www.blaubergventilatoren.de

KoMFort Erv d

7

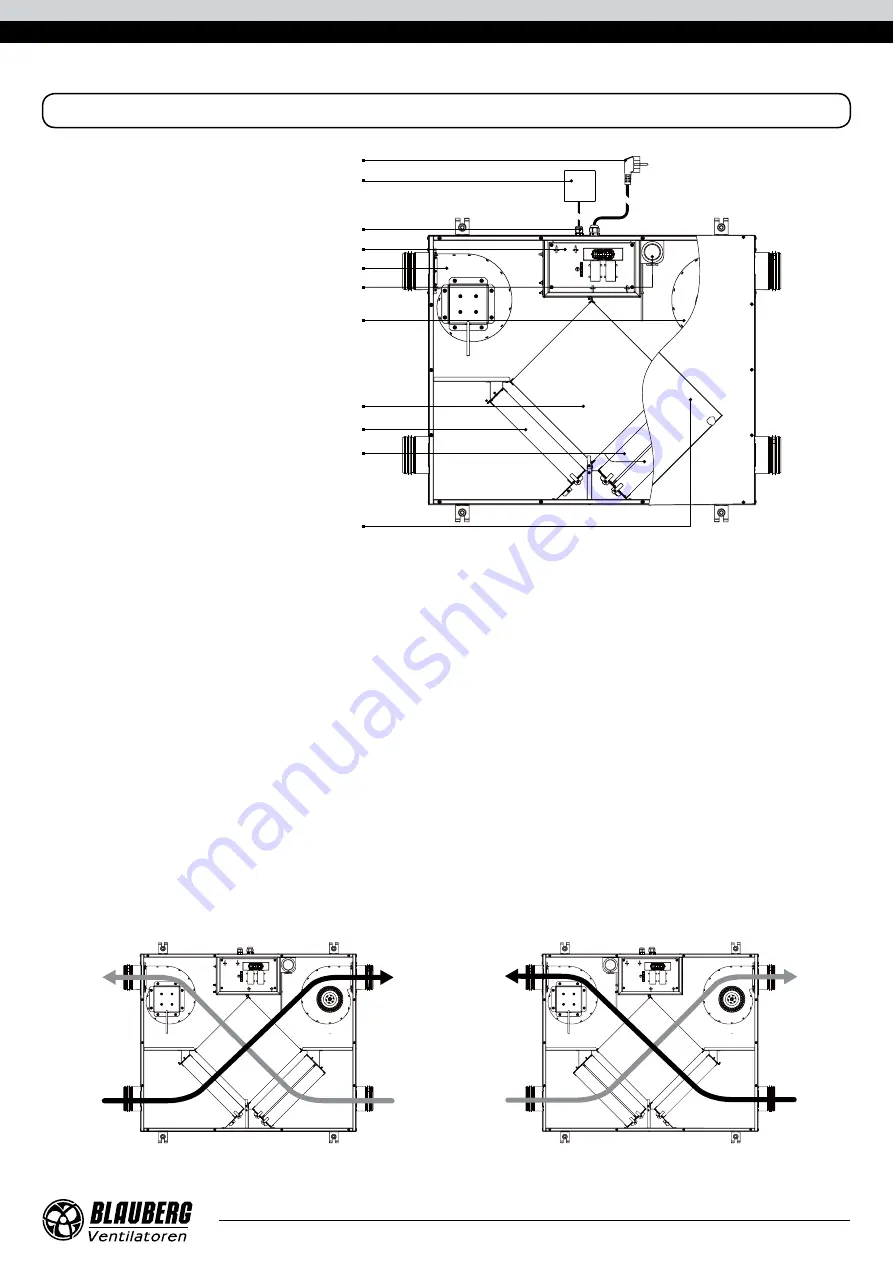

DESIGN AND OPERATING PRINCIPLE

Supply fan

Extract fan

Extract air filter

Control unit

Thermostat for heat exchanger freeze protection

Cable glands

Cross-flow heat exchanger

Supply air filter

Controller

Power cord with a plug

Inspection hatch for filter and heat

exchanger maintenance

The service side of the unit is equipped with a detachable inspection hatch on manual bolts for filter and heat exchanger cleaning and

replacement operations. The plate enthalpy cross-flow heat exchanger is made of polymerized cellulose.

The control unit is positioned inside the unit casing . The power cable and grounding cables are connected to the control unit via the

cable gland located at the side of the unit. The unit is equipped with a controller and a power cord with a Euro Plug XP.

Warm stale extract air from the room flows into the unit, where it is filtered by the extract filter, then air flows through the heat

exchanger and is exhausted outside by the extract fan. Cold fresh air from the outside flows into the unit, where it is cleaned by the

supply filter. Then the air flows through the heat exchanger and is directed to the room with the supply fan.

Supply air is heated in the heat exchanger by transferring the heat energy of warm and humid extract air to the cold fresh air.

The air flows are fully separated while flowing through the heat exchanger. Heat recovery minimizes heat losses, which reduces the

cost of space heating in the cold season. The enthalpy heat exchanger provides both heat and humidity recovery.

In warm seasons the heat exchanger operates to cool down and dehumidify the supply air. In cold seasons the heat exchanger

operates to warm up supply air and humidify it. Water vapour from the humid extract air is condensed and absorbed by the heat

exchanger plates. The recovered humidity and heat are transferred to the supply air flow. The air streams are fully separated within the

heat exchanger and the microbes and smells are isolated.

LEFT-HANDED AND RIGHT-HANDED MODIFICATIONS

The figure below shows the arrangement of spigots for left- and right-handed modifications. Choosing the right arrangement can

improve the ease of installation, shorten the length of the ducts and reduce the number of air duct bends (elbows)

R

EXTRACT AIR

SUPPLY AIR

INTAKE AIR

EXHAUST AIR

INTAKE AIR

SUPPLY AIR

EXHAUST AIR

EXTRACT AIR

Left-handed modification

Right-handed modification

Left-handed modification