Dispose of the appliance once it has reached the

end of its working life according to the regulations

applicable for your country.

ATTENTION

The product is not allowed for use by

children and persons with reduced physi-

cal, mental or sensory capacities, without proper

practical experience or expertise, unless they are

controlled or instructed on the product operation

by the person(s) responsible for their safety. Super-

vise the children and do not let them play with the

product.

!