TECHNICAL MAINTENANCE

DISCONNECT THE UNIT FROM POWER SUPPLY BEFORE ANY MAINTENANCE

OPERATIONS!

MAKE SURE THE UNIT IS DISCONNECTED FROM POWER MAINS BEFORE REMOVING

THE PROTECTION

Technical maintenance and repair of the fan may commence only after its disconnection from the power mains and after all rotating

parts are at a complete standstill. Prior to commencing any technical maintenance put up a prohibitory sign on the fan starting panel:

«Do not switch on! Men at work!» The technical maintenance includes periodic cleaning of the surfaces from accumulated dust and

dirt.

Technical maintenance must be carried out at least once a year.

• Check the grounding screw terminals and electric connectors for proper tightness and tighten them up if necessary.

• Check the fastening screws for tightness and tighten them up if necessary.

• Check the bolt connecting the motor shaft to the hub for proper tightness and tighten it up if necessary.

• Check the fan impeller for contamination and clean it up if necessary. To clean the impeller, the outer lining segment must be

removed.

Cut off power supply when doing work related to the safety of maintenance. Other work related to electrical characteristics must be

performed with the power supplied.

AVOID LIQUID SPILLS ON THE MOTOR! DO NOT USE AGGRESSIVE SOLVENTS AND

SHARP OBJECTS FOR CLEANING!

PRIOR TO COMMENCING ANY TECHNICAL MAINTENANCE PUT UP A PROHIBITORY

SIGN ON THE FAN STARTING PANEL:

“DO NOT SWITCH ON! MEN AT WORK!”

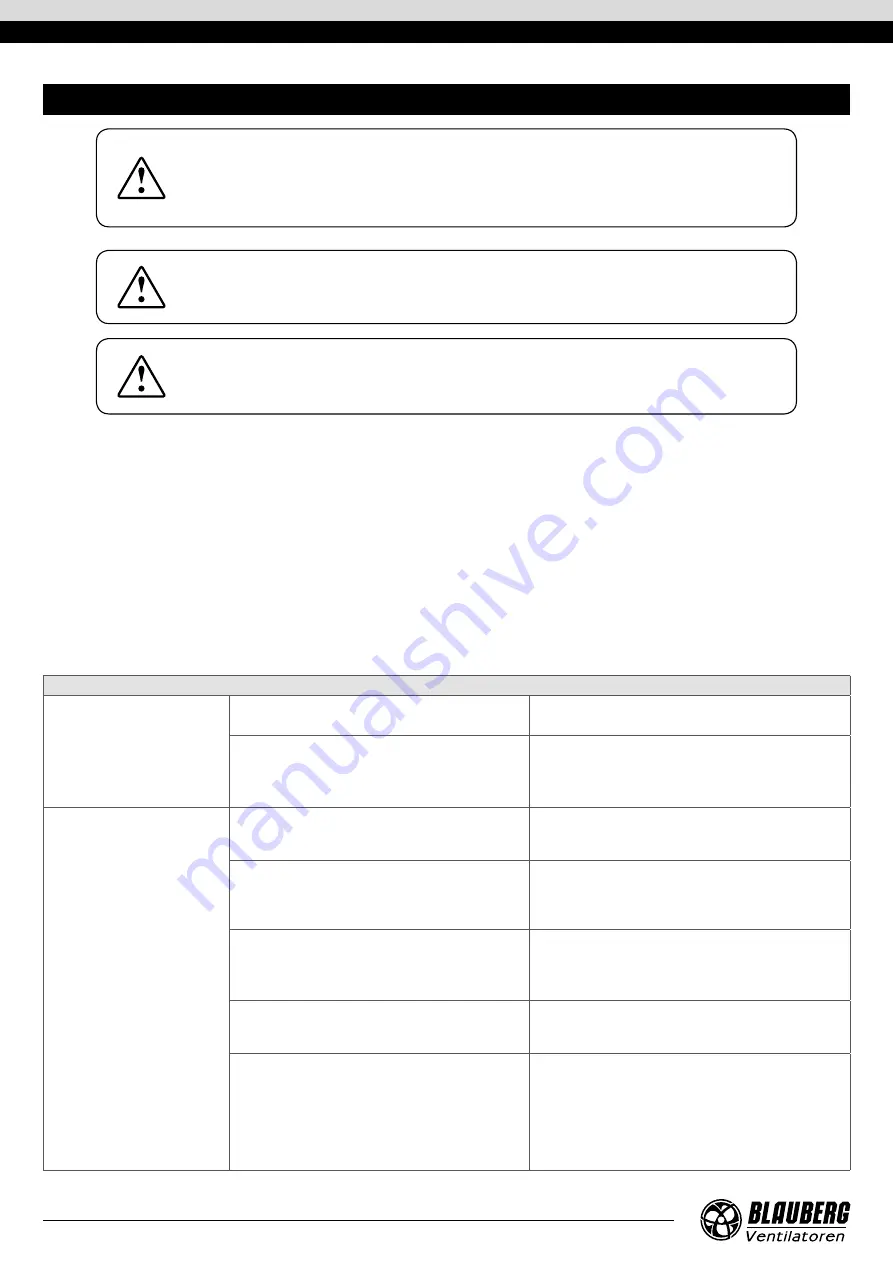

POSSIBLE MALFUNCTIONS AND THEIR ELIMINATION

Problem

Possible reasons

Elimination

The fan will not start.

No power supply.

Check the mains switch. Check the electrical connections

against the wiring diagram.

Jammed motor.

Carefully check the fan impeller for possible seizure and

eliminate it, if necessary. If the impeller is in order, replace

the electric motor.

The switching equipment

activates upon fan start-up.

Short circuit in the fan or the electric circuit between

the fan and the switching equipment.

Eliminate the cause of a short circuit.

Excessive current consumption due to an overload in

the electric mains.

Eliminate the cause of excessive current consumption.

Improper fan starting method.

Use a soft starter or frequency converter to start the motor

(see "Asynchronous Electric Motor Starting Methods"

in the "Connection to power mains" section)

.

Improper switching equipment.

Re-select the switching equipment in accordance with the

current regulations and equipment specifications.

The installed switching equipment is of poor quality

or its actual performance falls short of the rated values

stated by the manufacturer.

Re-select the switching equipment by choosing a unit

which successfully passed commutation and load tests

and has a technical compliance certificate. The selection

should be limited to the top five foreign switching

equipment manufacturers.

www.blaubergventilatoren.de

tower-sV-k2

14