11

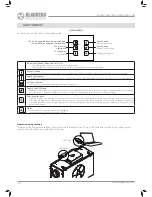

S14 SENSOR CONTROL PANEL MOUNTING

MAKE SURE THAT THE CONTROL PANEL IS NOT DAMAGED. DO NOT USE A DAMAGED

CONTROL PANEL! DO NOT INSTALL THE CONTROL PANEL ON AN UNEVEN SURFACE!

WHILE TIGHTENING THE SCREWS, DO NOT APPLY EXCESSIVE FORCE TO PREVENT THE

CONTROL PANEL CASING DEFORMATION.

Control panel wall flush mounting:

Control panel wall surface mounting:

1.

Make a hole in the wall to

install the control panel.

Insert all the necessary cables

and wires into the hole, install

the mounting box from the

delivery set in the wall.

2.

Use a screwdriver to carefully

undo the clips on the

backside of the control panel

and remove the back cover.

3.

Fix the back side of the casing

to the mounting box through

the mounting holes, then

connect the cable to the

control panel in accordance

with the Wiring diagram.

4.

Fix the front side of the

control panel using the

latches.

1.

1. Lead all necessary cables

and wires to the control panel

mounting place and install

the mounting box from the

delivery set on the wall.

2.

Use a screwdriver to carefully

undo the clips on the

backside of the control panel

and remove the back cover.

3.

Fix the back side of the casing

to the mounting box through

the mounting holes using two

screws from the delivery set.

Then connect the cable to the

control panel in accordance

with the Wiring diagram.

4.

Fix the front side of the

control panel using the

latches.