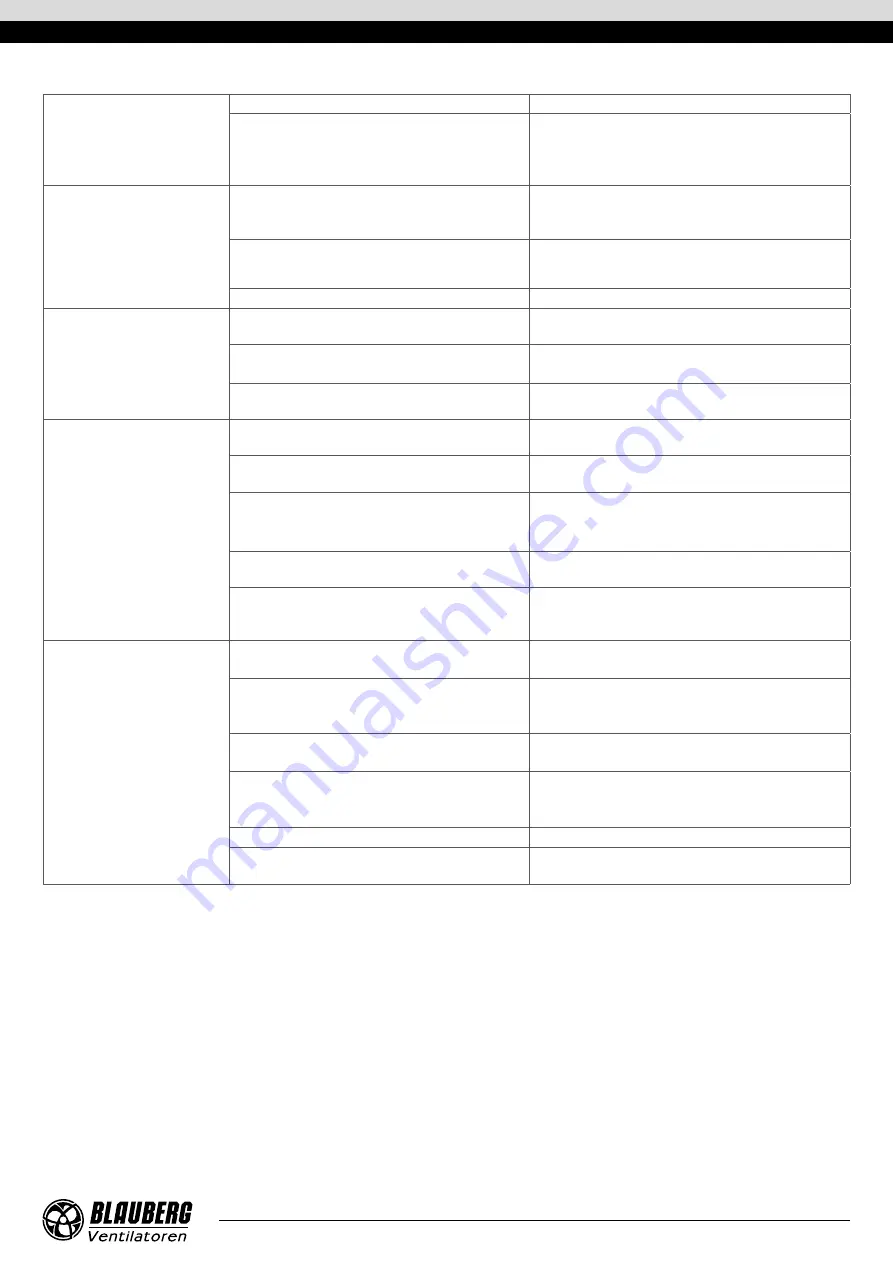

The fan fails to reach the

required rotation speed due to

serious overheating of the fan

motor.

Fan motor overloaded.

Eliminate the overload.

Improper fan starting method.

Use a soft starter or frequency converter to start the motor

(see “Asynchronous Electric Motor Starting Methods”

in the “Connection to power mains” section)

.

The fan motor runs at

overload capacity with current

consumption in excess of the

rated value.

The fan supplies more air than expected upon motor

capacity selection.

Measure network resistance. Throttle down the network

(add aerodynamic resistance to the air duct network).

Wrong motor phasing. The impeller rotates in the

opposite direction of the arrow on the fan casing.

If necessary, change the impeller rotation direction by

changing the phase sequence on the electric motor

terminals.

Air ducts clogged.

Clean the air duct or the impeller.

The fan supplies more air than

expected.

The resistance values used during the ventilation

network calculations are too conservative.

Check the air ducts for proper shape and cross section as

well as for any dampers present.

The cross section of air ducts increased and their

number reduced during the installation.

Throttle down the network (add aerodynamic resistance

to the air duct network).

Wrong choice of the fan.

Replace the fan with a unit of proper standard size.

The fan supplies less air than

expected.

Wrong calculation of the ventilation network and

wrong selection of the fan.

Re-calculate the network parameters and select a

matching fan.

The network resistance exceeds the design

calculations.

Re-arrange the ventilation network to decrease its

aerodynamic resistance.

Wrong direction of the impeller rotation.

If necessary, change the impeller rotation direction by

changing the phase sequence on the electric motor

terminals

(see the “Commissioning” section)

.

Air leak through a loose air duct connection.

Eliminate the air leak. Seal the air duct connection.

Impeller or air duct contamination with foreign

objects or debris.

Clean the impeller or the air ducts from foreign objects or

debris.

Excessive noise or vibration both

inside the fan and in the circuit.

Loose screw connections.

Check the screw connections for proper tightness.

No flexible joints between the fan and the ventilation

network on the suction and discharge sides.

Install flexible joints.

Loose connection of valves and dampers to the air

ducts.

Tighten up the fasteners of valves and dampers.

Impeller or air duct contamination with foreign

objects or debris.

Clean the impeller or the air ducts from foreign objects or

debris.

Worn bearings.

Replace the bearings.

Unstable power supply, unstable motor operation.

Check the stability of power supply parameters and

electric motor operation.

www.blaubergventilatoren.de

tower-sV-k2

15