www.blaubergventilatoren.de

25

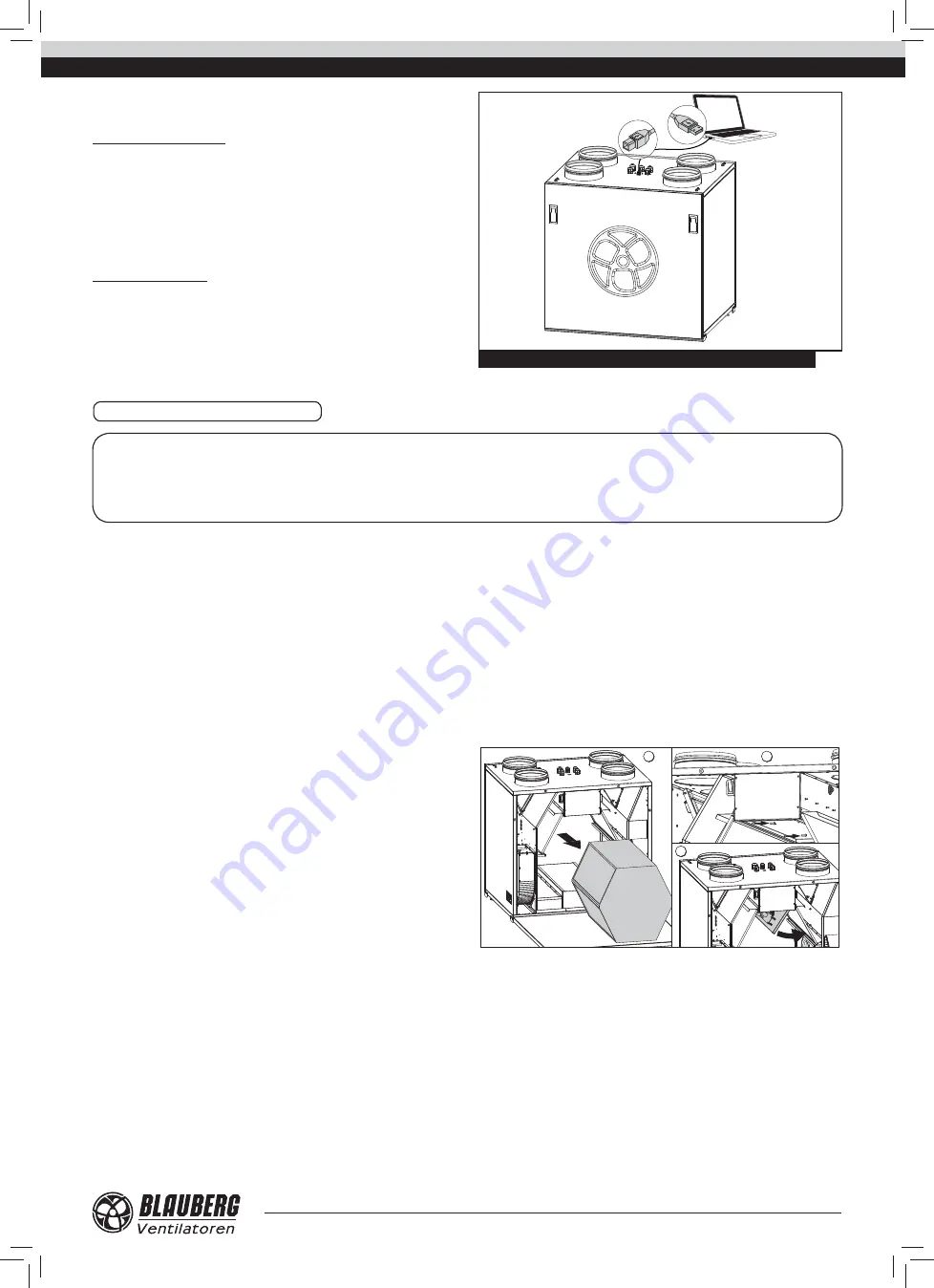

KOMFORT EC S/SB

The

KOMFORT EC S S15 / KOMFORT EC SB S15

units are equipped with

a USB connector (Type B) and can be connected to a PC for confi guring the

advanced settings in a special software (available for download on the website

eng.blaubergventilatoren.de).

To work with the pre-installed software connect the unit to a laptop or

to a PC via a USB cable with the Type A and Type B contact sockets. The USB

cable is not included in the delivery set. The software enables editing the unit

parameters (see Table 10).

The list of the adjustable parameters can be expanded in new versions of

the software.

Setting, troubleshooting and upgrading of the software version is made by

the service technician.

The software is available for downloading on our website:

blaubergventilatoren.de.

USB Type B

USB Type A

Fig. 21. Connection of a PC to the units with the S15 control panel

TECHNICAL MAINTENANCE

Regular technical supervision and maintenance of the unit are required to

ensure the product long service life and non-stop operation.

Disconnect the unit from power supply prior to any maintenance

operations.

WARNING! Consider the unit sharp edges! Fulfi l maintenance

operations in work gloves!

WARNING

Cut power supply to the unit off by turning the automatic electric switch QF to OFF position prior to

any maintenance operations.

Take steps to prevent activation of the automatic switch before fi nishing all the operations.

The unit must undergo technical maintenance 3 to 4 times a year.

The unit technical maintenance includes regular cleaning and other works:

1. Filter maintenance (3-4 times per year).

Dirty fi lters increase air resistance in the system and reduce supply air

volume. The fi lters require cleaning not less than 3-4 times per year. Vacuum

cleaning is allowed. After two consecutive cleanings fi lters must be replaced.

For new fi lters contact the Seller.

2. Heat exchanger maintenance (once a year).

Some dust may accumulate on the heat exchanger block even in case of

regular maintenance of the fi lters. To maintain the high heat recovery effi

ciency,

regular cleaning is required. To clean the heat exchanger pull it out, fl ush the

heat exchanger with warm detergent solution. After cleaning install the dry

heat exchanger back to the unit.

3. Fan maintenance (once a year).

Even in case of regular maintenance of the fi lters, some dust may

accumulate inside the fans and reduce the fan performance and supply air fl ow.

Clean the fans with a soft brush or cloth. Do not use water, aggressive

solvents or sharp objects as they may damage the impeller.

4. Technical maintenance of condensate drainage system (once a year).

The drain pipes may get clogged with the extracted particles. Pour some

water inside the drain pan to check the pipe for clogging. Clean the U-trap and

the drain pipe if required.

5. Technical maintenance of an air duct system (every 5 years).

Even regular fulfi lling of all the prescribed above maintenance operations

may not completely prevent dirt accumulation in the air ducts which reduces

the unit capacity. Duct maintenance means regular cleaning or replacement.

6. Control unit maintenance (if necessary).

The control unit maintenance must be performed by an expert qualifi ed for

unassisted operations with electrical installations with the voltage up to 1000 V

after careful reading of the user’s manual.

Access to the control board of the control unit:

1

2

3